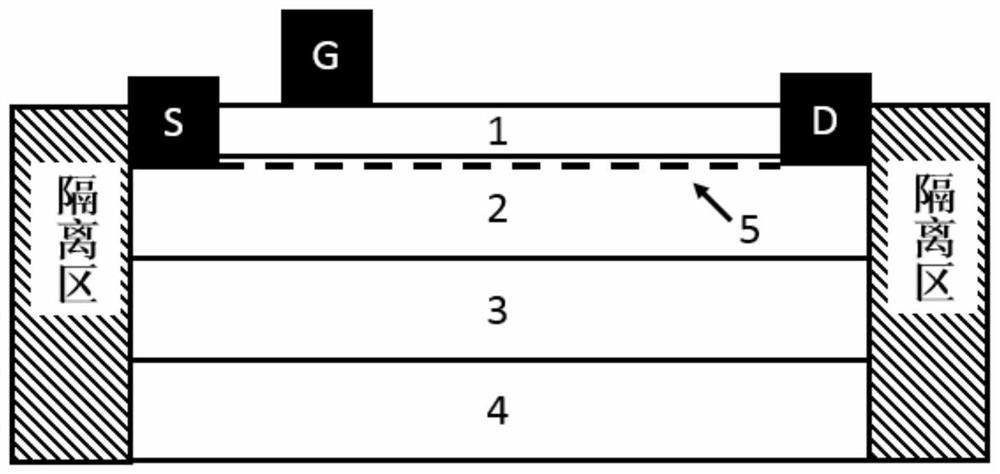

hemt device and its self-isolation method and manufacturing method

A technology of devices and conditions, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve problems affecting device dynamic characteristics, deep energy level defects, device surface leakage, etc., to avoid collapse effect and reduce process complexity Degree and manufacturing cost, the effect of increasing the breakdown voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

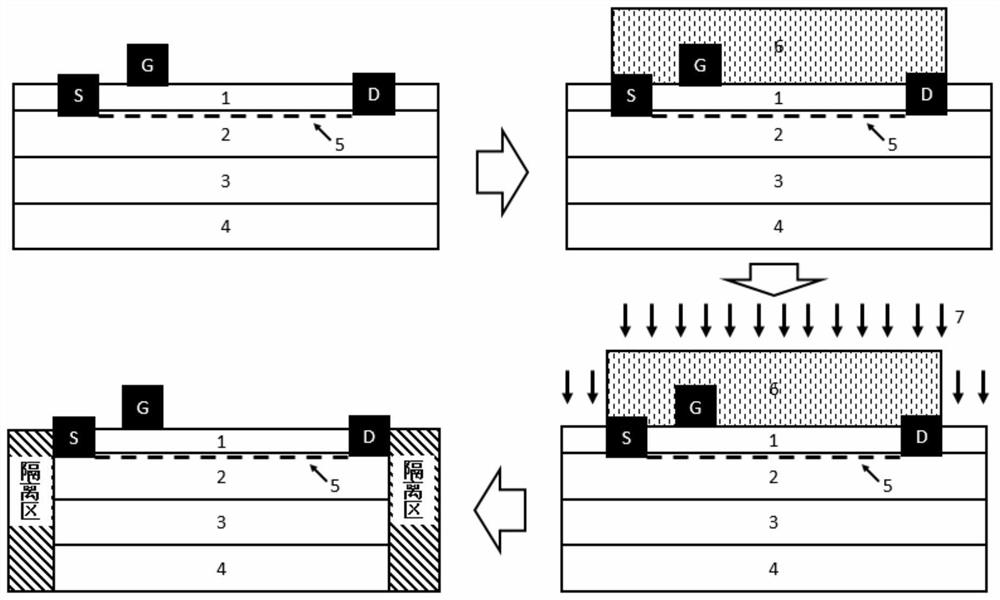

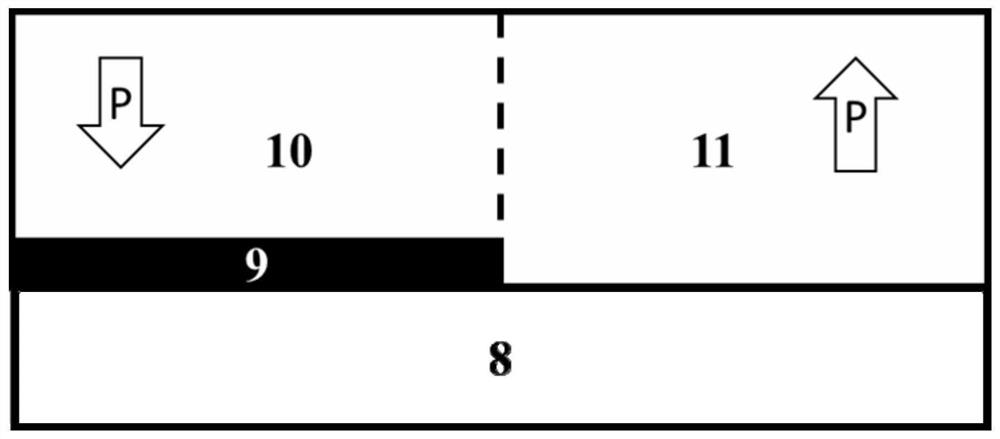

Embodiment 1

[0092] 4) A SiN surface passivation layer is deposited on the metal polar region, and a gate electrode is deposited on the SiN surface passivation layer.

Embodiment 2

[0099] 4) A SiN surface passivation layer is deposited in the nitrogen polar region, and a gate electrode is deposited on the SiN surface passivation layer.

[0103]

Embodiment 3

[0109] 4) depositing a SiN surface passivation layer on the metal polar region, and depositing a gate electrode on the SiN surface passivation layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com