EVA treating agent and preparation method thereof

A treatment agent and cross-linking agent technology, applied in the field of EVA treatment agent and its preparation, can solve problems such as volatile, environmental pollution, health impact of operators, etc., and achieve good weather resistance, excellent permeability, and good treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The preparation method of above-mentioned EVA treatment agent, comprises the following steps:

[0028] A. Mix methylcyclohexane and cyclohexane, stir evenly, add SBS, EVA-265 and maleic anhydride to stir, start heating and fill with nitrogen to protect until the reaction is complete;

[0029] B. After complete dissolution, when the internal temperature reaches 80°C, add hydroxyethyl methacrylate and methyl methacrylate to mix, and stir evenly;

[0030] C. When the internal temperature reaches 80°C-85°C, add dibenzoyl peroxide and dimethyl carbonate to ethyl acetate and stir to dissolve, add to the mixture obtained in step B, and add a crosslinking agent, stir and mix evenly and then keep the temperature Start the reaction at 85°C-90°C for 4 hours, then cool down to terminate the reaction;

[0031] D. When the internal temperature drops below 50°C, add anti-aging agent and stir to mix;

[0032] E. Add chlorinated polyethylene, chlorinated rubber, and dibutyl hydroxytol...

Embodiment 1-3 and comparative example 1-5

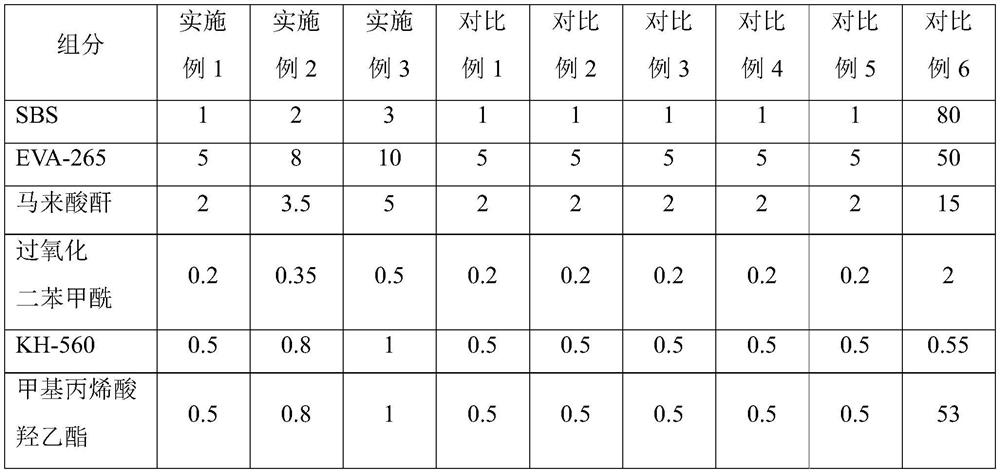

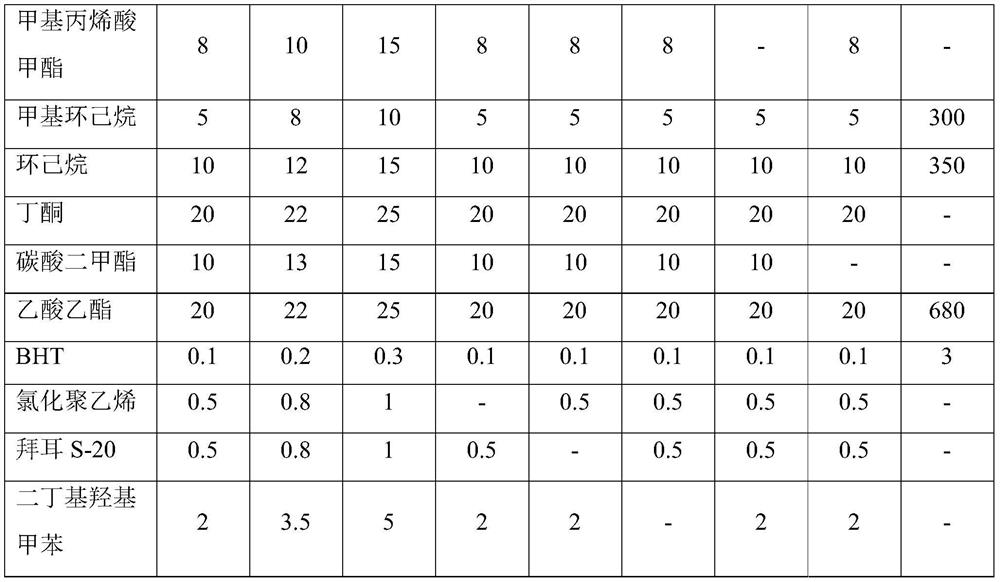

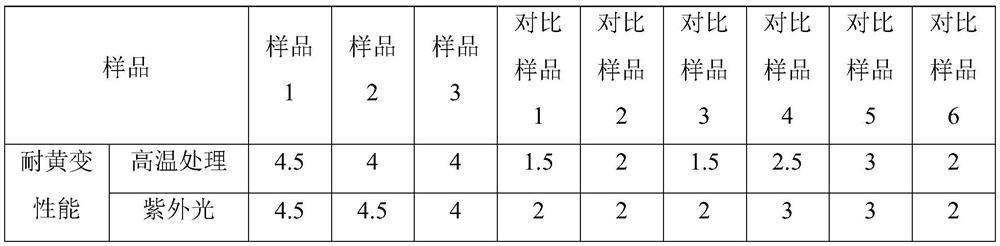

[0035] Examples 1-3 and Comparative Examples 1-5 were prepared according to the components in parts by mass shown in Table 1 below.

[0036] Table 1 embodiment 1-3 and comparative example 1-5 group distribution ratio

[0037]

[0038]

Embodiment 1

[0040] An EVA treatment agent is prepared according to the following preparation method, and the following parts are parts by mass:

[0041] A. Mix 5 parts of methylcyclohexane and 10 parts of cyclohexane, stir evenly, add 1 part of SBS, 5 parts of EVA-265 and 2 parts of maleic anhydride, stir, start heating and fill with nitrogen to protect until the reaction is complete;

[0042] B. After complete dissolution, when the internal temperature reaches 80°C, add 0.5 parts of hydroxyethyl methacrylate and 8 parts of methyl methacrylate to mix, and stir evenly;

[0043] C. When the internal temperature reaches 80°C-85°C, add 0.2 parts of dibenzoyl peroxide and 10 parts of dimethyl carbonate to 20 parts of ethyl acetate and stir to dissolve, add to the mixture obtained in step B, and add 0.5 parts of KH -560, Stir and mix evenly, then start the reaction at a constant temperature of 85°C-90°C for 4 hours, then cool down to terminate the reaction;

[0044] D. Add 0.1 parts of BHT whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com