Colorful tempered floor and preparation method thereof

A colorful steel and tempering technology, used in paints, coatings, antifouling/underwater coatings containing biocides, etc., can solve the problems of low overall hardness and wear resistance, no three-dimensional effect, poor decorative effect, etc. To achieve the effect of good decorative effect, prominent three-dimensional effect and strong three-dimensional effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

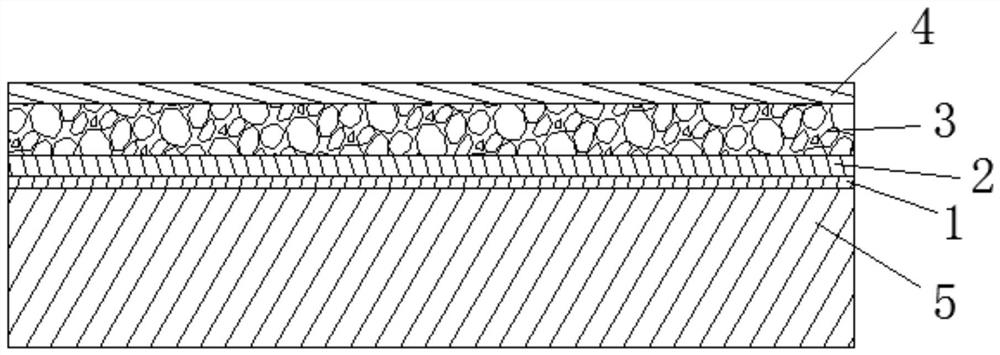

[0039] The preparation method of colorful tempered floor comprises the following steps:

[0040] (1) Lay a primer layer on the surface of the concrete base;

[0041] (2) Lay epoxy mortar leveling layer on the surface of primer layer;

[0042] (3) Lay colored layer on the surface of epoxy mortar leveling layer, the surface of described colored layer forms concavo-convex surface;

[0043] (4) Lay a tempered finish paint layer on the surface of the colored layer.

Embodiment 1

[0045] Embodiment 1 of the present invention provides a colorful tempered floor, including a primer layer, an epoxy mortar leveling layer, a color layer and a tempered finish paint layer.

[0046] The primer layer is composed of the following raw materials in parts by mass:

[0047] 5 parts of water; 1 part of thickener; 3 parts of titanium dioxide; 3 parts of silver zeolite; 2 parts of color paste; 10 parts of alkali-resistant epoxy ethylene resin; 12 parts of modified hydroxyethyl cellulose ether;

[0048] The epoxy mortar leveling layer is composed of the following raw materials in parts by mass:

[0049] 100 parts of epoxy resin; 20 parts of Portland cement; 20 parts of aluminate cement; 8 parts of quartz sand; 2 parts of acrylate; 5 parts of silicon crystal curing agent; 2 parts of talcum powder;

[0050] The colored layer consists of the following raw materials in parts by mass:

[0051] 100 parts of polyurethane modified epoxy resin; 10 parts of colored quartz sand; 1...

Embodiment 2

[0056] Embodiment 2 of the present invention provides a colorful tempered floor, including a primer layer, an epoxy mortar leveling layer, a color layer and a tempered finish paint layer.

[0057] The primer layer is composed of the following raw materials in parts by mass:

[0058] 6 parts of water; 1 part of thickener; 4 parts of titanium dioxide; 4 parts of silver zeolite; 3 parts of color paste; 20 parts of alkali-resistant epoxy ethylene resin; 15 parts of modified hydroxyethyl cellulose ether;

[0059] The epoxy mortar leveling layer is composed of the following raw materials in parts by mass:

[0060] 100 parts of epoxy resin; 30 parts of Portland cement; 20 parts of aluminate cement; 10 parts of quartz sand; 5 parts of acrylate; 8 parts of silicon crystal curing agent; 5 parts of talcum powder;

[0061] The colored layer consists of the following raw materials in parts by mass:

[0062] 100 parts of polyurethane modified epoxy resin; 30 parts of colored quartz sand; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com