Composite hydrogen storage material NaBH4@NiCo-NC and preparation method thereof

A hydrogen storage material, 2·6H2O technology, applied in chemical instruments and methods, hydrogen, inorganic chemistry, etc., can solve the problem of high hydrogen desorption temperature, and achieve the effects of low hydrogen desorption temperature, convenient synthesis, and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

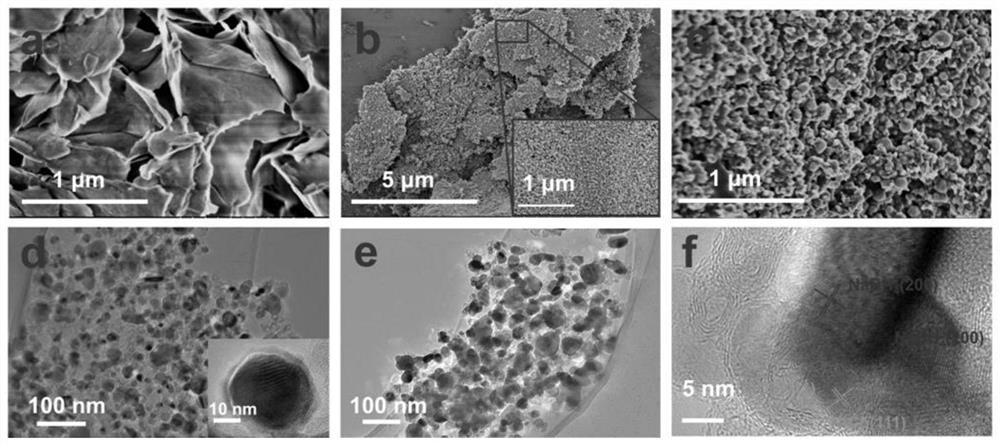

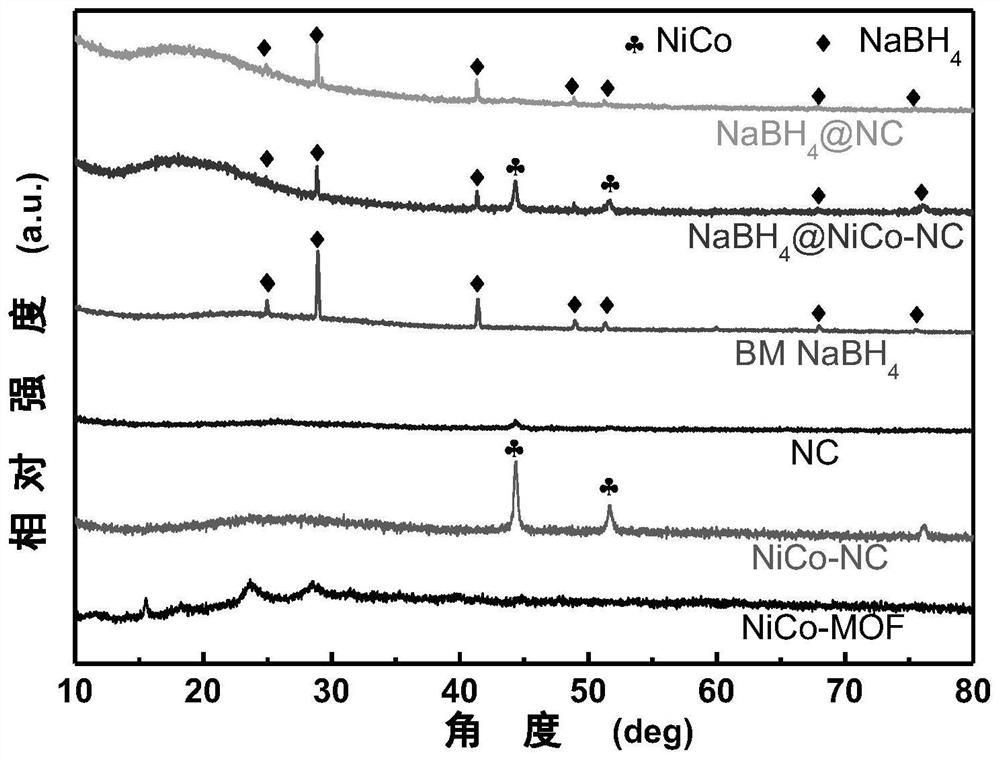

[0038] (1) Preparation of flake NiCo-MOFs

[0039] At room temperature (25°C), 0.75 mmol Ni(NO 3 ) 2 ·6H 2 O, 0.75 mmol Co(NO 3 ) 2 ·6H 2 O and 1.5 mmol terephthalic acid were dissolved in a mixed solution consisting of 4 mL ethanol, 4 mL water, and 64 mL N,N dimethylformamide. To it was quickly added 1.6 mL of triethylamine and stirred for 5 minutes. The product was placed in an ultrasonic machine, and the ultrasonic wave was continued for 8 h. After centrifuging three times with ethanol, the product was dispersed in water and sonicated for 30 minutes. The dispersed product was freeze-dried for 72 h, and the final product was NiCo-MOFs nanosheet material.

