Preparation method of stable, high-brightness and bright-colored purple CQD

A high-brightness and stable technology, applied in the field of preparation of purple CQDs, can solve the problems of non-compliance with green environmental protection, poor product stability, complex preparation conditions, etc., and achieve the effects of easy storage, not easy to return to moisture, and simple preparation conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A stable, high-brightness and bright-coloured purple CQD preparation method, the specific steps are as follows:

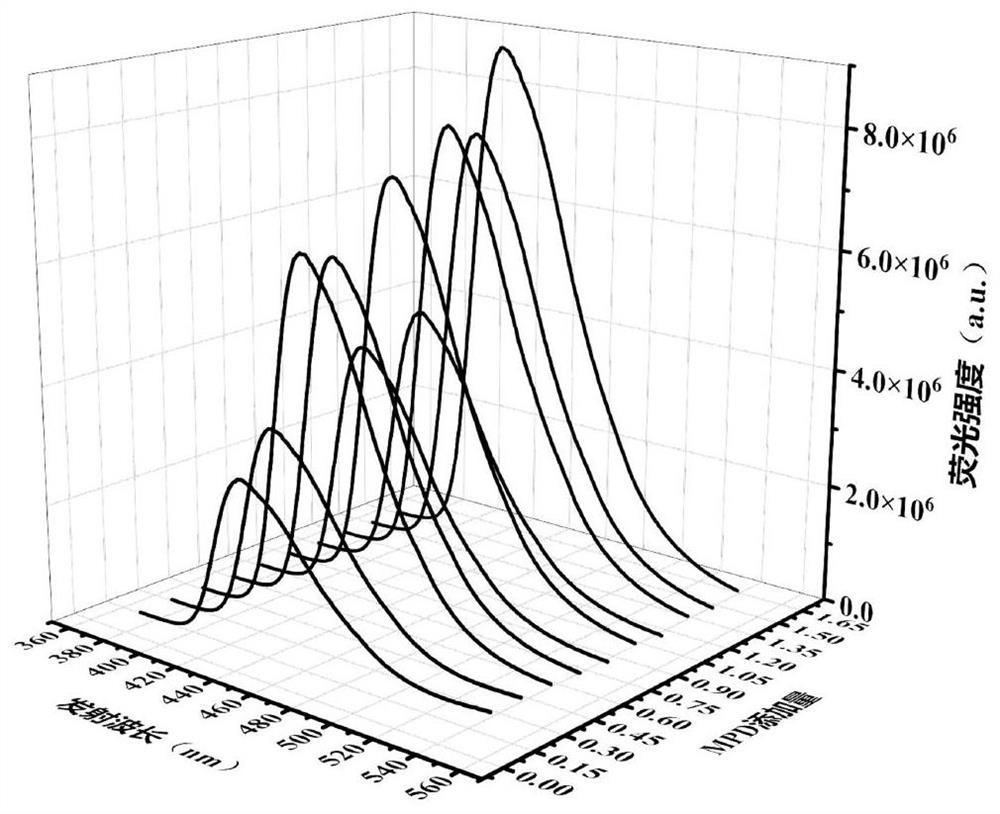

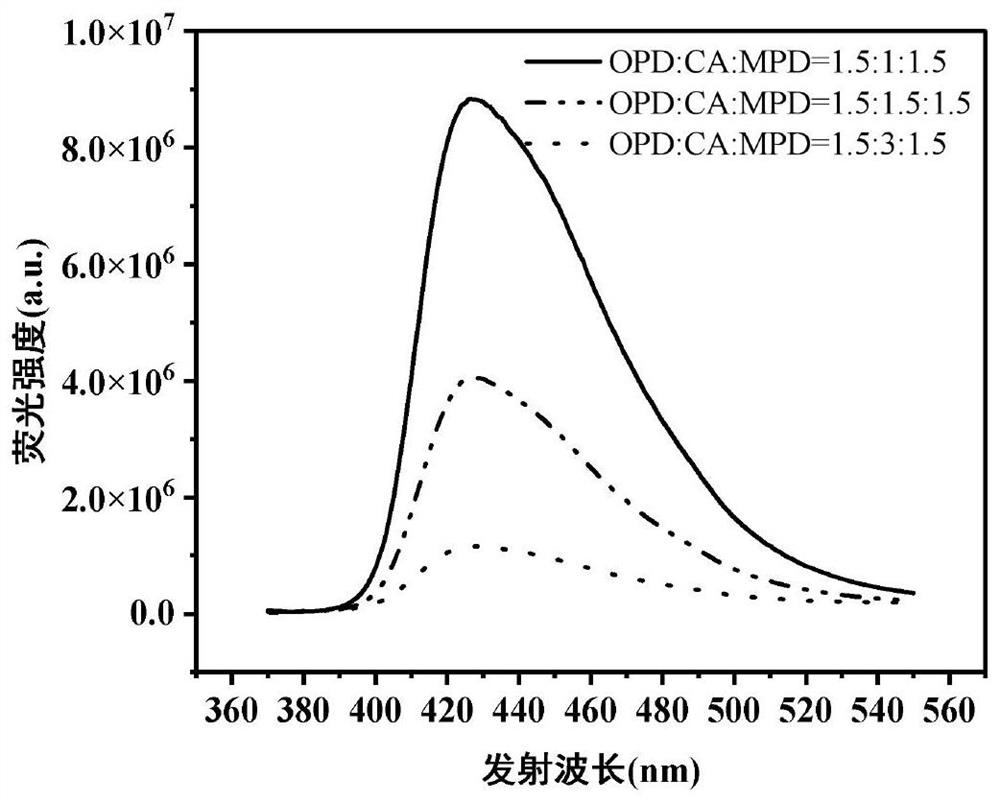

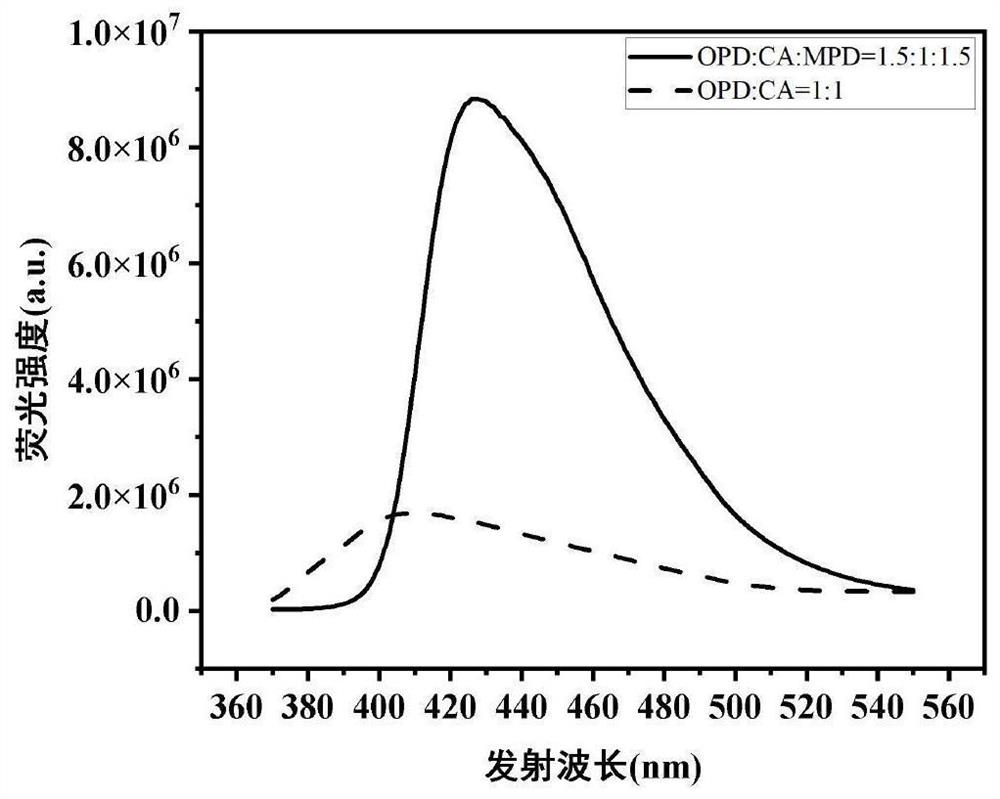

[0038] (1) After mixing CA, OPD, MPD and water to obtain the reaction solution, use sodium hydroxide to adjust the pH value of the reaction solution to 5; wherein, the molar ratio of OPD, CA and MPD is 1.5:1:1.5, and OPD and water The ratio of 324mg: 20mL;

[0039] (2) the reaction solution that the pH that step (1) obtains is 5 is joined in the polytetrafluoroethylene reactor, then the polytetrafluoroethylene reactor is put into the electric blast drying box, under normal pressure (100KPa), React at a temperature of 100°C for 8 hours, then cool the reaction liquid after the reaction to 23°C, filter it with a 0.22 μm filter membrane, and finally freeze the filtrate obtained by liquid nitrogen and freeze it in a freeze dryer. After vacuum drying for 2 d, purple CQD powders were obtained, that is, stable, high-brightness and colorful purple CQDs.

[0040] Th...

Embodiment 2

[0044] A stable, high-brightness and bright-coloured purple CQD preparation method, the specific steps are as follows:

[0045] (1) After mixing CA, OPD, MPD and water to obtain the reaction solution, use sodium hydroxide to adjust the pH value of the reaction solution to 6; wherein, the mol ratio of OPD, CA and MPD is 1.5:1.2:0.3, and OPD and water The ratio is 324mg:24mL;

