Method for preparing hexagonal crystal system hydroxyl lanthanum carbonate by adopting hydrothermal synthesis

A technology of lanthanum hydroxycarbonate and hexagonal crystal system, which is applied in the preparation/processing of rare earth metal compounds, rare earth metal carbonate, etc., can solve the problem of increasing the difficulty and cost of preparation, the hexagonal lanthanum hydroxycarbonate has no relevant instructions, and the auxiliary materials are special. And other problems, to achieve the effect of low price, stable product quality, and increase the cost of auxiliary materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] In the precipitation reactor, use deionized water to prepare the lanthanum chloride solution into a bottom solution with a concentration of 0.7mol / L, add 30% lanthanum carbonate as a seed crystal, and after stirring evenly, use the co-current precipitation method to control the addition of chloride The flow rate of lanthanum feed liquid and precipitant (ammonium bicarbonate solution); feed liquid concentration is 1.5mol / L, precipitant concentration is 3mol / L, reaction temperature is controlled at 32°C, reaction time is 6h, precipitation endpoint pH=6.7.

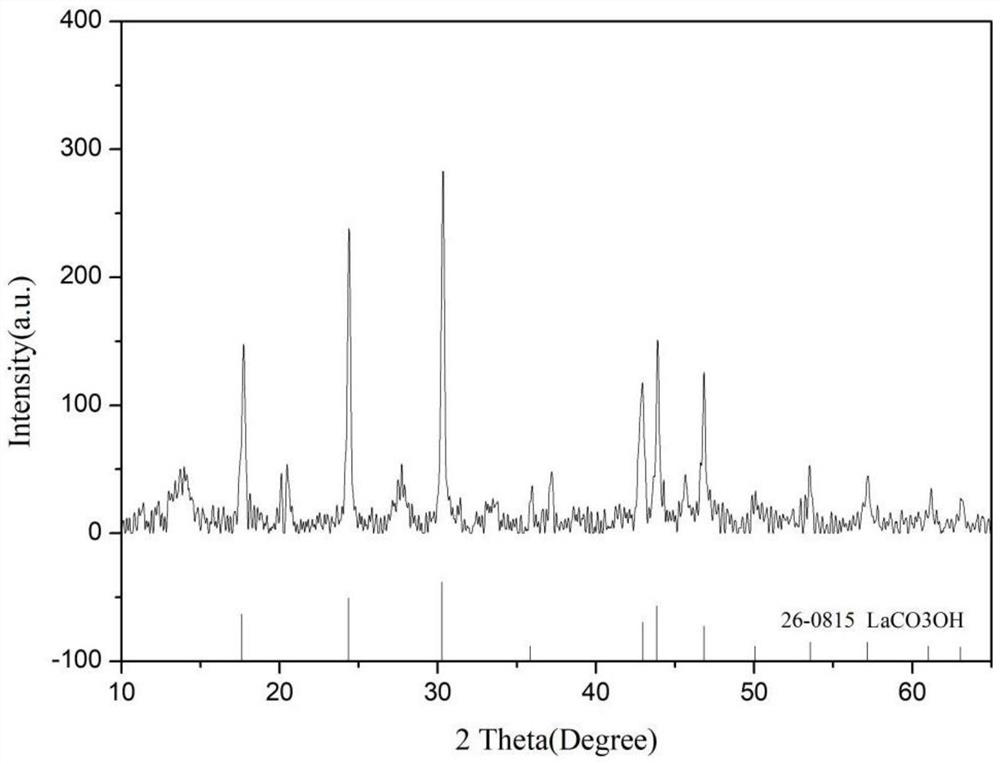

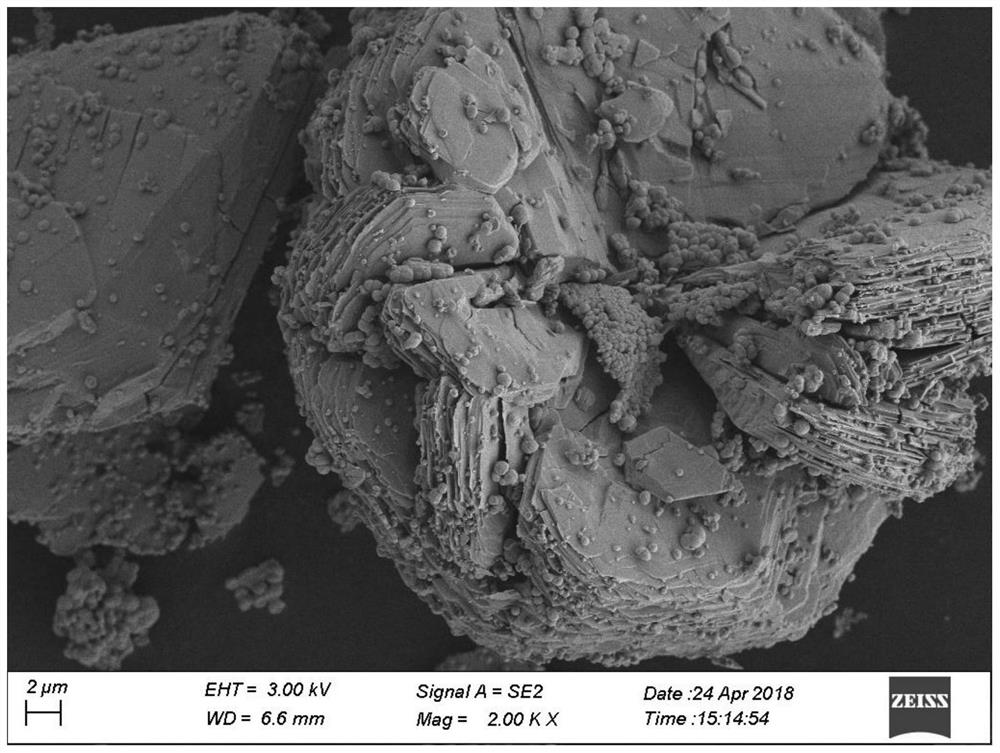

[0049] After filtering, the filter cake was rinsed with deionized water and vacuum-dried to obtain lanthanum carbonate. Add lanthanum carbonate and deionized water into the reactor in a mass ratio of 1:4, control the reaction temperature at 110°C, keep it warm for 20 hours, wash the obtained product with deionized water, put it in an oven, and dry it at 150°C for 12 hours , to obtain hexagonal basic lanthanum carbonate...

Embodiment 2

