Resin capable of remolding and degrading biomass benzoxazine and preparation method of resin

A benzoxazine and biomass technology, applied in the field of functional polymer materials, can solve the problems that cannot meet the requirements, there is no degradable biomass benzoxazine resin, and the heat resistance is low, so as to save processing costs, The effect of easy industrialized large-scale production and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

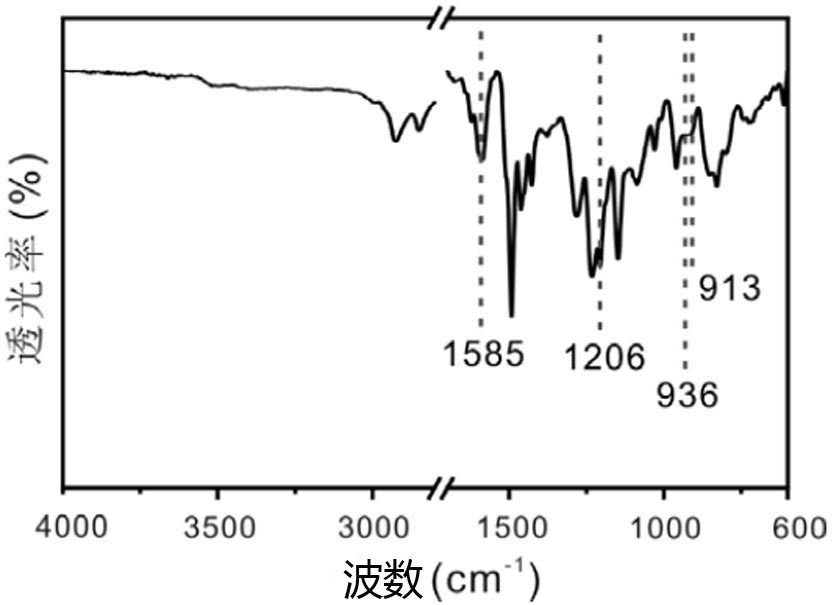

[0043] (1) Preparation of benzoxazine monomers

[0044] At room temperature, 3.28 g of isobutylphenol, 1.20 g of polymethylene formaldehyde (CAS #: 30525-89-4) and 1.72 g of decanamine were added to 50 ml round bottom flask, then stirred at 100 ° C for 5 h, then naturally Cooled to room temperature to give a crude product; the crude product was recrystallized to give a white solid (4.15 g, yield of 76%), which was recorded as a total substance benzoxazine monomer (IE-DEA), 1 H NMR (400 MHz, ChlorOform-D) δ 6.75 (S, 2H, Ar-H), 6.55 (S, 2H, Ar-H), 6.30 (D, J = 15.5, 2H, CH), 6.11-6.03 ( M, 2H, CH), 4.96 (S, 4H, CH 2 ), 3.98 (s, 4h, ch 2 ), 3.90 (s, 6h, ch 3 ), 2.82-2.71 (m, 4h, ch 2 ), 1.91-1.84 (m, 6h, ch3 ), 1.60-1.52 (p, j = 7.1 hz, 4h, ch 2 ), 1.35-1.24 (m, 12h, ch 2 ). 13 C NMR (101MHz, CDCL 3 δ 147.6, 142.7, 130.6, 130.7, 106.6, 82.9, 55.7, 51.4, 50, 29.5, 29.5, 28.2, 27.2, 18.4. HRMS (ESI + ) M / Z Calcd FORC 34 Hide 49 N 2 O 4 K + [M + K + H] + : 588.3324, Found: 588.4171. I...

Embodiment 2

[0073] (1) Preparation of benzoxazine monomers

[0074] The isoeugenol 3.28g, 1.20 g of paraformaldehyde (CAS #: 30525-89-4) and added to 1.72g decanediamine 50mL round bottom flask and the reaction was then heated to 100 deg.] C, incubation was stirred 5h, then cooled to room temperature to give a crude product; the crude product with ethyl acetate (20mL) was recrystallized to give a white solid, referred to as a benzoxazine monomer.

