Carbon black master batch for polycarbonate engineering plastic and preparation method of carbon black master batch

A technology of polycarbonate and engineering plastics, applied in the field of carbon black masterbatch of polycarbonate engineering plastics and its preparation, can solve the problem of poor flow characteristics, wear resistance, oil resistance and low temperature impact resistance, injection molding Trouble and other problems, to achieve the effect of reducing melt viscosity, weakening the agglomeration effect, and improving processing fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

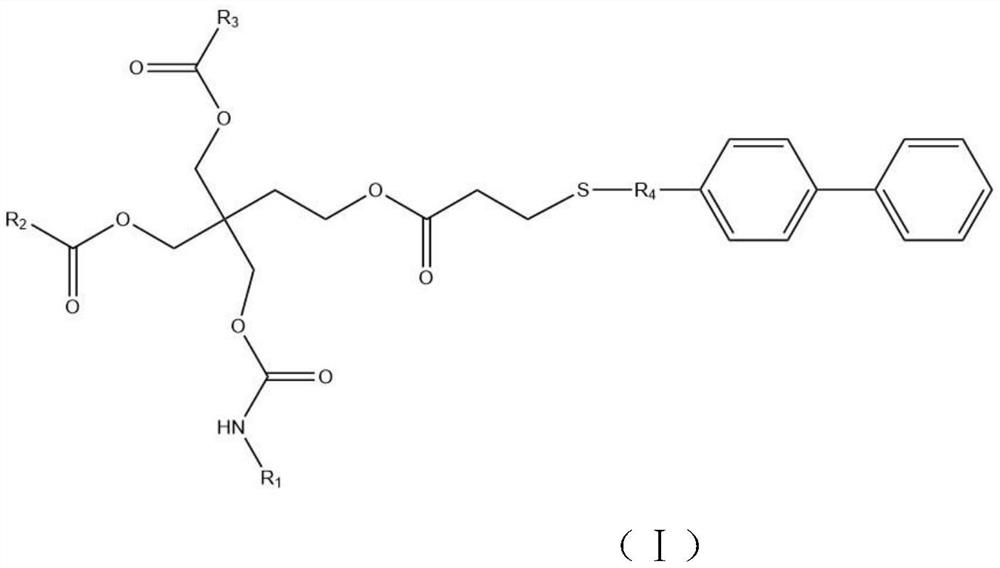

[0041] A kind of preparation method of dispersant that present embodiment relates to comprises the steps:

[0042] (1) In a reaction kettle equipped with a water separator and a thermometer, feed nitrogen gas, add pentaerythritol, mercaptopropionic acid, methanesulfonic acid, and cyclohexane, start stirring, and heat to 100°C to reflux and separate water to reach the theoretical water output Stop the reaction afterward, remove hexanaphthene, and wash and filter with water, obtain the first intermediate after removing water;

[0043] (2) After vacuumizing PTMG1000 (polytetrahydrofuran) and BDO (1,4-butanediol) at 110°C to remove water, add dibutyltin dilaurate and MDI (diphenylmethane-4,4'- diisocyanate), heated up to 100°C, and reacted for 3 hours to obtain an NCO-terminated thermoplastic polyurethane with an R value of 1.1; then add the first intermediate to continue the reaction for 2 hours to obtain the second intermediate;

[0044] (3) Dissolve the second intermediate, ph...

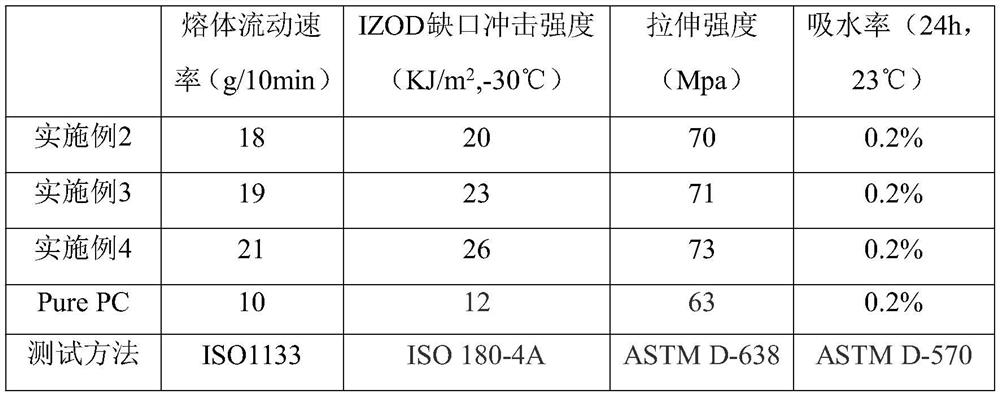

Embodiment 2

[0048] A kind of preparation method for the carbon black masterbatch of polycarbonate engineering plastics that the present embodiment relates to comprises the steps:

[0049] S1. Add 35 parts of carbon black and 10 parts of dispersant (A1) into N-methylpyrrolidone, perform ultrasonic dispersion and mixing, and dry after mixing evenly;

[0050] S2. Dry the polycarbonate (melt flow rate is 10g / 10min) at 150°C until the humidity is less than 0.02%;

[0051] S3. Mix the mixture obtained in step S1 with 55 parts of dried polycarbonate carrier resin, 0.01 part of PPA2511 and 1 part of N, N'-bis-(3-(3,5-di-tert-butyl-4-hydroxyl Phenyl) propionyl) hexamethylenediamine is dropped into speed and mixes for 900r / min high-speed mixer;

[0052] S4. The pre-mixture obtained in step S2 is melted and pressed into tablets, and then extruded through high-speed banburying and water-cooled pelletizing to obtain carbon black masterbatches for polycarbonate engineering plastics.

Embodiment 3

[0054] A kind of carbon black masterbatch preparation method for polycarbonate engineering plastics that the present embodiment relates to comprises the following steps:

[0055] S1. Add 45 parts of carbon black and 10 parts of dispersant to N-methylpyrrolidone, perform ultrasonic dispersion and mixing, and dry after mixing evenly;

[0056] S2. Dry the polycarbonate (melt flow rate is 10g / 10min) at 150°C until the humidity is less than 0.02%;

[0057] S3. put the mixture obtained in step S1 and 45 parts of dried polycarbonate carrier resin, 0.05 part of PPA3511 and 1 part of 2.4-dimethyl-6-styrene phenol into a high-speed mixer with a speed of 900r / min mix;

[0058] S4. The pre-mixture obtained in step S2 is melted and pressed into tablets, and then extruded through high-speed banburying and water-cooled pelletizing to obtain carbon black masterbatches for polycarbonate engineering plastics.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com