Th-MOF loaded Cu-based single-site catalytic material as well as preparation method and application thereof

A catalytic material and single-site technology, applied in electrolytic components, electrodes, electrolytic processes, etc., can solve the problem of low catalytic activity of catalysts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1: The preparation method of a Th-MOF supported Cu-based single-site catalytic material of this embodiment is carried out according to the following steps:

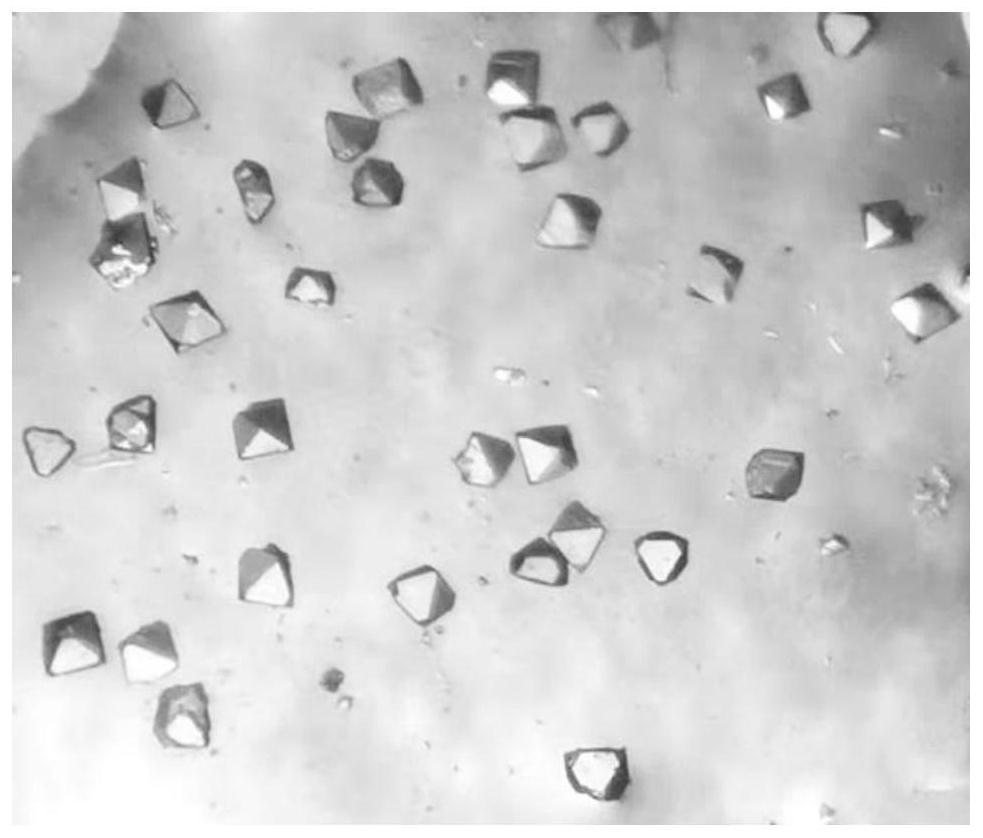

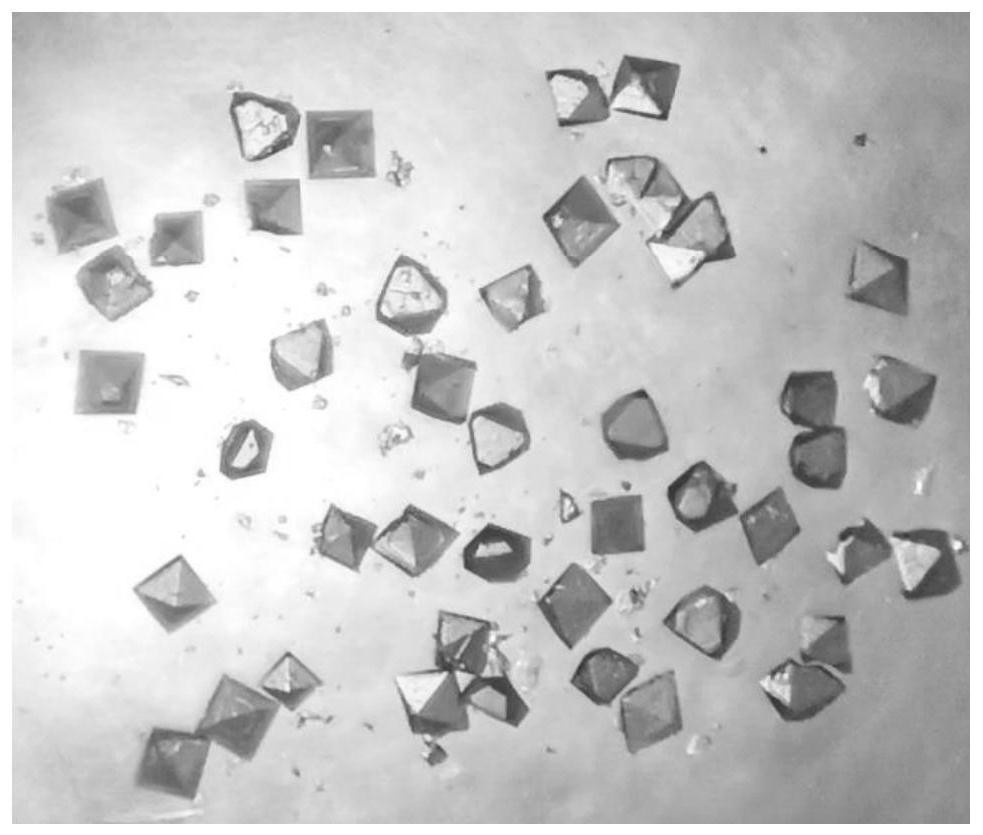

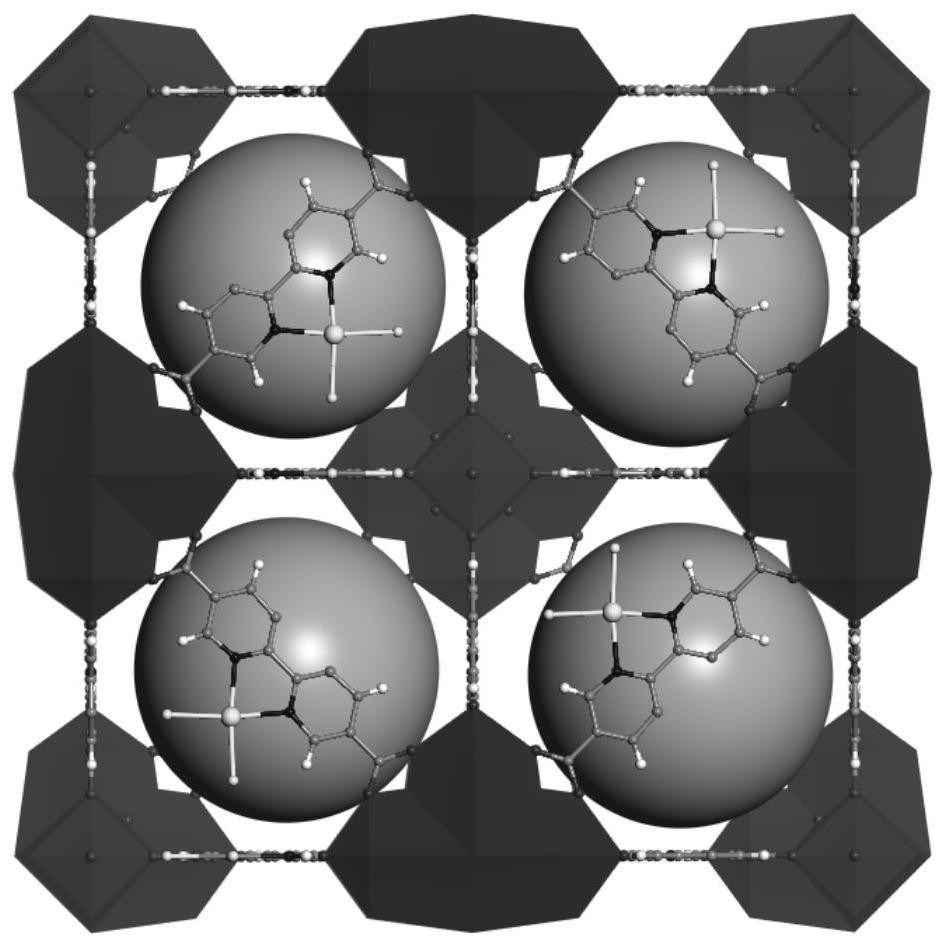

[0030] Step 1. Preparation of Th-MOF material: Dissolve 1 mmol of thorium nitrate hexahydrate and 1 mmol of 2,2'-bipyridine-5,5'-dicarboxylic acid in 3 mL of N,N'-dimethylformamide solution, then add 1mmol of nitric acid, stir evenly, transfer to a polytetrafluoroethylene lining, seal it and put it into a high-pressure reactor, heat it to 110°C at a heating rate of 1°C / min in a muffle furnace and keep the temperature constant Reacted for 3 days, centrifuged after the reaction, washed with methanol, and vacuum-dried at a temperature of 70 ° C to obtain a colorless octahedral crystal Th-BPYDC (see figure 1 ), namely Th-MOF material;