[0040] (2) Preparation of NiCo-NC porous nanosheets

[0041] The freeze-dried NiCo-MOFs were placed in a tube furnace. Under an argon atmosphere, the temperature was raised to 900 °C at a rate of 2 °C / min, kept for 1 h, and the product obtained after cooling was NiCo-NC.

[0042] (3) NaBH with 50% load 4 Prepara...

Embodiment 2

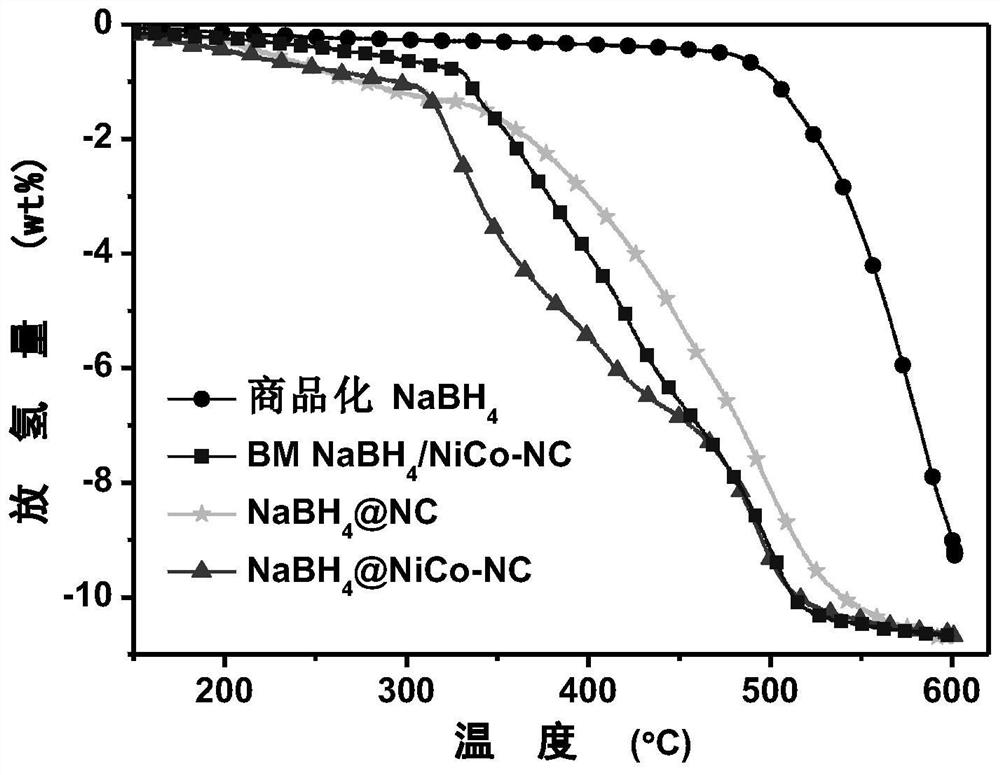

[0046] Prepare NiCo-NC porous nanosheets by the same method as step (1) and step (2) in Example 1, in an argon glove box, 30 mg NaBH 4 It was added to 15 mL of diethylene glycol dimethyl ether, and after stirring for 1 h, a transparent and clear solution was obtained. After adding 20 mg of NiCo-NC to it, continue to sonicate in the ultrasonic machine for 0.5 h, transfer the ultrasonic product to the reaction tube, drain the solvent at 80 °C and continue to vacuum for 12 h, the obtained product is 60 %loaded NaBH 4 @NiCo-NC. At 400 °C, the prepared NaBH with 60% loading 4 @NiCo-NC can emit 7.4 wt% within 6h (relative to NaBH 4 quality) of hydrogen, much higher than commercial NaBH 4 The amount of hydrogen released (1.3 wt%) at 440 °C for 6 h.

Embodiment 3

[0048] Prepare NiCo-NC porous nanosheets with the same method as step (1) and step (2) in Example 1, in an argon glove box, 40 mg NaBH 4 It was added to 20 mL of diethylene glycol dimethyl ether, and after stirring for 1 h, a transparent and clear solution was obtained. After adding 20 mg NiCo-NC to it, continue to sonicate in the ultrasonic machine for 0.5 h, transfer the sonicated product to the reaction tube, drain the solvent at 80 °C and continue vacuuming for 12 h, the obtained product is 67 % loaded NaBH 4 @NiCo-NC. At 400 °C, the prepared NaBH with 67% loading 4 @NiCo-NC can emit 7.5 wt% within 6h (relative to NaBH 4 quality) of hydrogen, much higher than commercial NaBH 4 The amount of hydrogen released at 440°C for 6h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com