Magnetic adsorption material containing humic acid as well as preparation method and application of magnetic adsorption material

A magnetic adsorption material, humic acid technology, applied in chemical instruments and methods, adsorption water/sewage treatment, other chemical processes, etc., can solve the problems of complex operation, poor regeneration performance, low removal efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

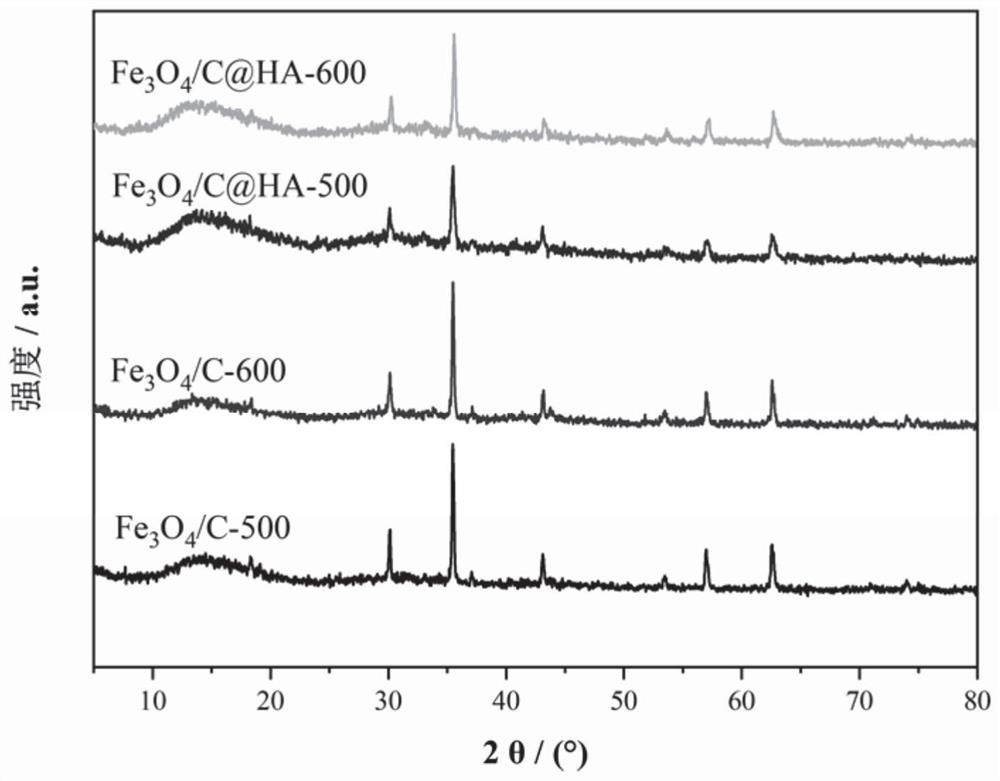

Embodiment 1

[0033] 1.0 g of iron-containing solid waste and 1.0 g of organic solid waste were mixed uniformly and dried to obtain a humic acid-containing magnetic adsorption material precursor. The precursor of the magnetic adsorption material containing humic acid was placed in a porcelain boat, heated to 500 °C for 3 h in a tube furnace with a nitrogen atmosphere, and the heating rate was 10 °C / min. Subsequently, the product obtained by calcination at N 2 After cooling to room temperature in the atmosphere, the pH of the cleaning solution was neutralized by several times of centrifugal washing. After the product was dried at 100°C, it was ground with an agate mortar and passed through a 100-mesh sieve to obtain a magnetic adsorption material (Fe 3 o 4 / C-500). Iron-containing solid waste in this embodiment is Fenton sludge (mass percentage): 31.0% Fe, 25.5% Zn, 14.7% Ca, 6.3% S, 2.6% Al, 2.5% Cu, 2.2% Si, 9.8% Cr, 1.9%P, 1.1%Cl, the balance is impurities; organic solid waste is munic...

Embodiment 2

[0036] 1.0 g of iron-containing solid waste and 1.0 g of organic solid waste were mixed uniformly and dried to obtain a magnetic adsorption material precursor. The magnetic adsorption material precursor was placed in a porcelain boat, heated to 600° C. for 3 h in a tube furnace with a nitrogen atmosphere, and the heating rate was 10° C. / min. Subsequently, the product obtained by calcination at N 2 After cooling to room temperature in the atmosphere, the pH of the cleaning solution was neutralized by several times of centrifugal washing. After the product was dried at 100°C, it was ground with an agate mortar and passed through a 100-mesh sieve to obtain a magnetic adsorption material (Fe 3 o 4 / C-600).

[0037] In this embodiment, the iron-containing solid waste is Fenton's sludge (mass percentage): In this embodiment, the iron-containing solid waste is Fenton's sludge (mass percentage): 31.0% Fe, 25.5% Zn, 14.7% Ca, 6.3% S, 2.6% Al, 2.5% Cu, 2.2% Si, 9.8% Cr, 1.9% P, 1.1%...

Embodiment 3

[0040] 1.0 g of iron-containing solid waste and 1.0 g of organic solid waste were mixed uniformly and dried to obtain a magnetic adsorption material precursor. The magnetic adsorption material precursor was placed in a porcelain boat, heated to 500° C. for 3 h in a tube furnace with a nitrogen atmosphere, and the heating rate was 10° C. / min. The product obtained by calcination is in N 2 After cooling to room temperature in the atmosphere, the pH of the cleaning solution was neutralized by several times of centrifugal washing. After the product is dried at 100°C, the magnetic adsorption material is obtained. The magnetic adsorption material is placed in a porcelain boat, and placed in a tube that is fed with humid air (humidity is 96%-98%) and the heating rate is 10°C / min. Calcined at 300°C for 0.5h in a type furnace. The product that obtains uses agate mortar to grind, crosses 100 mesh sieves, obtains containing humic acid magnetic adsorption material (Fe 3 o 4 / C@HA-500)....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com