Explosion-proof self-temperature-control heating tape and preparation method thereof

A heating belt and self-controlling temperature technology, applied in electric heating devices, ohmic resistance heating, heating element shape and other directions, can solve the problems of difficult maintenance, many power supply points, short service life, etc., and achieve reasonable structural design and formula design. Reasonable, excellent softness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

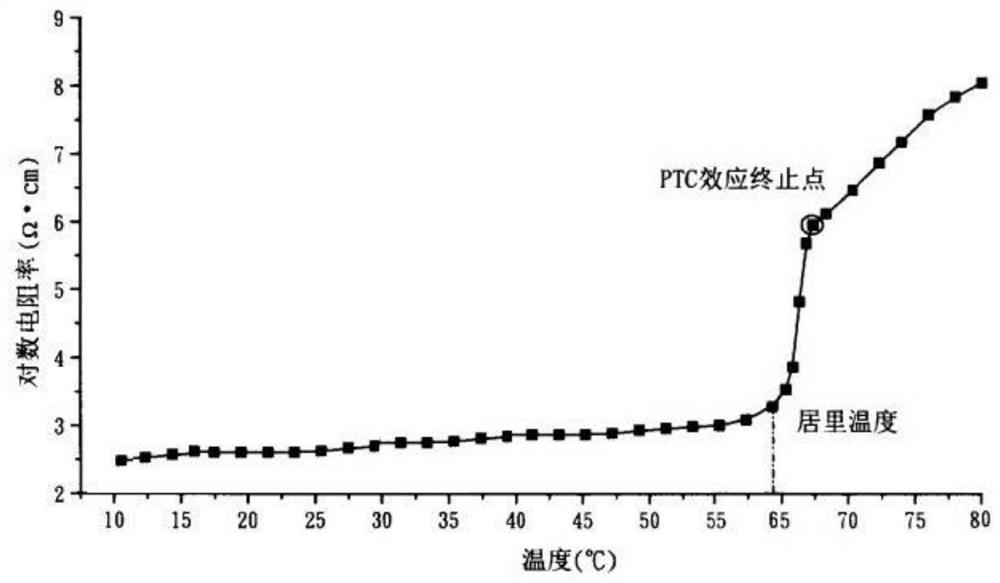

[0054] Preparation of PCT

[0055] The PTC 2 is mainly composed of the following components in parts by mass: 35 parts of n-octadecane, 16 parts of high-density polyethylene, 28 parts of acetylene carbon black, 3 parts of white carbon black, 2 parts of modified carbon nanotubes 2 parts, antioxidant 1010; According to the above formula, n-octadecane, high-density polyethylene, acetylene carbon black, silica, modified carbon nanotubes, antioxidant 1010 are prepared, and then high-density polyethylene, acetylene Carbon black, modified carbon nanotubes and white carbon black were placed in a constant temperature drying oven, and dried at 70°C for 12 hours to remove moisture; first, high-density polyethylene and antioxidant 1010 were added to the mixer for mixing, and the initial temperature of the mixer was set to 160°C, the speed is 60rpm, when the high-density polyethylene and antioxidants are completely melted, then add acetylene carbon black, white carbon black, and modified c...

Embodiment 2

[0057] Preparation of PCT

[0058]The PTC 2 is mainly composed of the following components in parts by mass: 40 parts of n-octadecane, 20 parts of high-density polyethylene, 30 parts of acetylene carbon black, 3 parts of white carbon black, 2 parts of modified carbon nanotubes 1 part, antioxidant 1010; according to the above formula, n-octadecane, high-density polyethylene, acetylene carbon black, silica, modified carbon nanotubes, antioxidant 1010 are prepared, and then high-density polyethylene, acetylene Carbon black, modified carbon nanotubes and white carbon black were placed in a constant temperature drying oven, and dried at 80°C for 12 hours to remove moisture; first, high-density polyethylene and antioxidant 1010 were added to the mixer for mixing, and the initial temperature of the mixer was set to 160°C, the speed is 60rpm, when the high-density polyethylene and antioxidants are completely melted, then add acetylene carbon black, white carbon black, and modified car...

Embodiment 3

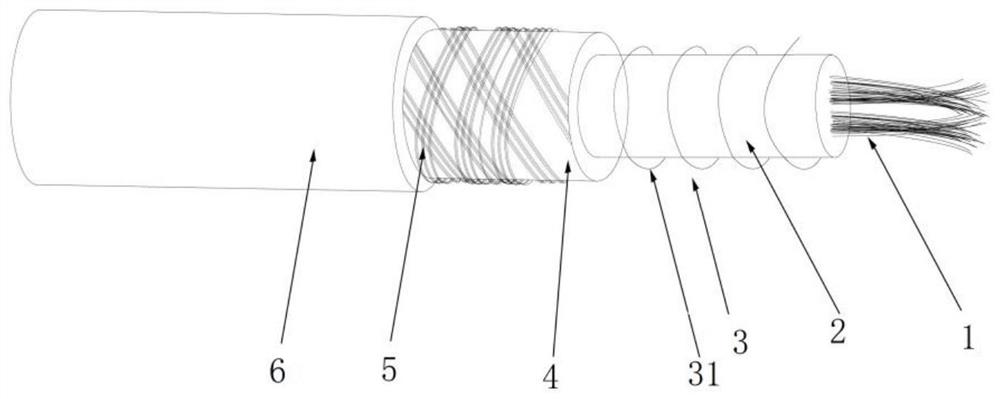

[0063] Preparation of heating wire

[0064] The heating wire (31) is braided by a number of polymerized nano-energy wires using a 1×1 four-step three-dimensional weaving method; the polymerized nano-energy wires are mainly composed of the following components in parts by mass: polyimide 60 parts, 2 parts of graphene, 3.5 parts of kaolin, 1.5 parts of antimony, 2 parts of negative ion powder, 8 parts of tourmaline, 4 parts of shale, 6 parts of ceramic balls, 3 parts of aluminum hydroxide, N,N-dimethyl ethane 5 parts of amide solvent, 2 parts of diaminodiphenyl ether.

[0065] Prepare materials according to the above formula, ultrasonically disperse graphene in N,N-dimethylacetamide solvent, then continue to stir until dissolved, add diaminodiphenyl ether several times, and pass nitrogen gas into the container for protection. Then react at a low temperature to obtain a graphene mixed solution.

[0066] Melt polyimide, kaolin, negative ion powder, tourmaline, shale, ceramic bal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com