Sludge granulation method

A technology of sludge granulation and inoculation of sludge, applied in anaerobic digestion treatment, etc., can solve problems such as long time, easy loss of chemicals, difference in density between crystal nuclei and original sludge, etc., to strengthen cohesion and accelerate granulation speed, reducing the loss of granulation nuclei

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

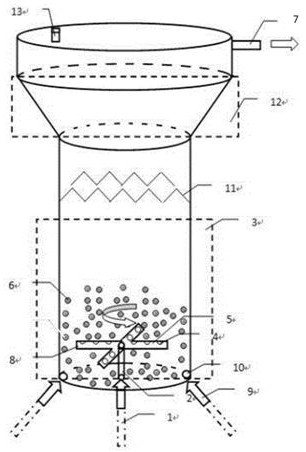

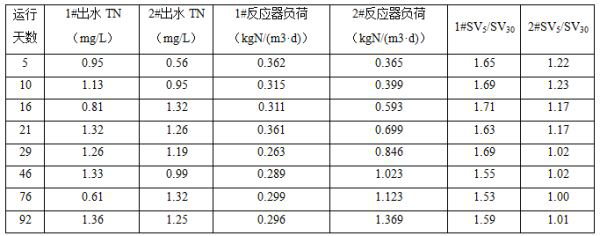

[0027] Use this reactor to cultivate denitrification granular sludge, wherein 1# is used as a control group to directly add broken granular sludge for granulation cultivation, and 2# uses the method of the present invention to pretreat the sludge, adding zero-valent iron and polyferric sulfate Increase the inoculated sludge density, the sludge concentration is 4000 mg / L, the crystal nucleus sludge concentration is 200 mg / L, the influent is municipal secondary sedimentation tank wastewater, the nitrate nitrogen content is 10-15 mg / L, and the influent COD The compound carbon source is sodium acetate and methanol, about 40-60 mg / L, the rising flow rate of 1# reactor is 3m / h, and the rising flow rate of 2# reactor is 5m / h. With the operation of the reactor, it will gradually increase to 10 m / h h. During the operation, the No. 1 reactor had the phenomenon of flocculent sludge loss and particle granulation nuclei deposition, and the operation effect of the 2# reactor was obviously b...

Embodiment 2

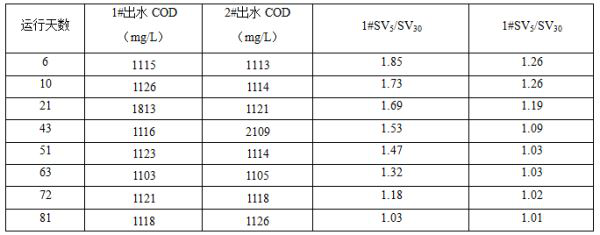

[0031] Use this reactor to cultivate anaerobic granular sludge, wherein 1# directly adds crushed granular sludge as a control group and carries out granulated cultivation, and 2# utilizes the method of the present invention to carry out pretreatment to sludge, using calcium chloride and sodium carbonate and Polyaluminum chloride increases the sludge density, the inoculated sludge concentration is 9000 mg / L, the crystal nucleus sludge concentration is 2000 mg / L, the influent is starch wastewater, and the influent COD is about 9000mg / L±1000mg / L, 1 The rising flow rate of #reactor is 3m / h, and the rising flow rate of 2# reactor is 5m / h. With the progress of granulation, the loads of both reactors are increased to 8-10 m / h. In the early stage of 1# reactor, there were sludge loss phenomenon and stratification phenomenon of crystal nuclei and inoculated sludge, and the sedimentation performance and granulation degree of 2# reactor sludge were obviously better than those of 1# reacto...

Embodiment 3

[0035]Use this reactor to cultivate denitrification granular sludge, wherein 1# is used as a control group to directly add broken granular sludge for granulation cultivation, and 2# utilizes the method of the present invention to pretreat the sludge, using calcium chloride and sodium carbonate and Polyaluminum chloride increases the sludge density, the sludge concentration is 9000 mg / L, the crystal nucleus sludge concentration is 500 mg / L, the influent is oxalic acid production wastewater, and the nitrate nitrogen content is 800-1200 mg / L. The concentration of nitrite nitrogen is 50~150mg / L, the influent COD is 800-1000 mg / L, and the carbon source is compounded with sodium acetate and methanol to make C / N=4, and the rising flow rate of 1# reactor is 3 m / h, the rising flow rate of 2# reactor is 5m / h, and gradually increases to 10m / h as the reactor runs. During the operation, a large amount of flocculent sludge was lost in the No. 1 reactor, and the rising flow rate dropped to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com