Nano quantum dot low-temperature synthesis device and method and application thereof in sulfur indium silver quantum dot synthesis

A technology of nano-quantum dots and synthesis methods, applied in the synthesis of AgInS2 quantum dots, in the field of low-temperature synthesis devices for nano-quantum dots, which can solve the problems of low efficiency in synthesizing semiconductor nano-quantum dots, increasing the difficulty of device preparation, and finding strengthening means, etc. problem, achieve high yield and enhanced effect, improve synthesis efficiency, and reproducible effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

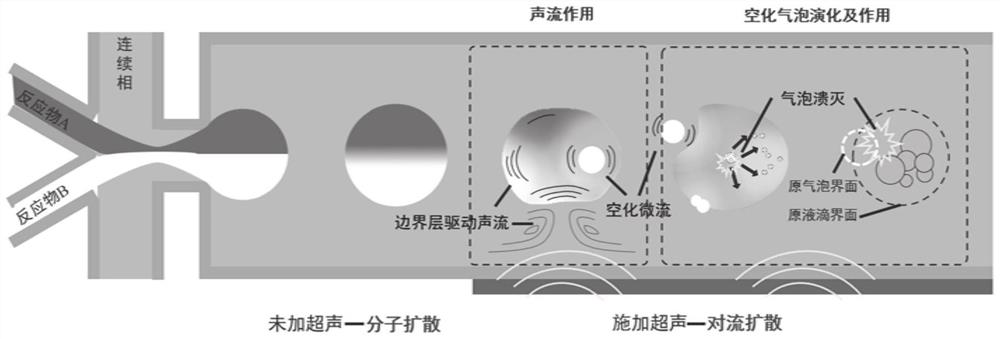

[0043] The present disclosure or a some embodiments, there is provided a quantum dot nano-temperature synthesis method, comprising the steps of: in the synthesis reactor droplet, by ultrasonic cavitation of the fluid droplet reactor turbulent motion state was state, ultrasonic cavitation bubbles and causes the generated droplet sliced until the mean droplet size down to the nanometer scale.

