Enzyme manufacture method, and enzyme

A manufacturing method and polymer technology, applied in biochemical equipment and methods, enzymes, hydrolytic enzymes, etc., can solve problems such as enzyme inactivation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

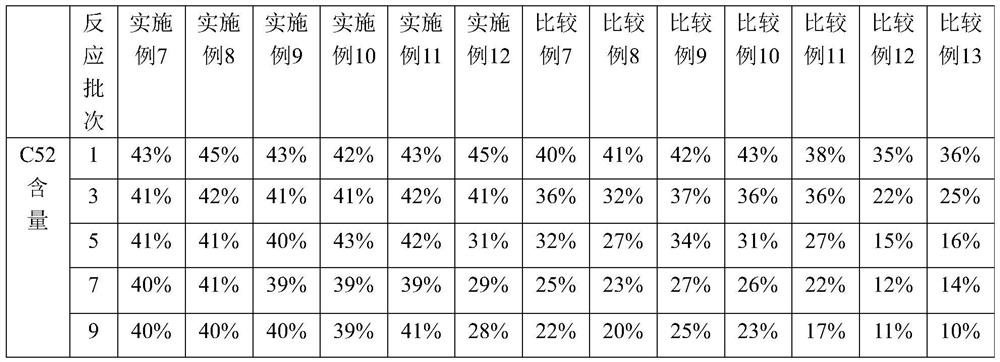

Examples

Embodiment 1

[0099] Put 10g of immobilized lipase Lipozyme TL IM granzyme (manufactured by Novozymes) and 35g AmberliteXAD16N resin (manufactured by Rohm and Haas) into a 250mL Erlenmeyer flask, then add 60mL of 0.05mol / L glycine buffer at pH8.0 solution, followed by adding 7g of glucose, and placed in an air bath shaker at 20°C for 10h. Then, the obtained mixture was put into a centrifuge and centrifuged at a centrifugal force of 8000 g for 3 min, the resin layer was taken out, and placed in a fume hood at room temperature for drying. After 24 hours, the moisture content was determined to be 8%.

Embodiment 2

[0101] Put 10 g of immobilized lipase Lipozyme TL IM granzyme (manufactured by Novozymes) and 20 g of Amberchrom CG1000 resin (manufactured by Rohm and Haas) into a 250 mL Erlenmeyer flask, then add 40 mL of 0.1 mol / L glycine buffer at pH 6.5 liquid, followed by adding 0.4g of maltose, placed in an air-bath shaker at 20°C and shaken for 10h. Then, the resulting mixture was put into a centrifuge and centrifuged at a centrifugal force of 6000 g for 3 min, the resin layer was taken out, and placed in a fume hood at room temperature for drying. After 24 hours, the moisture content was determined to be 7%.

Embodiment 3

[0103] 10g of immobilized lipase Lipozyme TL IM granzyme (manufactured by Novozymes) was cut into powder in a shearing machine, and then dropped into a 250mL conical flask with 90g NK110 resin (manufactured by Tianjin Nankai Hecheng Technology Co., Ltd.), Add 50 mL of 0.02 mol / L glycine buffer solution with pH 7.0, followed by 5 g of galactose, and shake in an air-bath shaker at 20°C for 10 h. Then, the resulting mixture was put into a centrifuge and centrifuged at a centrifugal force of 6000 g for 3 min, the resin layer was taken out, and placed in a fume hood at room temperature for drying. After 24 hours, the moisture content was determined to be 7%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com