Preparation and application of PtIr alloy and TiO2 coated graphene composite material

A composite material and graphene technology, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of easy attenuation and low ethanol electrooxidation efficiency, and achieve the effects of high current density, high utilization efficiency and good catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

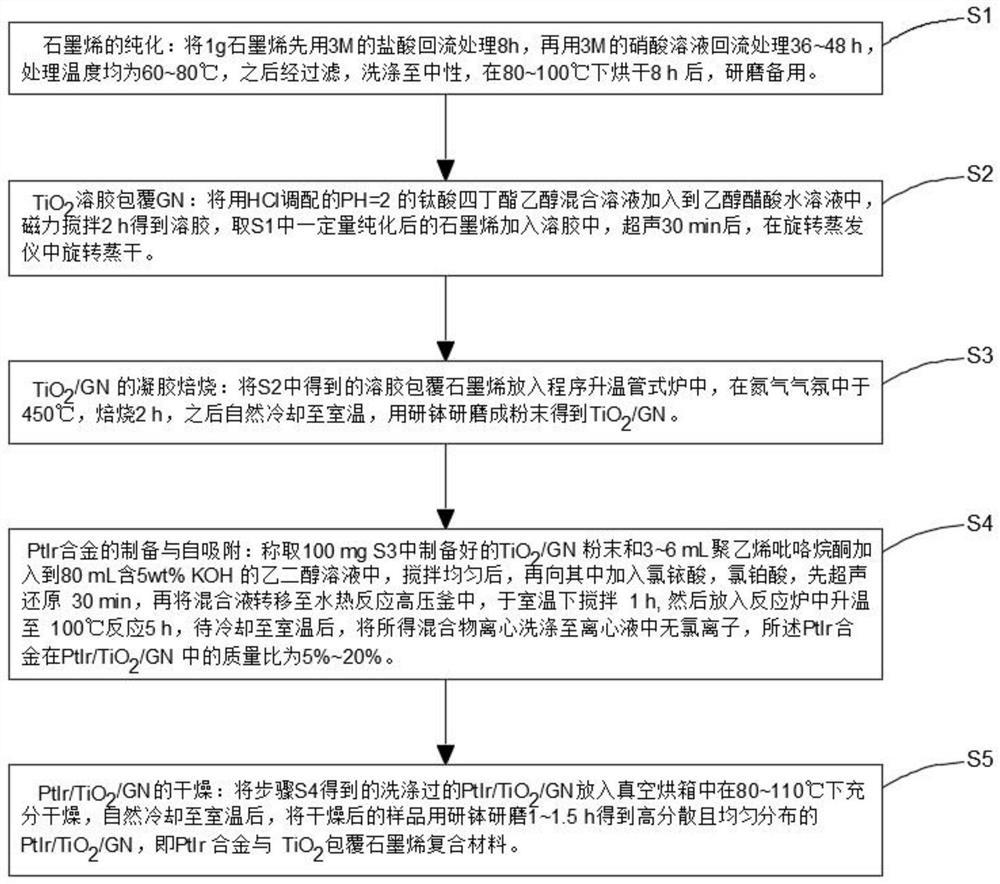

[0034] This example provides the Ir content (Pt, Ir molar ratio is 1:0.5) TiO 2 PtIr alloy and TiO with a mass content of 20% and a firing temperature of 450°C 2 A method for preparing a coated graphene composite material. At the same time, for comparison, a preparation method without adding the alloying element Ir at the same calcination temperature is also provided. It is prepared according to the following steps, such as figure 1 Shown:

[0035] S1. Purification of graphene: 1 g of graphene was first refluxed in 3M hydrochloric acid at 70°C for 8 hours, then refluxed in 3M nitric acid solution at 70°C for 40 hours, then filtered, washed until neutral, and placed in Dry in an oven at 90°C for 8 hours, grind with an agate mortar and set aside;

[0036] S2,TiO 2 Sol-coated GN: use 1M HCl to adjust the ethanol solution of tetrabutyl titanate (850 mg) to PH = 2, and slowly add it dropwise into the ethanol-acetic acid solution containing a small amount of water, and magnetic...

Embodiment 2

[0042] This example provides the Ir content (Pt, Ir molar ratio is 1:1) TiO 2 PtIr alloy and TiO with a mass content of 20% and a firing temperature of 450°C 2 A method for preparing a coated graphene composite material. The preparation steps and detection method of this example are the same as those of Example 1, but the chloroplatinic acid added in the preparation step S4 of this example is 14.8 mg, and the chloroiridic acid added is 11.6 mg.

Embodiment 3

[0044] This example provides the Ir content (Pt, Ir molar ratio is 1:2) TiO 2 PtIr alloy and TiO with a mass content of 20% and a firing temperature of 450°C 2 A method for preparing a coated graphene composite material. The preparation steps and detection method of this example are the same as those of Example 1, but the chloroplatinic acid added in the preparation step S4 of this example is 9.9 mg, and the chloroiridic acid added is 15.6 mg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com