[0046] (2) the reaction solution that the pH that step (1) obtains is 6 is joined in the polytetrafluoroethylene reactor, then the polytetrafluoroethylene reactor is put into the electric blast drying box, under normal pressure (100KPa), React at a temperature of 110°C for 7 hours, then cool the reaction liquid after the reaction to 24°C, filter it with a 0.22 μm filter membrane, and finally freeze the filtrate obtained by liquid nitrogen and freeze it in a freeze dryer After vacuum drying for 3 d, purple CQD powders were obtained, that is, stable, high-brightness and colorful purple CQDs.

[0047] The ...

Embodiment 3

[0049] A stable, high-brightness and bright-coloured purple CQD preparation method, the specific steps are as follows:

[0050] (1) After mixing CA, OPD, MPD and water to obtain the reaction solution, use sodium hydroxide to adjust the pH value of the reaction solution to 7; wherein, the mol ratio of OPD, CA and MPD is 1.5:1.5:0.5, and OPD and water The ratio of 324mg: 26mL;

[0051] (2) the reaction solution that the pH obtained in step (1) is 7 is added in the polytetrafluoroethylene reactor, then the polytetrafluoroethylene reactor is put into an electric blast drying box, under normal pressure (100KPa), React at a temperature of 120°C for 6 hours, then cool the reaction liquid after the reaction to 25°C, filter it with a 0.22 μm filter membrane, and finally freeze the filtrate obtained by liquid nitrogen and freeze it in a freeze dryer. After vacuum drying for 4 d, purple CQD powders were obtained, that is, stable, high-brightness and bright-colored purple CQDs.

[0052]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The fluorescence intensity | aaaaa | aaaaa |

| The fluorescence intensity | aaaaa | aaaaa |

| The fluorescence intensity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap