Method for purifying sucralose-6-ethyl ester

A technology of sucralose and purification method, which is applied in the field of sugar industry, and can solve problems affecting the quality of sucralose products, production and environmental burden, and increasing the amount of solvent used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

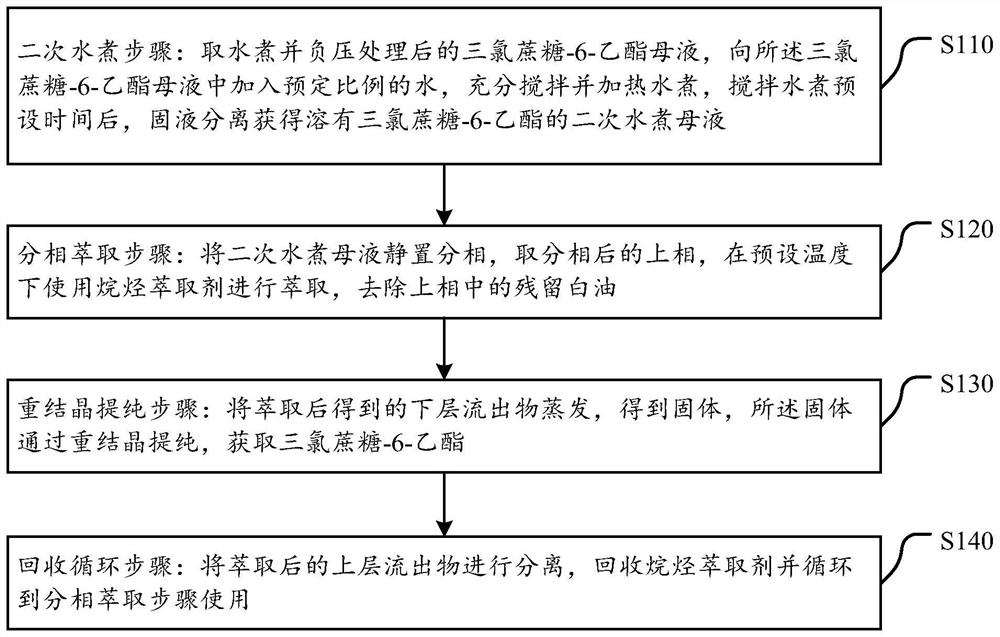

Method used

Image

Examples

Embodiment 1

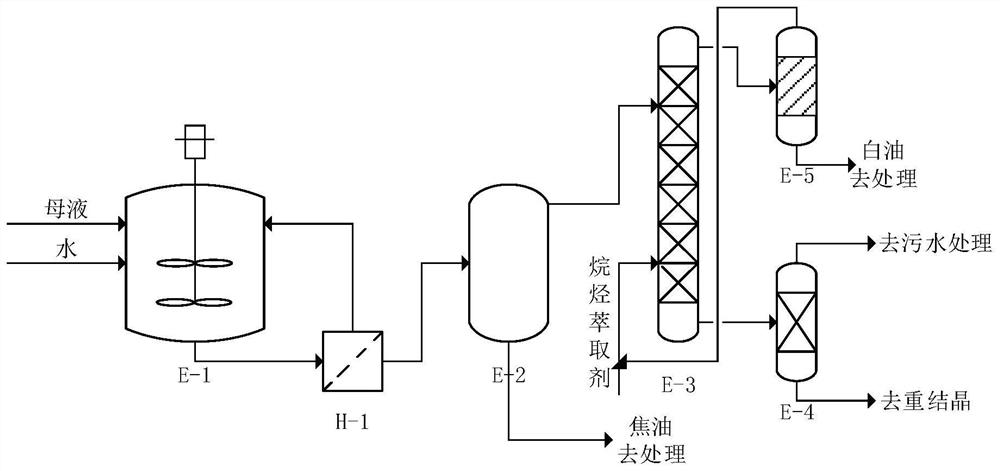

[0061] Add 1 t of sucralose-6-ethyl ester mother liquor with a water content of 30% into the mixing kettle E-1, heat and boil at 40°C, specifically, add water with a mass of 90% of the mother liquor at a stirring rate of 300r / min, Stir well. After stirring for 0.5h, it is separated by the solid-liquid separator H-1, and the solid is returned to the mixing kettle E-1, and the mother liquor enters the liquid phase separator E-2 to stand still; after the mother liquor is left standing in the liquid phase separator E-2 The brown tar in the lower phase is discharged, and the upper phase enters the upper edge of the extraction tower E-3; the extractant cyclopentane enters from the lower edge of the extraction tower E-3, the ratio of the two is 1:0.5, and the temperature is 30 ° C. Extraction, after the extraction is completed, the sucralose-6-ethyl ester aqueous solution without white oil is extracted from the bottom of the tower, and the alkane mixed liquid is extracted from the to...

Embodiment 2

[0066] Add 2t sucralose-6-ethyl ester mother liquor with a water content of 40% into mixing kettle E-1, heat and boil at 90°C, add water with 80% mother liquor mass at a stirring speed of 400r / min, and stir thoroughly. After stirring for 0.5h, it is separated by the solid-liquid separator H-1, and the solid is returned to the mixing kettle E-1, and the mother liquor enters the liquid phase separator E-2 to stand still; after the mother liquor is left standing in the liquid phase separator E-2 The brown tar in the lower phase is discharged, and the upper phase enters the upper edge of the extraction tower E-3; the extractant cyclohexane enters from the lower edge of the extraction tower, the ratio of the two is 1:0.6, and the extraction is carried out at a temperature of 25 ° C. After the extraction is completed, the tower The sucralose-6-ethyl ester aqueous solution without white oil is extracted from the bottom, and the alkane mixed liquid is extracted from the top of the towe...

Embodiment 3

[0070] Add the 3t sucralose-6-ethyl ester mother liquor with a water content of 50% into the mixing kettle E-1, heat and boil at 55°C, add water with a mass of 65% of the mother liquor at a stirring speed of 250r / min, and stir thoroughly. After stirring for 1.5h, it is separated by the solid-liquid separator H-1, and the solid is returned to the mixing kettle E-1, and the mother liquor enters the liquid phase separator E-2 to stand still; The brown tar in the lower phase is discharged, and the upper phase enters the upper edge of the extraction tower E-3; the extractant isoheptane enters from the lower edge of the extraction tower, the ratio of the two is 1:0.8, and the extraction is carried out at a temperature of 40 ° C. After the extraction is completed, the tower The sucralose-6-ethyl ester aqueous solution without white oil is extracted from the bottom, and the alkane mixed liquid is extracted from the top of the tower; the extraction liquid from the bottom of the extracti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com