Preparation method of multi-layer coated ternary positive electrode material

A positive electrode material and multi-layer coating technology, which is applied in the field of preparation of multi-layer coated ternary positive electrode materials, can solve the problems of unfavorable electrode performance, non-uniform coating, reducing ionic conductivity of positive electrode materials, etc., so as to improve uniformity and consistency, improve cycle performance, improve the effect of bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

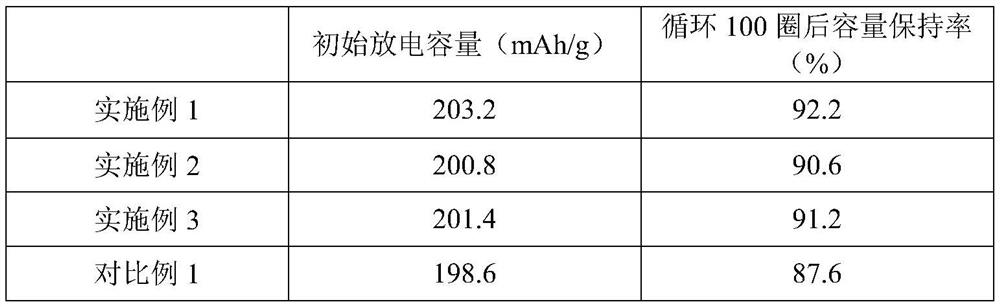

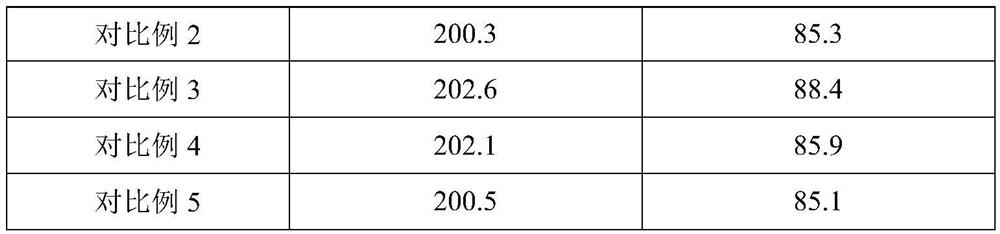

Examples

Embodiment 1

[0028]A method for preparing a multilayer coated ternary positive electrode material, comprising the steps of:

[0029] (1) Mix the NCM ternary material precursor NCM811 (Ni:Co:Mn molar ratio is 8:1:1) with lithium carbonate and zirconia, and stir evenly to obtain a powder material. The molar ratio of NCM811 to lithium carbonate is 1: 1.1, the doping amount of zirconia is 1000ppm of the mass of NCM811; the powder material is calcined once, the calcining temperature is 800°C, the calcining time is 24h, and the NCM ternary material is obtained after crushing;

[0030] (2) Mix lithium borate and lithium carbonate according to the molar ratio of B atoms and C atoms at 1:1, and sinter at 850°C for 24 hours to obtain Li 2.5 C 0.5 B 0.5 o 3 coating agent;

[0031] (3) Combining NCM ternary materials with Li 2.5 C 0.5 B 0.5 o 3 After the coating agent is mixed evenly, the secondary calcination is carried out, and the Li 2.5 C 0.5 B 0.5 o 3 The mass of the coating agent is ...

Embodiment 2

[0034] A method for preparing a multilayer coated ternary positive electrode material, comprising the steps of:

[0035] (1) Mix the NCM ternary material precursor NCM811 with lithium hydroxide and alumina, and stir evenly to obtain a powder material. The molar ratio of NCM811 to lithium hydroxide is 1:1.0, and the doping amount of alumina is 300ppm of the mass of NCM811 ;The powder material is calcined once, the calcining temperature is 700°C, the calcining time is 26h, and the NCM ternary material is obtained after crushing;

[0036] (2) Mix lithium borate and lithium carbonate uniformly at a molar ratio of B atoms to C atoms of 1:4, and sinter at 800°C for 26 hours to obtain Li 2.2 C 0.8 B 0.2 o 3 coating agent;

[0037] (3) Combining NCM ternary materials with Li 2.2 C 0.8 B 0.2 o 3 After the coating agent is mixed evenly, the secondary calcination is carried out, and the Li 2.2 C 0.8 B 0.2 o 3 The mass of the coating agent is 500ppm of the mass of the NCM tern...

Embodiment 3

[0040] A method for preparing a multilayer coated ternary positive electrode material, comprising the steps of:

[0041] (1) Mix the NCM ternary cathode material precursor NCM811 with lithium carbonate and alumina, and stir evenly to obtain a powder material. The molar ratio of NCM811 to lithium carbonate is 1:1.2, and the doping amount of zirconia is 2000ppm of the mass of NCM811; The powder material is calcined once, the calcining temperature is 900°C, the calcining time is 18h, and the NCM ternary material is obtained after crushing;

[0042] (2) Lithium borate and lithium carbonate are mixed evenly at a molar ratio of B atoms to C atoms of 2:3, and sintered at 900°C for 18 hours to obtain Li 2.4 C 0.6 B 0.4 o 3 coating agent;

[0043] (3) Combining NCM ternary materials with Li 2.4 C 0.6 B 0.4 o 3 After the coating agent is mixed evenly, the secondary calcination is carried out, and the Li 2.4 C 0.6 B 0.4 o 3 The mass of the coating agent is 2000ppm of the mass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com