[0031] Step 2, preparing a precursor solution containing copper ions: dissolving 0.5 g of copper chloride in 5 mL of acetonitrile solution to prepare a precursor solution co...

Embodiment 2

[0035] Example 2: The Th-MOF-loaded Cu-based single-site catalytic material (Cu@Th-BPYDC) prepared in Example 1 was used in the electroreduction of NO 3 - Application in synthetic ammonia.

[0036]Electroreduction of NO with Cu@Th-BPYDC prepared in Example 1 3 - Synthetic ammonia, the result is as Figure 4-Figure 8 shown.

[0037] Depend on Figure 4 It can be seen that the Cu@Th-BPYDC of Example 1 has excellent electroreduction of NO 3 - Ammonia performance with current density up to 80.7mA cm at -0.1Vvs RHE potential -2 , much better than Cu-free Th-BPYDC. With the increase of cathode potential, the rate of ammonia formation gradually increased ( Figure 5 ), but the Faradaic efficiency presents a volcanic trend of first increasing and then decreasing ( Figure 6 ), the ammonia formation rate and Faradaic efficiency are as high as 225.3 μmol h at the optimal voltage -0.1 V vs RHE -1 cm -2 and 92.5%. The Cu@Th-BPYDC single-site catalyst has excellent stability, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com