High-brightness chromogenic film as well as preparation method and application thereof

A high-brightness, thin-film technology, applied in nanotechnology, optics, instruments, etc. for materials and surface science, can solve the problems of complex preparation methods and low brightness of color-producing films

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

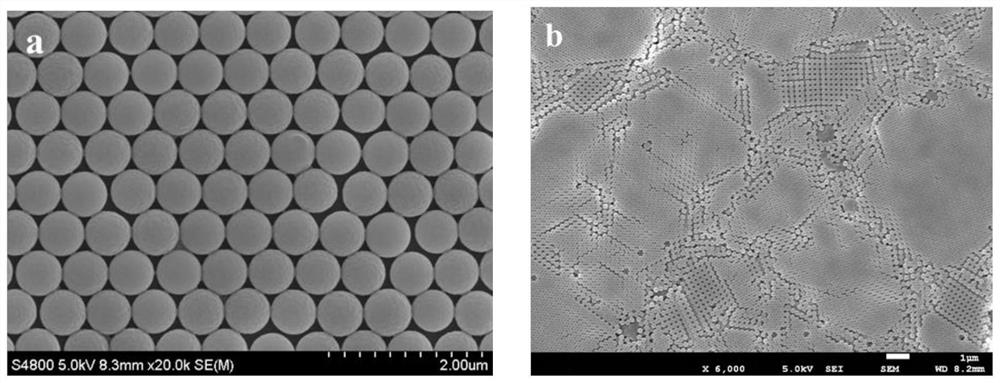

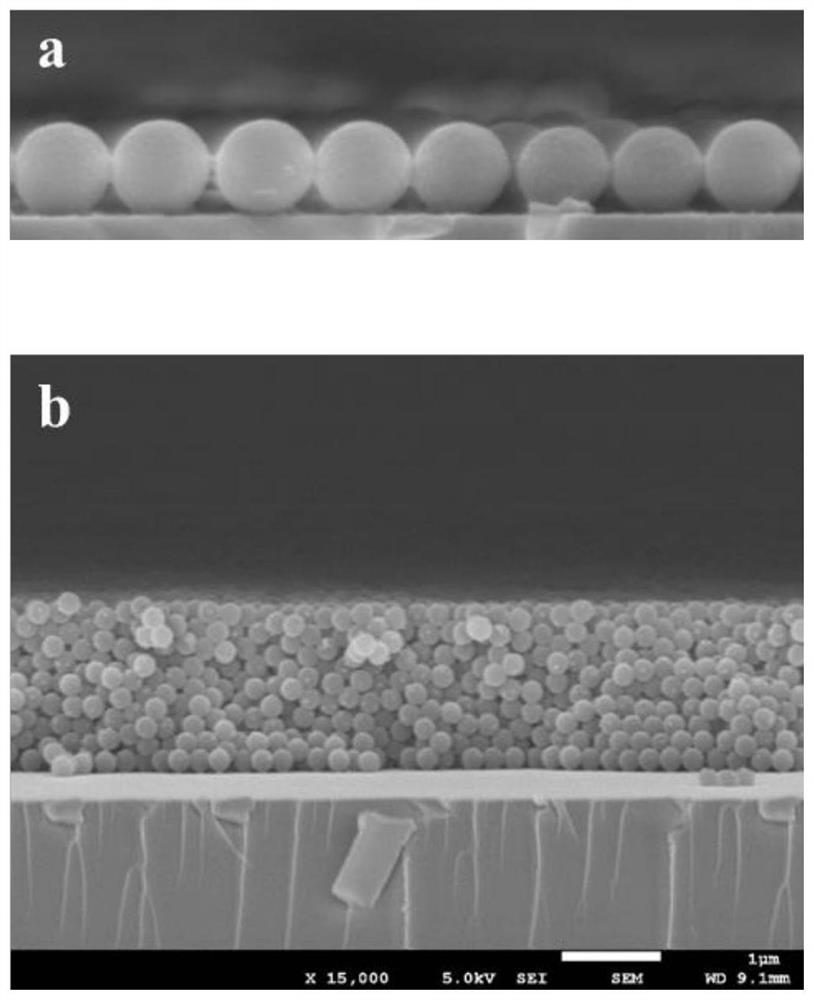

[0065] The second aspect of the present invention provides a method for preparing the high-brightness color-forming film of the present invention, wherein the method includes the following steps: using a self-assembly method to realize the assembly of nanoparticles on the surface of the substrate, that is, to obtain the high-brightness color-forming film. color film.

[0066] In the present invention, the self-assembly means that nanoparticles spontaneously form an ordered stacking structure based on the interaction of non-covalent bonds.

[0067] According to the invention, the method comprises dispersing nanoparticles in a solvent to obtain a colloid containing nanoparticles, and assembling said colloid on the surface of a substrate.

[0068] In the present invention, the solvent is not particularly limited, and may be a solvent that can well disperse the nanoparticles, such as water and / or ethanol.

[0069] Furthermore, the volume ratio of the nanoparticles, water and etha...

Embodiment 1

[0090] (1) A polystyrene bead emulsion with a mass fraction of 5% by weight and a particle size of 600nm is prepared as a mixed solution at a volume ratio of emulsion: water: absolute ethanol = 1:1:2, and ultrasonically dispersed for 10 minutes to make it uniform;

[0091] (2) Cut out a 2cm×2cm metal sheet, clean it and use oxygen plasma for hydrophilic treatment, place it in a glass petri dish, pour an appropriate amount of ultrapure water, and make the liquid level higher than the surface of the substrate and in contact with the placed silicon The slices are tangent; use a pipette gun to draw an appropriate amount of polystyrene beads mixed solution, and drop it on the silicon wafer. The rapid volatilization of ethanol in the mixed solution will drive the polystyrene beads to spread on the liquid surface and assemble. After the diffusion is complete, use a pipette gun to absorb an appropriate amount of the mixed solution and drop it on the liquid surface, and repeat it severa...

Embodiment 2

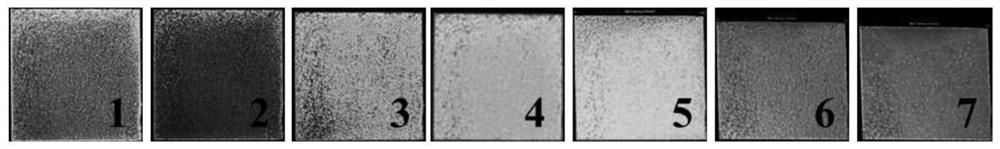

[0095] A high-brightness chromogenic film was prepared in the same manner as in Example 1, except that in step (2), the 2cm×2cm metal sheet was replaced with a 2cm×2cm silicon chip to obtain a chromogenic film S2 , its brightness and R, G, B values are shown in Table 1. Such as image 3 As shown, the chromogenic film S2 can observe different colors under different angles, specifically, Figure 3-1 displayed in purple; Figure 3-2 displayed in blue; Figure 3-3 displayed in cyan; Figure 3-4 displayed in green; Figure 3-5 displayed in yellow; Figure 3-6 displayed in orange; Figure 3-7 Displayed in red.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com