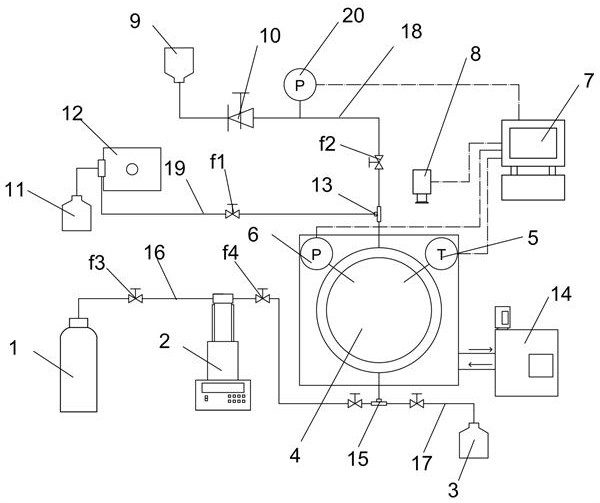

Device and method for generating microbubbles and hydrates in situ by using visual kettle

A technology of microbubbles and hydrates, applied in measuring devices, chemical method analysis, instruments, etc., can solve problems such as slow formation rate, high formation conditions, and environmental damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

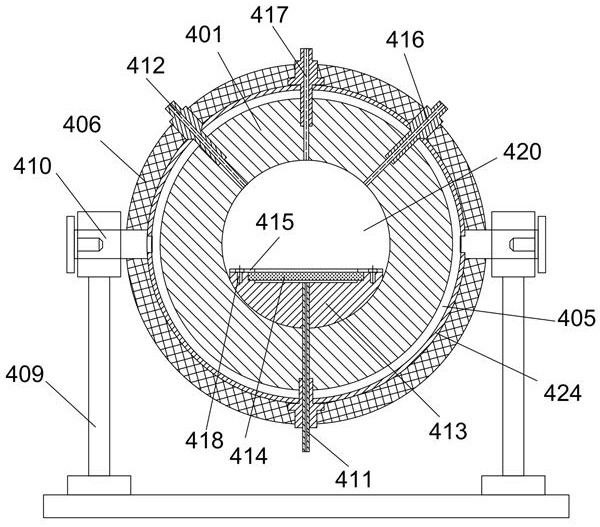

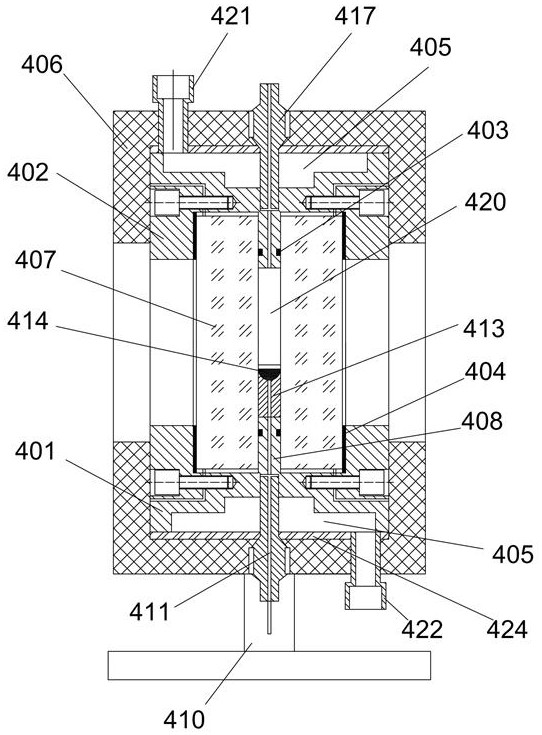

Method used

Image

Examples

Embodiment 2

[0057] Example 2 Observation of microbubbles using a porous plate visual kettle

[0058] a. Initial preparation and injection stage

[0059] a1, turn on the cooling circulation pump 14 to reduce the temperature in the kettle to the experimental temperature of 20°C and the data acquisition system 7; configure the pure water of the experimental solution to the solution bottle, and saturate the injection pump 12 with the experimental solution;

[0060] a2. Open the needle valve v1 at the liquid inlet end, and turn on the liquid injection pump 12 to inject liquid at a fixed flow rate of 9.9 mL / min to the amount of solution required for the experiment;

[0061] a3. Close the needle valve v1 at the liquid inlet end, set the value of the back pressure valve 10 to 0MPa, open the needle valve v2 at the exhaust end, and draw a vacuum through the back pressure valve 10, and set the value of the back pressure valve 10 to the required value for the experiment after exhausting Pressure val...

Embodiment 3

[0071] Example 3 Data processing of the microbubble pictures collected by the camera

[0072] a. Add image scales in batches

[0073] a1. Open the macro recorder (Marcos) of ImageJ software;

[0074] a2, open the picture with scale, use the set scale function to add scale; close the macro recorder, get the macro file with scale added;

[0075] a3. Use the batch processing function (process-batch) to import the image sequence to be processed in batches; run the macro file to obtain the image sequence with scale;

[0076] b. Automatically count the bubble area

[0077] b1. Use process-sharpen or adjust-contrast to adjust the picture to make the picture clearer;

[0078] b2. Adjust the image threshold (adjust-threshold) to binarize the image;

[0079] b3. Use process-binary-fill holes to fill the gaps in the bubbles; use process-binary-watershed to automatically segment the bubble boundaries;

[0080] b4. Automatically count the bubble area through image analysis (analyze-pa...

Embodiment 4

[0086] Example 4 Formation of Hydrate in Visible Kettle Using Porous Plate

[0087] a. Initial preparation and injection stage

[0088] a1, turn on the cooling circulation pump 14 to reduce the temperature in the kettle to the experimental temperature of 1°C and the data acquisition system 7; configure the experimental solution 500ppm SDS solution to the solution bottle, and saturate the injection pump 12 with the experimental solution;

[0089] a2. Open the needle valve v1 at the liquid inlet end, and turn on the liquid injection pump 12 to inject liquid at a fixed flow rate of 9.9 mL / min to the amount of solution required for the experiment;

[0090] a3. Close the needle valve v1 at the liquid inlet end, set the value of the back pressure valve 10 to 0MPa, open the needle valve v2 at the exhaust end, and draw a vacuum through the back pressure valve 10, and set the value of the back pressure valve 10 to the required value for the experiment after exhausting The pressure val...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com