[0053] Use deionized water to prepare the lanthanum chloride solution as a bottom solution with a concentration of 0.5mol / L, add 20% lanthanum carbonate as a seed crystal, and after stirring evenly, adopt a co-current precipitation method to simultaneously control the addition of lanthanum chloride feed solution and precipitation Agent (mixed solution of ammonium bicarbonate and ammonia water) and control the flow rate, the concentration of the precipitating agent is 2mol / L, the reaction temperature is controlled at 48°C, the reaction time is 8h, and the pH of the precipitation end point is 6.5.

[0054] After filtering, the filter cake was rinsed with deionized water and vacuum-dried to obtain lanthanum carbonate. Add lanthanum carbonate and deionized water into the reactor in a mass ratio of 1:3, control the reaction temperature at 150°C, keep it warm for 10 hours, wash the obtained product with deionized water, put it in an oven, and dry it at 180°C for 8 hours , to obtain ...

Embodiment 3

[0056] Use the supernatant of the previous batch to prepare the lanthanum chloride solution into a bottom solution with a concentration of 0.3mol / L, add 40% lanthanum carbonate as a seed crystal, and stir evenly, and then control the addition of lanthanum chloride material at the same time by means of co-current precipitation The flow rate of liquid and precipitant (mixed solution of ammonium bicarbonate and ammonia water); the concentration of feed liquid is 1.8mol / L, the concentration of precipitant is 4mol / L, the reaction temperature is controlled at 40°C, the reaction time is 12h, and the pH of the precipitation end point is 6.7.

[0057] After filtering, the filter cake was rinsed with deionized water and vacuum-dried to obtain lanthanum carbonate. Add lanthanum carbonate and deionized water into the reactor at a mass / volume ratio of 1:6, control the reaction temperature at 130°C, and keep it warm for 11 hours. The obtained product is washed with deionized water and placed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com