Welding method of 65% silicon carbide particle reinforced aluminum matrix composite adopting pure Al as intermediate material layer

A technology of silicon carbide particles and intermediate materials, applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve problems such as large specific gravity, low thermal conductivity, and failure to meet performance requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

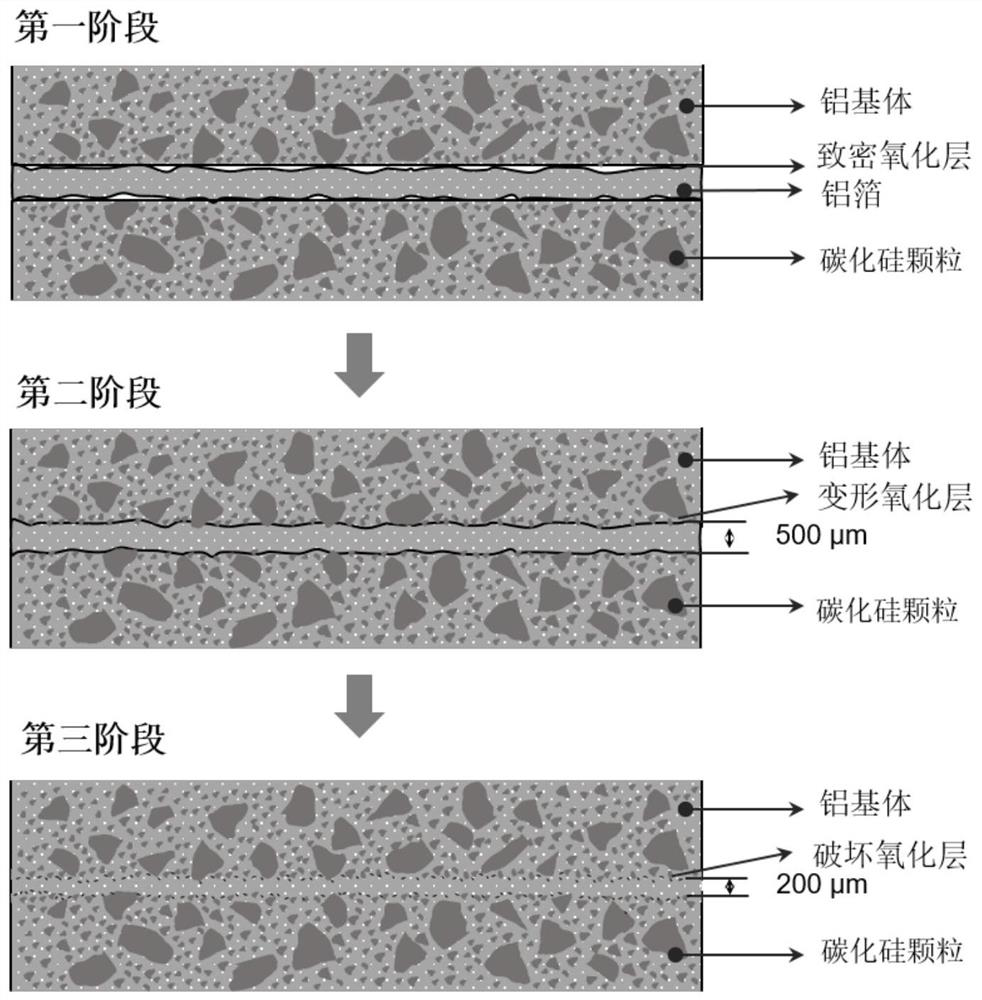

Method used

Image

Examples

Embodiment 1

[0058] Step 1. Surface pretreatment: use wire electric discharge cutting to process the base material to be welded into a block of 10*30*3mm, mechanically polish the base material to be welded with 1000-mesh sandpaper, and coat the surface of the aluminum-based base material The oxide film is broken;

[0059] Step 2. Surface cleaning: immerse the base metal to be welded in acetone to remove grease on the surface of the aluminum-based base metal, immerse in 10% NaOH for 5 minutes, and immerse in 10% HNO 3 5 minutes, use chemical reaction to remove residual oxide film;

[0060] Step 3. After the cleaning is completed, ultrasonically clean with deionized water to clean the surface acid, alkali and SiC particles;

[0061] Step 4. Apply ethylene glycol dibutyl ether evenly on the surface of the base metal to be welded to prevent the surface of the aluminum alloy from being oxidized again;

[0062] Step five, the assembly step before welding, the intermediate material layer is sa...

Embodiment 2

[0066] The difference from Example 1 is that in step six, the temperature is finally raised to 520°C.

Embodiment 3

[0068] The difference from Example 1 is that in step six, the temperature is finally raised to 540°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com