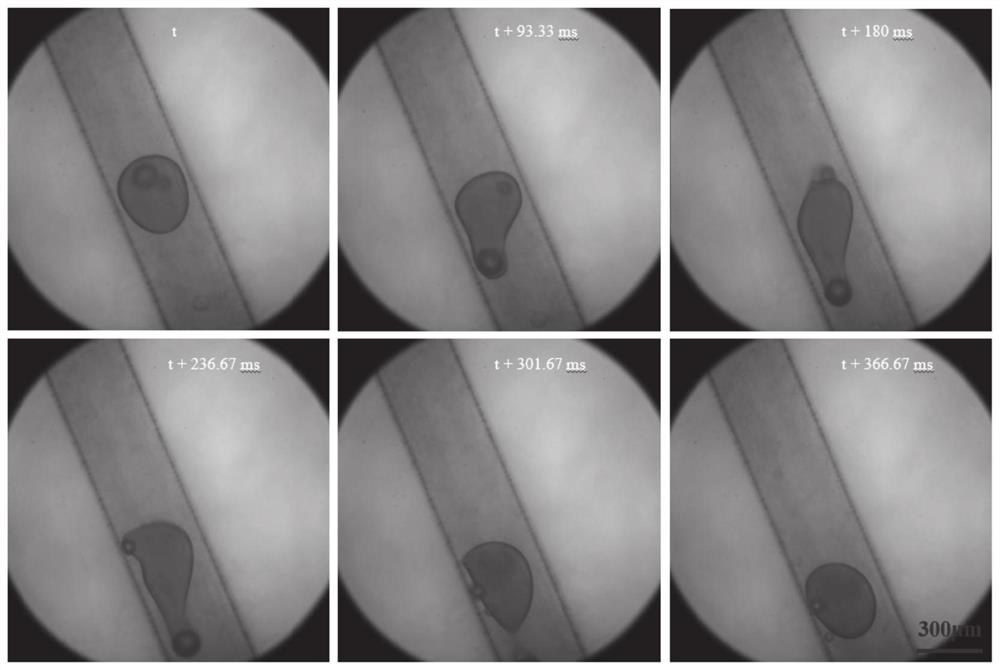

[0044] From image 3, The present disclosure of the quantum dot nano-temperature synthesis method, a droplet is sliced turbulent flow is mainly due to the bubbles generated due to the cavitation, and therefore, in theory, as long as a droplet to ensure turbulent flow ultrasonic cavitation bubble generation scheme, can achieve quantum dot nano-temperature synthesis, it is possible to achieve microdroplets interrupter, any ultrasonic cavitation droplet path of the reactor, and the binding mode of the ultrasound transducer, the present disclosure shall be protected content.

[0045] Preferabl...

Embodiment 1

[0071] The present embodiment provides a AgInS 2 QDs temperature synthesis method, comprising the steps of:

[0072] Step (1): Configure QDs synthesized precursor reagent

[0073] To AgInS 2 QDs synthesized based systems, ultrasonic enhanced low-temperature synthesis set forth. Select AgNO 3 , In (NO 3 ) 3 And Na 2 S as a precursor, an appropriate amount weighed and dissolved in deionized water, stirring to complete dissolution, the pH adjusted by NaOH solution. After the configuration of the syringe are injected.

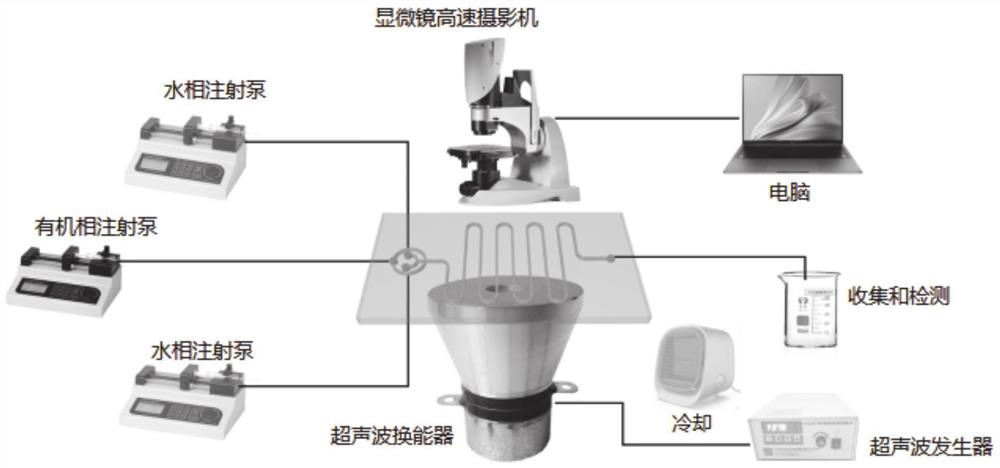

[0074] Step (2): Ultrasonic droplet structures reactor system

[0075] Objective droplet build platform is that the reactor to complete the droplet generation, effect, observing systems. Inlet were introduced into the continuous phase (organic phase) and a dispersed phase (aqueous phase), by microinjection pump at a constant speed continuously pumped into two phases, a dispersed phase is the continuous phase form a continuous pinch off microdroplets continuously within...

Embodiment 2

[0084] The present embodiment provides a AgInS 2 QDs temperature synthesis method, the difference of Example 1 wherein: step (3), the ultrasonic parameter is 25w.

[0085] From Figure 5 Run, Example 2 was shorter wavelength emission QDs, apparently ultrasonic parameters directly affect AgInS 2 Nanometer emission wavelength of the quantum dots, according to the laws of Examples 1 and 2 it can be seen, as the ultrasonic power is increased, the emission wavelength of the corresponding extension, therefore, in the actual production may be controlled to control the ultrasonic power emission wavelength QDs.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com