Breathable sealed wet-laid double-sided butyl rubber waterproof roll and waterproof system

A butyl rubber and waterproofing membrane technology, applied in the direction of roofing, adhesive, roof covering, etc., can solve the problems of easy large-area water channeling, hidden dangers, and concrete cracking on the balcony.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

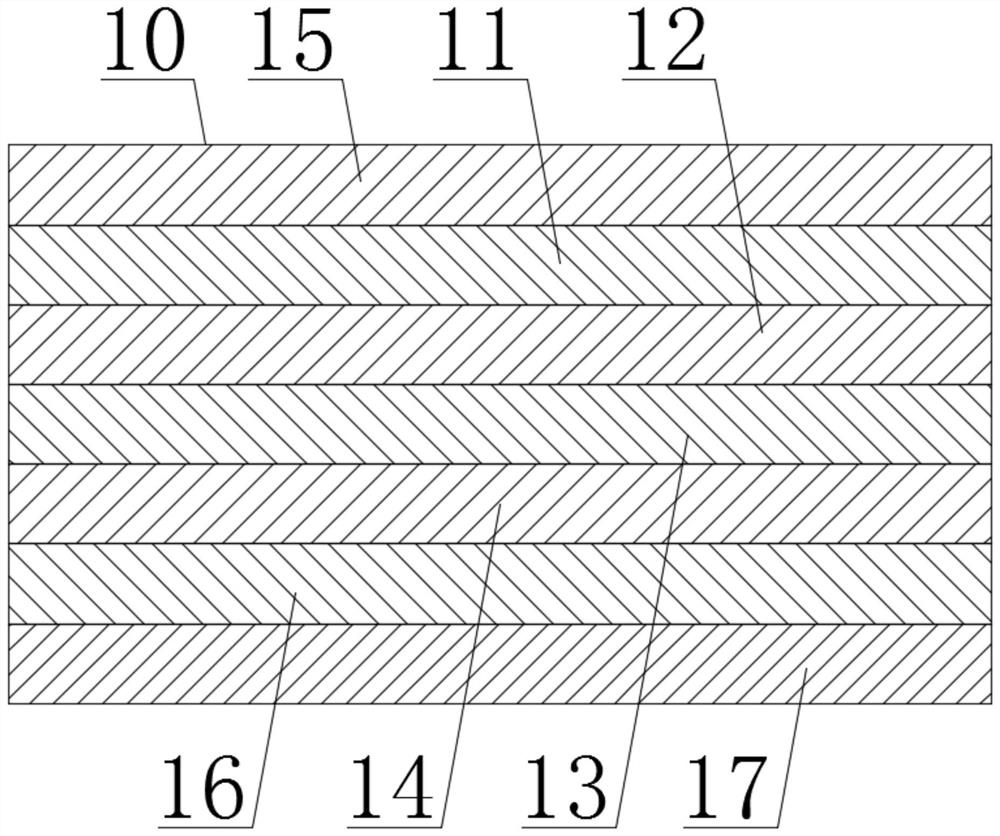

[0032] see figure 1 , the present invention provides a technical solution: a breathable and sealed wet-laid double-sided butyl rubber waterproof membrane, comprising a coil body 10, the coil body 10 comprising a first polymer homogeneous sheet 11, a metal sheet layer 12. High-strength grid cloth layer 13, second polymer homogeneous sheet 14, butyl rubber sealing adhesive surface layer 15, butyl rubber sealing adhesive inner layer 16 and airgel layer 17, the first polymer homogeneous The lower surface of the sheet 11 is bonded with a metal sheet layer 12, the lower surface of the metal sheet layer 12 is bonded with a high-strength mesh layer 13, and the lower surface of the high-strength mesh layer 13 is bonded with a second polymer homogeneous sheet 14. The lower surface of the second polymer homogeneous sheet 14 is bonded with a butyl rubber sealing adhesive inner layer 16, and the lower surface of the butyl rubber sealing adhesive inner layer 16 is bonded with an airgel laye...

Embodiment 2

[0041] This embodiment provides a gas-permeable and sealed wet-laid double-sided butyl rubber waterproof system, which includes a cement layer, and the cement layer is provided with the gas-permeable and sealed wet-laid double-sided butyl rubber waterproof roll provided by the above-mentioned embodiment 1 material.

[0042] Specifically, the preparation method of the waterproof system includes the following steps:

[0043] S1. Mix 0.1kg of hydroxyapatite, 0.5kg of EVA redispersible latex powder, 0.1kg of silane-based water repellent, 5kg of slaked lime, 0.1kg of calcium stearate, 80kg of sand, 10kg of 425# cement, and 0.5kg of osmotic crystallization , to obtain the mixture. Among them, the osmotic crystal can be used commercially available from Colo, USA; the silane-based water-repellent agent is the commercially available sea180 water-repellent agent.

[0044] S2. Mix the above mixture with water at a mass ratio of 1:0.3 to obtain cement slurry.

[0045] S3. Spread the ce...

Embodiment 3

[0047] This embodiment provides a gas-permeable and sealed wet-laid double-sided butyl rubber waterproof system, which includes a cement layer, and the cement layer is provided with the gas-permeable and sealed wet-laid double-sided butyl rubber waterproof roll provided by the above-mentioned embodiment 1 material.

[0048] Specifically, the preparation method of the waterproof system includes the following steps:

[0049] S1. Mix 2 kg of hydroxyapatite, 2 kg of EVA redispersible latex powder, 1 kg of silane-based water repellent, 15 kg of slaked lime, 1 kg of calcium stearate, 60 kg of sand, 20 kg of 425# cement, and 1.5 kg of osmotic crystallization to obtain a mixture . Among them, the osmotic crystal can be used commercially available from Colo, USA; the silane-based water-repellent agent is the commercially available sea180 water-repellent agent.

[0050] S2. Mix the above mixture with water at a mass ratio of 1:0.5 to obtain cement slurry.

[0051] S3. Spread the ceme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com