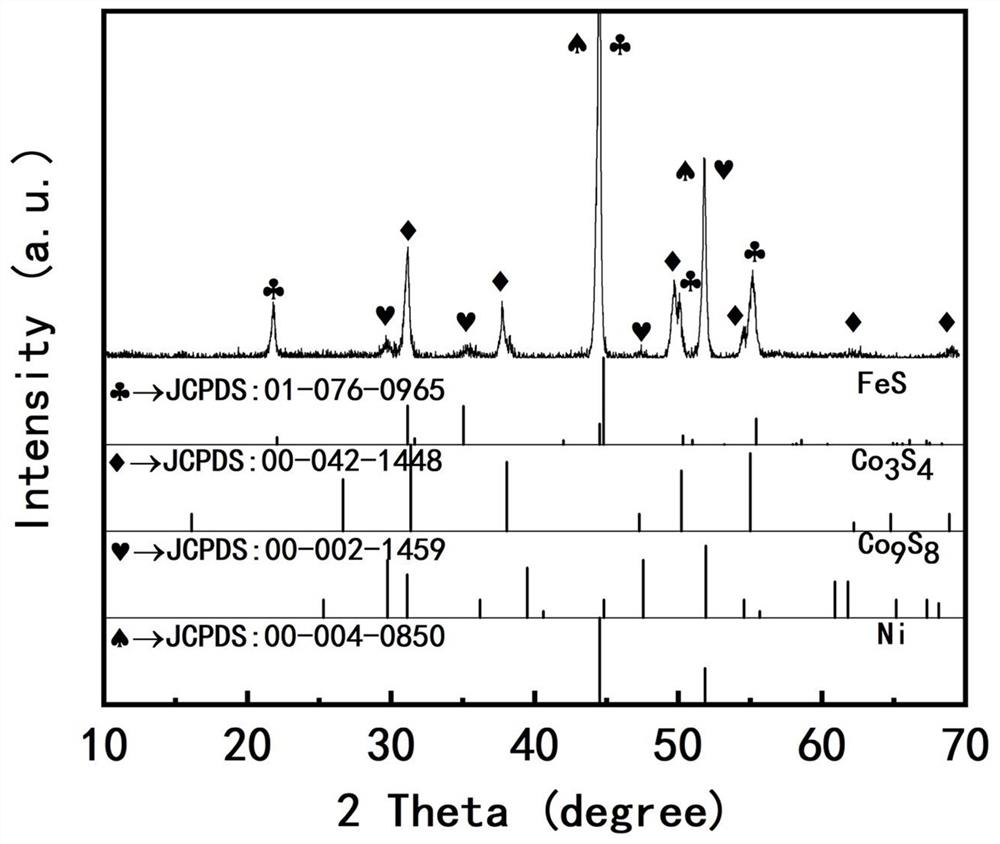

Preparation method and application of P-doped FeS/Co3S4/Co9S8 composite material

A composite material, co3s4 technology, applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, etc., can solve the problems of low working voltage and low capacity of asymmetric supercapacitors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

