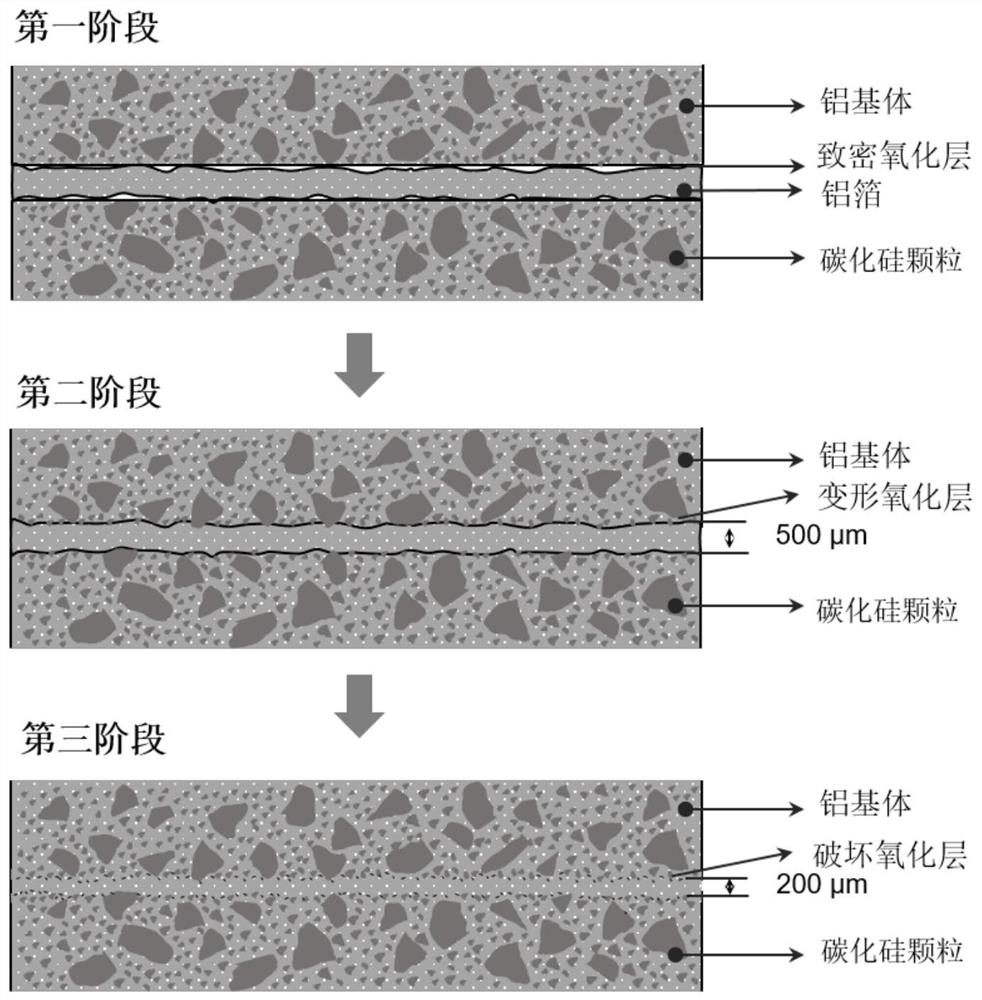

A welding method of 65% silicon carbide particle reinforced aluminum matrix composites with pure al as the intermediate material layer

A technology of silicon carbide particles and intermediate materials, applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problems of large specific gravity, failure to meet performance requirements, low thermal conductivity, etc., and achieve hardness and tensile strength improvement , Facilitate diffusion welding, good effect of welding seam formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Step 1. Surface pretreatment: use wire electric discharge cutting to process the base material to be welded into a block of 10*30*3mm, mechanically polish the base material to be welded with 1000-mesh sandpaper, and coat the surface of the aluminum-based base material The oxide film is broken;

[0059] Step 2. Surface cleaning: immerse the base metal to be welded in acetone to remove grease on the surface of the aluminum-based base metal, immerse in 10% NaOH for 5 minutes, and immerse in 10% HNO 3 5 minutes, use chemical reaction to remove residual oxide film;

[0060] Step 3. After the cleaning is completed, ultrasonically clean with deionized water to clean the surface acid, alkali and SiC particles;

[0061] Step 4. Apply ethylene glycol dibutyl ether evenly on the surface of the base metal to be welded to prevent the surface of the aluminum alloy from being oxidized again;

[0062] Step five, the assembly step before welding, the intermediate material layer is sa...

Embodiment 2

[0066] The difference from Example 1 is that in step six, the temperature is finally raised to 520°C.

Embodiment 3

[0068] The difference from Example 1 is that in step six, the temperature is finally raised to 540°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com