Feeding product for injection molding of titanium and titanium alloy and preparation method thereof

An injection molding and titanium alloy technology, applied in the field of titanium hydride powder injection molding feed products and its preparation, can solve the problems of complex degreasing, environmental pollution, etc., and achieve good compatibility, simple and convenient removal, and less defects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

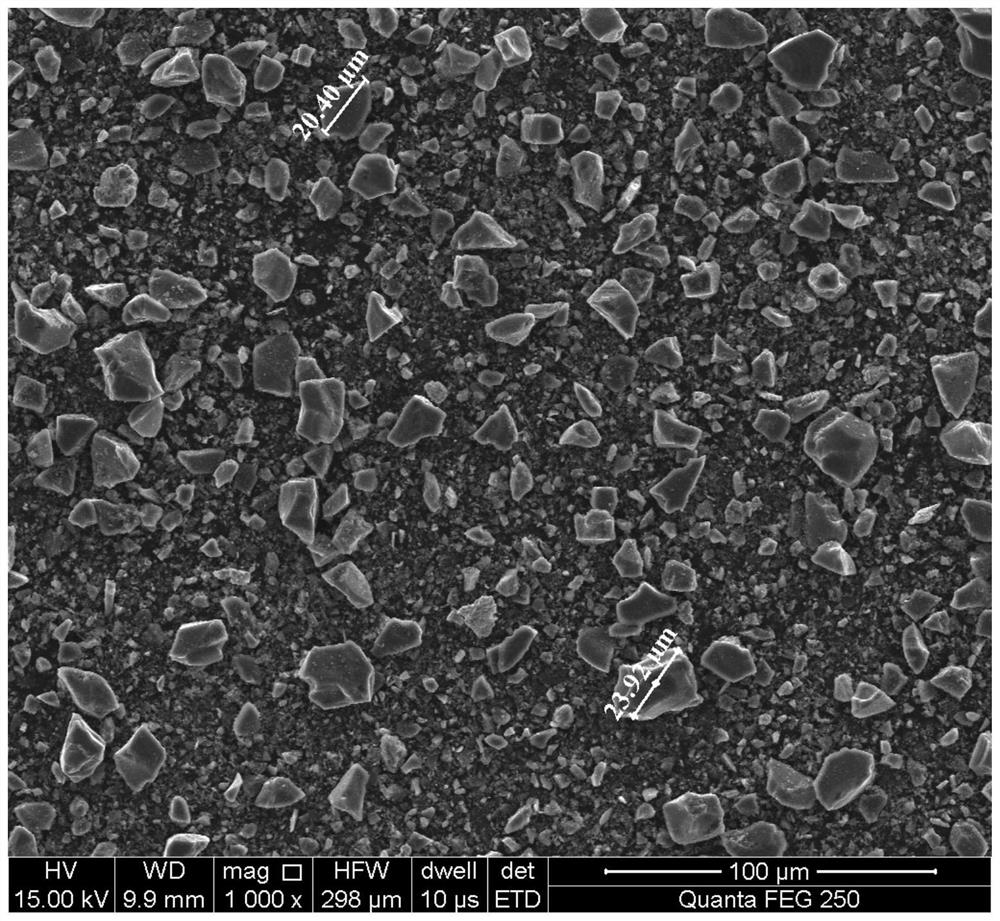

[0024] 1. The raw material titanium hydride powder (particle size range 500 ~ 800mm) placed in a drum mill, 6.5kg mass of the powder, stainless steel ball mass 15kg, evacuated three times with argon atmosphere for protection, the milling time was 2h, after milling through a 325 mesh powder sieve sieved, to give hydrogen-containing powder particle size range D50: 20 ~ 25μm.

[0025] 2. The mixed powder was sieved with a binder, which accounted for 60% of the powder, accounting for 40% of a binder, the binder component is a polyethylene glycol (PEG) accounting for 65%, polymethacrylic acid methyl ester (PMMA) accounting for 6.7% polyvinyl butyral (PVB) accounting for 20%, ethylene - vinyl acetate copolymer (EVA) accounted for 3.3%, stearic acid (SA) accounted for 2% of paraffin accounting for 3%.

[0026] 3. The mixed powder mixing, the temperature is 200 ℃, time 3h, repeated three times and stirred under a hammer, and finally cooled to obtain feed.

[0027] 4. Feeding injection int...

Embodiment 2

[0031] 1. The raw material titanium hydride powder (particle size range 500 ~ 800mm) placed in a drum mill, 6.5kg mass of the powder, stainless steel ball mass 15kg, evacuated three times with argon atmosphere for protection, the milling time was 1.5h, after the milled powder through 325 mesh sieved, to give hydrogen-containing powder particle size range D50: 20 ~ 25μm.

[0032] 2. The sieved powder was mixed with a binder, wherein the powder accounted for 55%, accounting for 45% binder. Binder component is a polyethylene glycol (PEG) accounting for 65%, polymethyl methacrylate (PMMA) accounting for 6,7%, polyvinyl butyral (PVB) accounting for 20%, ethylene - vinyl acetate ethylene copolymer (EVA) accounted for 3.3%, stearic acid (SA) accounted for 2%, 3% Paraffin accounting.

[0033] 3. The mixed powder mixing, the temperature is 200 ℃, time 3h, repeated three times and stirred under a hammer, and finally cooled to obtain feed.

[0034] 4. Feeding injection into an injection mold...

Embodiment 3

[0038] 1. The raw material titanium hydride powder (particle size range 500 ~ 800mm) placed in a drum mill, 6.5kg mass of the powder, stainless steel ball mass 15kg, evacuated three times with argon atmosphere for protection, the milling time was 1.5h, after the milled powder through 325 mesh sieved, to give hydrogen-containing powder particle size range D50: 20 ~ 25μm.

[0039]2. Mix the powder after sieve with the binder, wherein the powder accounts for 55%, and the binder is 45%. The binder component is polyethylene glycol (PEG) to 65%, polymethyl methacrylate (PMMA) accounts for 10%, polyvinyl butyral (PVB) accounts for 15%, ethylene-vinyl acetate copolymerization (EVA) accounts for 5%, and stearic acid (SA) accounts for 2%, and the paraffin is 3%.

[0040] 3. The mixed powder is carried out with a high temperature, the temperature is 200 ° C, the time is 3 h, and the hammer is stirred repeated three times, and finally cools to obtain feed.

[0041] 4. Feeding into the syringe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com