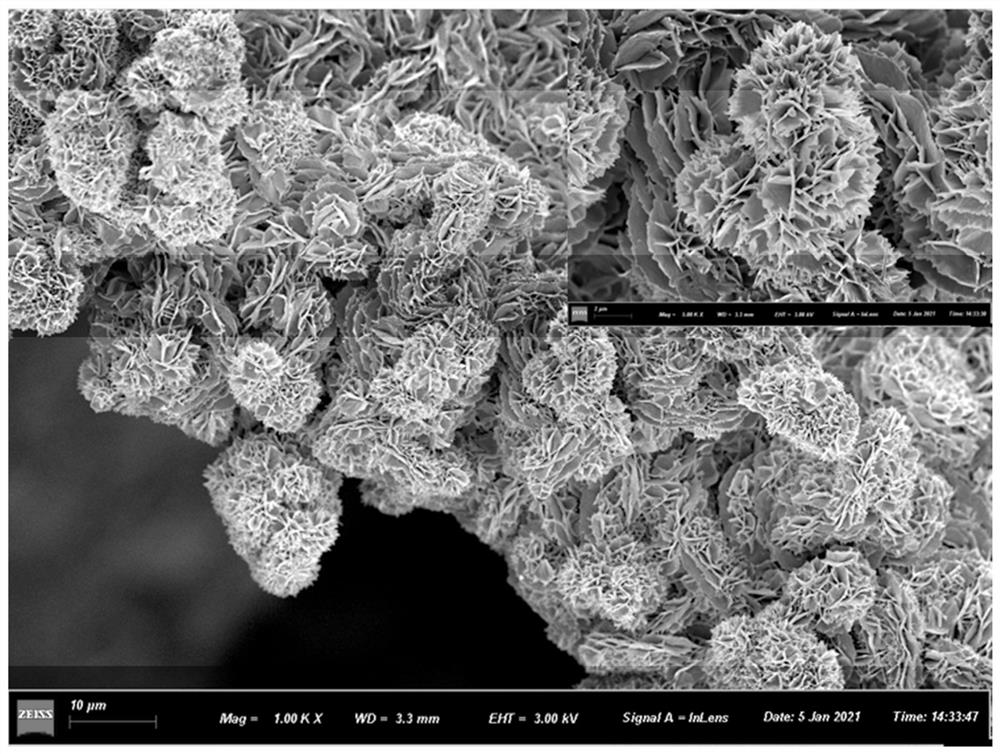

[0034] Step 1: Weigh 0.7mmol ferric nitrate and 0.7mmol cobalt nitrate and dissolve them in 35mL deionized water, stir for 10min to obtain a transparent solution, add 3.5mmol urea and 0.028mol ammonium fluoride under magnetic stirring to make it dissolve in transparent solution, put the resulting solution into a 50mL polytetrafluoroethylene liner, put a piece of 2cm×3cm foam nickel, then put the liner into a stainless steel hydrothermal kettle and seal it well, and put it in a constant temperature drying oven at 120°C. Keep warm for 8h, and cool down to room temperature naturally after the reaction is completed.

[0035] Step 2: Take out the sample, ultrasonically clean it once in deionized water and absolute ethanol, each time for 10 minutes, and dry it under natural conditions after cleaning.

[0036] Step 3: Weigh 0.0175mol sodium sulfide and dissolve it in 35mL deionized water. After fully dissolving, put it into the PTFE lining, put the sample obtained in the second step,...

Embodiment 2

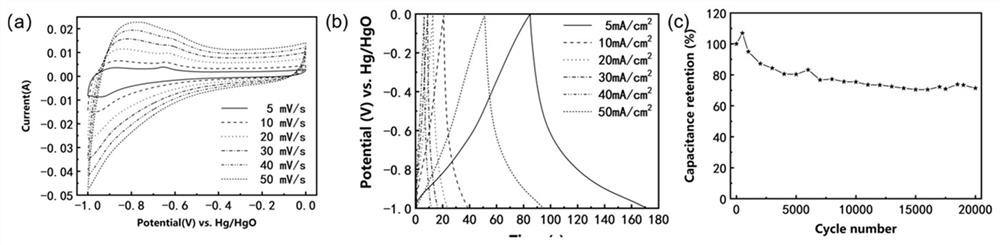

[0041] Compared with embodiment 1, embodiment 2 uses 0.0014mol ammonium fluoride, and all the other are the same as embodiment 1. attached Figure 8 It is the graph of the electrochemical performance of the sample. In the potential range of -1 to 0V, the capacity is 202.72F / g, and the capacity retention rate after 3000 cycles is only 43.76%.

Embodiment 3

[0043] Compared with embodiment 1, embodiment 3 uses 0.014mol ammonium fluoride, and all the other are the same as embodiment 1. attached Figure 10 It is the graph of the electrochemical performance of the sample. In the potential range of -1 to 0V, the capacity is 287.67F / g, and the capacity retention rate after 3000 cycles is only 17.02%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com