Method for separating and recycling metal silver and gallium

A technology for separation and recovery of metal silver, applied in the field of separation and recovery of metal silver and gallium, can solve the problems of many process steps, high acid consumption, long reaction time, etc., and achieve the effect of reducing hoarding, less acid consumption and fast speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

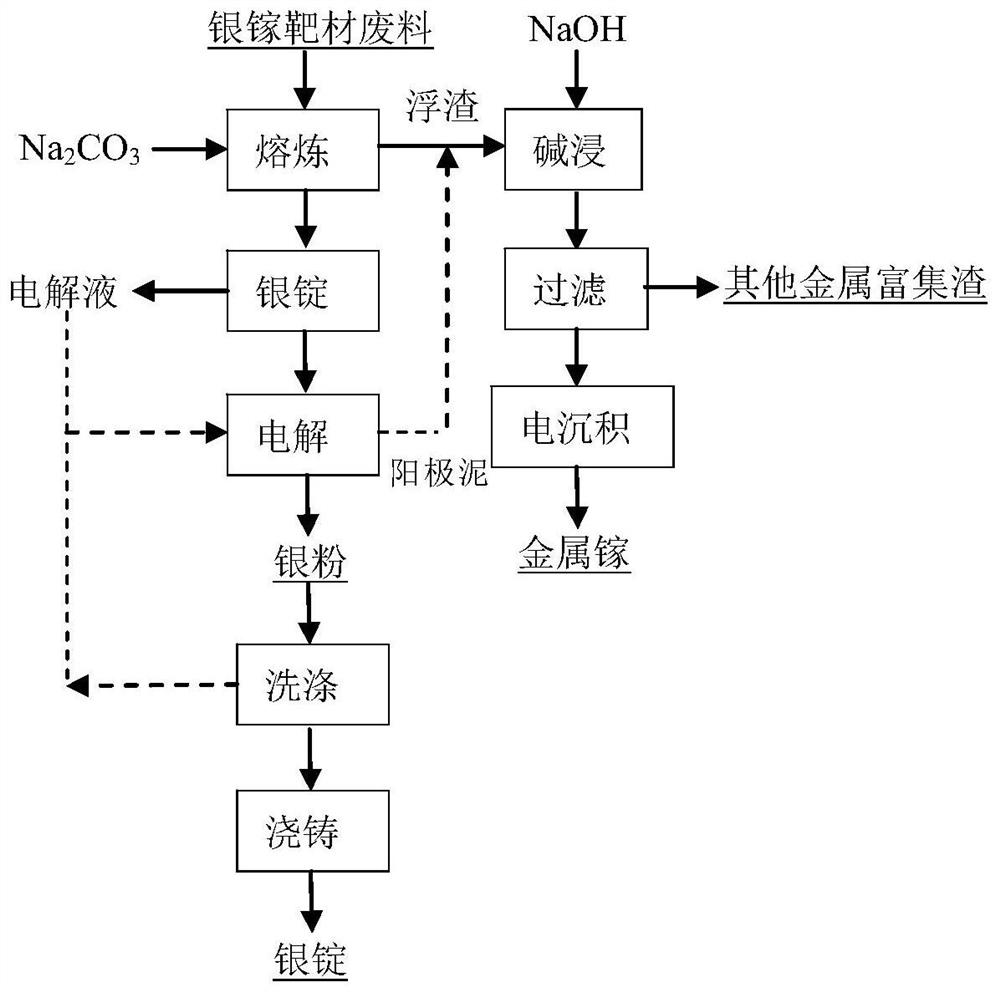

Image

Examples

Embodiment 1

[0032] Weigh 100g of silver-gallium target cutting material, then add 9g of sodium carbonate and mix it evenly, and then smelt: put the mixture in an environment of 1100°C for 4h, and at the same time, pass compressed air at a rate of 2L / min.

[0033] Recover gallium metal: Add the scum obtained after smelting to NaOH solution with a concentration of 150g / L (the mass ratio of scum to NaOH solution is 1:20) for leaching, and after leaching at 80°C for 4h, filter to obtain the leaching solution ( filtrate), and then recover metal gallium by electrolysis process: adjust the NaOH concentration in the leaching solution to 150g / L, select stainless steel for both cathode and anode, and current density 1000A / m 2 , the electrolysis temperature is 25 ℃, and the purity of 99.99% gallium metal is obtained by electrodeposition.

[0034]Metal silver recovery: metal silver is recovered through the electrolysis process, the silver ingot obtained after smelting is directly used as the anode, t...

Embodiment 2

[0036] Weigh 100g of silver-gallium target cutting material, then add 11g of sodium carbonate and 0.2g of sodium hydroxide, mix evenly, and then smelt: put the mixture in an environment of 1100°C for 6 hours, and feed oxygen at a rate of 2L / min.

[0037] Recover gallium metal: Add the scum obtained after smelting to NaOH solution with a concentration of 180g / L (the mass ratio of scum to NaOH solution is 1:15) for leaching, and after leaching at 95°C for 4h, filter to obtain the leaching solution ( filtrate), and then recover metal gallium by electrolysis process: adjust the NaOH concentration in the leaching solution to 200g / L, select stainless steel for both cathode and anode, and current density 1500A / m 2 , the electrolysis temperature is 40°C, and the purity of 99.99% gallium metal is obtained by electrodeposition.

[0038] Metal silver recovery: metal silver is recovered through the electrolysis process, and the silver ingot obtained after smelting is directly used as the ...

Embodiment 3

[0040] Weigh 100g of silver-gallium target cutting material, then add 9g of sodium carbonate and 0.45g of sodium hydroxide, mix evenly, and then smelt: put the mixture in an environment of 1200°C for 4 hours, and feed compressed air at a rate of 4L / min at the same time .

[0041] Recover gallium metal: Add the scum obtained after smelting to NaOH solution with a concentration of 200g / L (the mass ratio of scum to NaOH solution is 1:10) for leaching, and after leaching at 80°C for 6h, filter to obtain the leaching solution ( filtrate), and then recover metal gallium by electrolysis process: adjust the NaOH concentration in the leaching solution to 200g / L, select stainless steel for both cathode and anode, and current density 1800A / m 2 , the electrolysis temperature is 60°C, and the purity of gallium metal is 99.992% through electrodeposition.

[0042] Metal silver recovery: metal silver is recovered through the electrolysis process, and the silver ingot obtained after smelting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com