Method for preparing chitosan and graft copolymer from squid fan-shaped bones

A technology of graft copolymer and chitosan, which is applied in the field of preparation of chitin polysaccharide, can solve problems such as difficult removal, inability to exert the hemostatic function of chitosan, uneven dispersion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

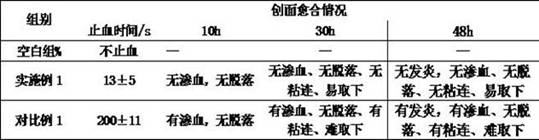

Examples

Embodiment 1

[0038] A kind of squid fan-shaped bone prepares the method for chitosan and graft copolymer, it passes through the following processing steps:

[0039] 1) Degradation of chitin

[0040] a. Take a certain amount of squid fan-shaped bone and pulverize it with an ultrafine pulverizer to obtain squid fan-shaped bone powder;

[0041] b. Add hydrogen peroxide to the squid fan-shaped bone meal obtained in step a, and rapidly heat up to 130°C hydrogen peroxide detonation point, and the treatment is completed to obtain oxidized chitosan; wherein, the concentration of the hydrogen peroxide is 68%, and the squid fan is soaked in hydrogen peroxide before heating bone meal 2.5h,

[0042] 2) Enzymolysis

[0043] Adding the oxidized chitosan obtained in step b to a composite protease, enzymatically hydrolyzing it for 10 h under the action of ultrasonic waves, centrifuging and taking the clear liquid to obtain crude liquefied chitosan; wherein, the composite protease includes alkaline prote...

Embodiment 2

[0051] A kind of squid fan-shaped bone prepares the method for chitosan and graft copolymer, it passes through the following processing steps:

[0052] 1) Degradation of chitin

[0053] a. Take a certain amount of squid fan-shaped bone and pulverize it with an ultrafine pulverizer to obtain squid fan-shaped bone powder;

[0054]b. Add hydrogen peroxide to the squid fan-shaped bone meal obtained in step a, and rapidly heat up to 100°C hydrogen peroxide detonation point, and the treatment is completed to obtain oxidized chitosan; wherein, the concentration of the hydrogen peroxide is 60%, and the squid is soaked in hydrogen peroxide before heating Fan-shaped bone meal 2h,

[0055] 2) Enzymolysis

[0056] Adding the oxidized chitosan obtained in step b to a composite protease, enzymatically hydrolyzing it for 10 h under the action of ultrasonic waves, centrifuging and taking the clear liquid to obtain crude liquefied chitosan; wherein, the composite protease includes alkaline p...

Embodiment 3

[0064] A kind of squid fan-shaped bone prepares the method for chitosan and graft copolymer, it passes through the following processing steps:

[0065] 1) Degradation of chitin

[0066] a. Take a certain amount of squid fan-shaped bone and pulverize it with an ultrafine pulverizer to obtain squid fan-shaped bone powder;

[0067] b. Add hydrogen peroxide to the squid fan-shaped bone meal obtained in step a, and rapidly heat up to 150°C hydrogen peroxide detonation point, and the treatment is completed to obtain oxidized chitosan; wherein, the concentration of the hydrogen peroxide is 70%, and the squid fan is soaked in hydrogen peroxide before heating bone meal 3h,

[0068] 2) Enzymolysis

[0069] Adding the oxidized chitosan obtained in step b to a composite protease, enzymatically hydrolyzing it for 12 hours under the action of ultrasonic waves, centrifuging and taking the clear liquid to obtain crude liquefied chitosan; wherein, the composite protease includes alkaline pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com