A UV-activated two-component superhydrophobic polyurethane ring adhesive

A two-component polyurethane and polyurethane prepolymer technology, which is applied in the field of wrapping adhesive, can solve the problems of affecting the performance of the optical fiber ring, the uniformity of the wrapping adhesive being deteriorated, and the accuracy of the optical fiber ring. Ring side cracking, good glue uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

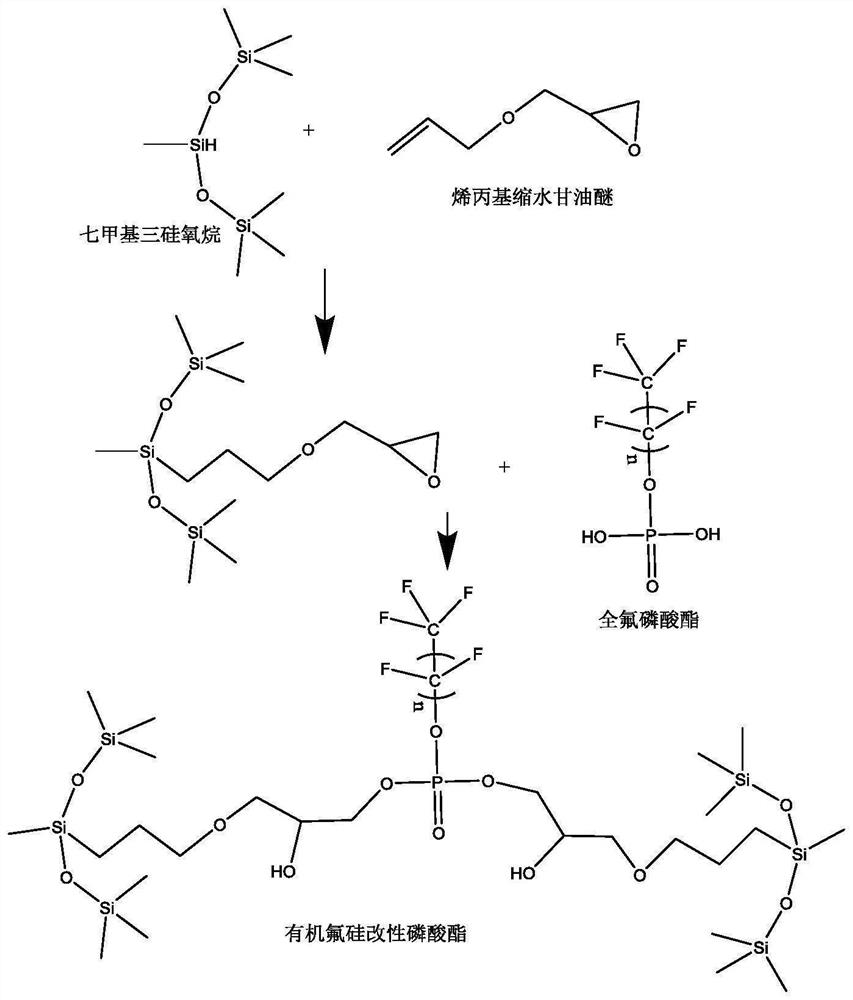

Method used

Image

Examples

Embodiment 1

[0048] A UV-activated two-component polyurethane ring adhesive, including two components AB,

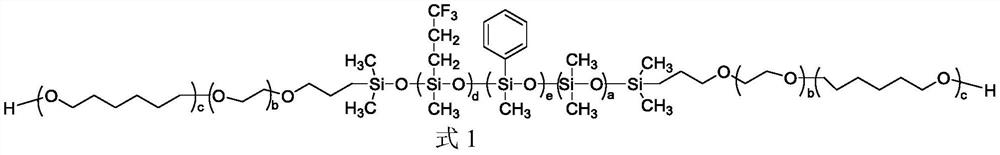

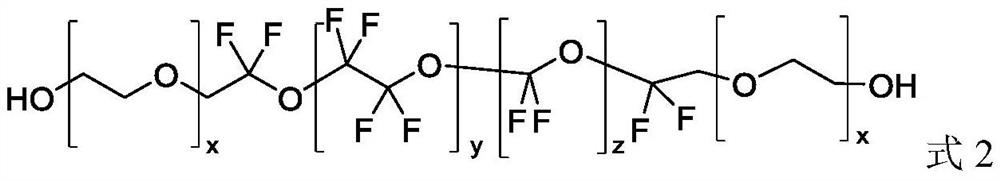

[0049] Wherein, the A component is a hydrophobic polyurethane prepolymer, and the preparation method is as follows: 205.055g of 1H,1H,11H,11H-perfluoro-3,6,9-trioxyundecane-1,11-diol (0.5 mol), 733.5g of hydroxypropyl-terminated organofluorine-modified siloxane (SF-001) (0.5mol) was added to the reactor with stirring and heated to 80-90°C, and the vacuum degree was kept at 0.09MPa-0.1MPa while stirring. Vacuum dehydration for 3 hours in the state of 100 °C, then cooled to below 60 °C, added 444.48 g of isophorone diisocyanate (IPDI) (2mol), maintained at 80-83 °C for 3 h, and after the reaction of the hydroxyl group was completed, the reaction was terminated to obtain the obtained Said hydrophobic polyurethane prepolymer S-1 has an NCO equivalent of 691.5 and an NCO content of 6.073%.

[0050] Component B is prepared by mixing the following components by mass percentage: hydroxyprop...

Embodiment 2

[0053] A UV-activated two-component polyurethane ring adhesive, including two components AB,

[0054] Wherein, component A is a hydrophobic polyurethane prepolymer, and the preparation method is as follows: add 1467g of hydroxypropyl-terminated organofluorine modified siloxane (SF-001) (1mol) into a reactor with stirring and heat to 90-95 ℃, keep the vacuum degree of 0.09MPa-0.1MPa, vacuum dehydration for 3 hours under stirring, then cool down to below 60℃, add 524.6g 4,4-diisocyanate dicyclohexylmethane (HMDI) (2mol) and maintain 85- The reaction was carried out at 88° C. for 4 hours. After the hydroxyl group reaction was completed, the reaction was terminated to obtain the hydrophobic polyurethane prepolymer S-2 with an NCO equivalent of 995.8 and an NCO content of 4.22%.

[0055] Component B is composed of the following components by mass percentage: hydroxypropyl end-capped organofluorine-modified siloxane (SF-001) 58.5%, polycaprolactone-modified organofluorine-modified p...

Embodiment 3

[0058] A UV-activated two-component polyurethane ring adhesive, including two components AB,

[0059] Wherein, component A is a hydrophobic polyurethane prepolymer, and the preparation method is as follows: 1450 g of polycaprolactone-modified organofluorine-modified phenylsiloxane (SF-002) (0.5 mol) is added to a reactor with stirring Heating to 95-100℃, keeping the vacuum degree of 0.09MPa-0.1MPa, vacuum dehydration for 3 hours under stirring, then cooling to below 60℃, adding 168.19g hexamethylene diisocyanate (HDI) (1mol) and maintaining 75 -80°C for 6 hours, and after the hydroxyl group reaction is complete, the reaction is terminated to obtain the hydrophobic polyurethane prepolymer S-3 with an NCO equivalent of 1618.19 and an NCO content of 2.59%.

[0060] Component B is prepared by mixing the following components according to mass percentage: hydroxypropyl terminated organofluorine modified siloxane (SF-001) 67.3%, 1H, 1H, 11H, 11H-perfluoro-3,6, 9-Trioxyundecane-1,11-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com