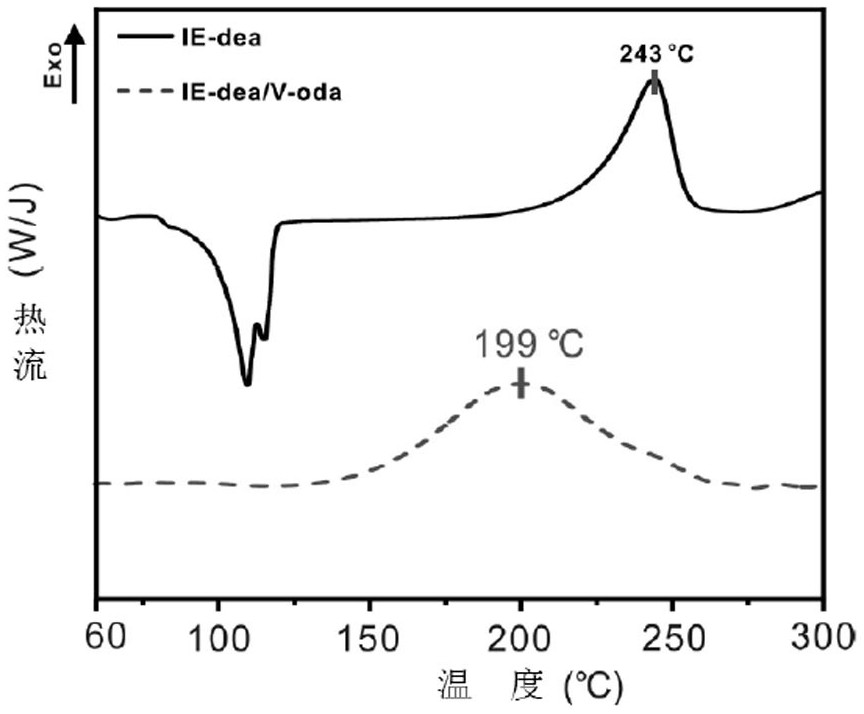

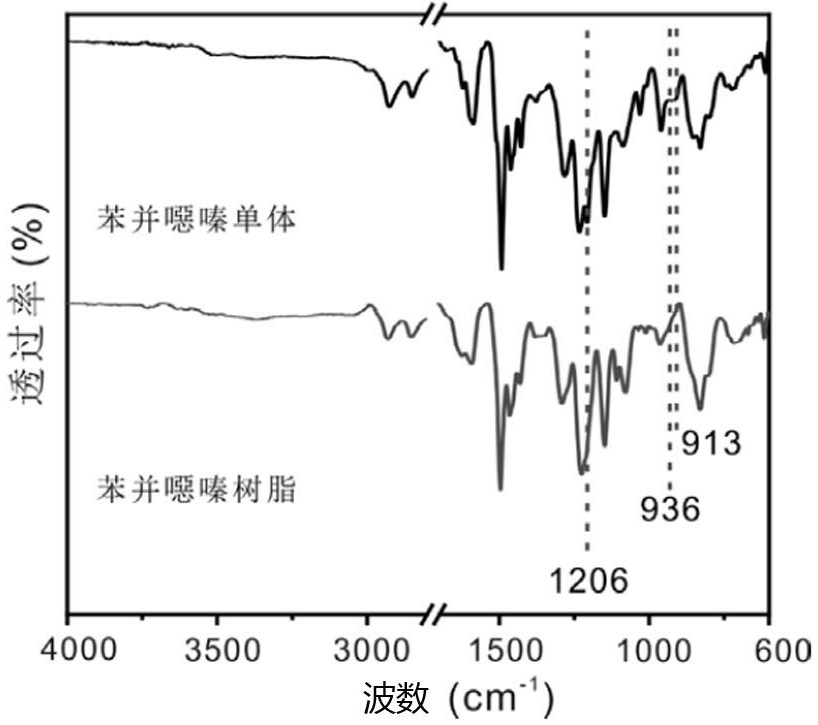

[0075] (2) Preparation of resin and remodelable biomass degradation benzoxazin

[0076] 10.0g of biomass benzoxazine monomer / Schiff base (V-oda) blend (molar ratio of 1) was melted (160 ℃) 15min, and the resin poured into a mold in an oven degassing (at 150 ℃ 10min), and the mold was placed after the drying oven, and cured in accordance with the sequence 160 ℃ / 3h + 180 ℃ / 3h + 200 ℃ / 3h process; after curing, oven with natural cooling, to obtain remodeling and degradation of the biomass may be benzoxazine resins.

[0077] The above and degrad...

Embodiment 3

[0080] (1) Preparation of benzoxazine monomer

[0081] The isoeugenol 3.28g, 1.32 g of paraformaldehyde (CAS #: 30525-89-4) and added to 1.72g decanediamine 50mL round bottom flask and the reaction was then heated to 100 deg.] C, incubation was stirred 8h, then cooled to room temperature to give a crude product; the crude product with ethyl acetate (20mL) was recrystallized to give a white solid, referred to as a benzoxazine monomer.

[0082] (2) Preparation of resin and remodelable biomass degradation benzoxazin

[0083] 10.0g of biomass benzoxazine monomer / Schiff base (V-oda) blend (molar ratio of 1) was melted (150 ℃) 15min, and the resin poured into a mold in an oven degassing (at 150 ℃ 10min), and the mold was placed after the drying oven, and cured in accordance with the sequence 160 ℃ / 1h + 180 ℃ / 1h + 200 ℃ / 1h process; after curing, oven with natural cooling, to obtain remodeling and degradation of the biomass may be benzoxazine resins.

[0084] The above and degrada...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Storage modulus | aaaaa | aaaaa |

| Tensile modulus | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com