Transition metal compound hydrogen evolution film and radio frequency backwash modification preparation method

A technology of transition metals and compounds, applied in the field of electrocatalytic hydrogen evolution, to achieve the effect of improving catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] like figure 1 As shown, a transition metal compound hydrogen evolution thin film includes a base layer and a hydrogen evolution catalytic layer, the hydrogen evolution catalytic layer is arranged on the surface of the base layer, and the hydrogen evolution catalytic layer is a transition metal sulfur compound, a transition metal selenium compound and one of the transition metal tellurium compounds.

[0035] In this embodiment, the hydrogen evolution catalytic layer is MoS 2 、WS 2 、MoSe 2 、WSe 2 、MoTe 2 and WTe 2 A film made of one of the materials.

[0036] In this embodiment, the base layer is made of metal or ceramics;

[0037] When the base layer is metal, the metal is V, Nb, Ta, Mo, Ni, Ti, Pd, Pt, porous stainless steel, V / Ni alloy, V / Cr alloy, V / Cu alloy, V / Fe alloy, V / Al alloy, V / Co alloy, V / Mo alloy, V / W alloy, V / Ti / Ni alloy, V / Fe / Al alloy, V / Mo / W alloy, Nb / Ti / Ni alloy, Nb / Ti / One of Co alloy and Nb / Mo / W alloy;

[0038] When the base layer is ceramic,...

Embodiment 2

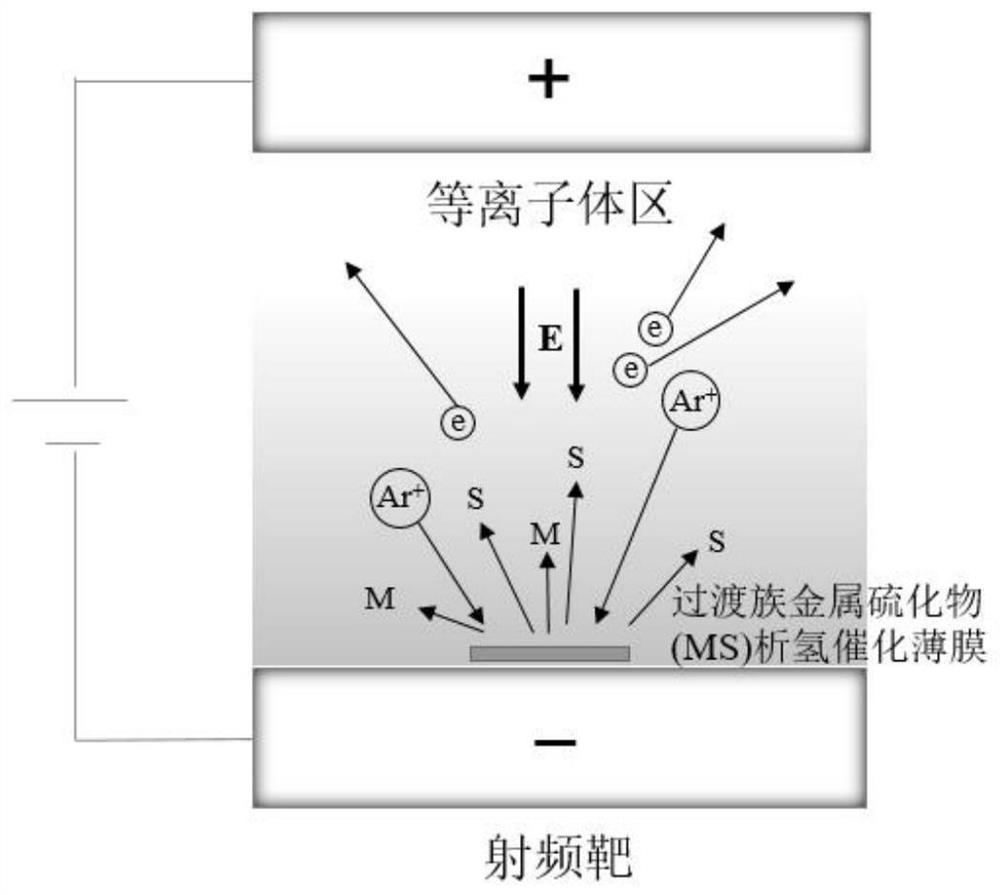

[0040] A method for preparing a transition group metal compound hydrogen evolution thin film by radio frequency backsputtering modification, characterized in that, according to the following steps:

[0041] Step 1: pretreating the base layer 1;

[0042] Step 2: cleaning the surface of the base layer 1 with an ion beam;

[0043] Step 3: using one of chemical vapor deposition, hydrothermal synthesis, magnetron sputtering, ion beam sputtering, electron beam evaporation, pulse deposition, molecular beam epitaxy and atomic layer deposition to form a hydrogen evolution catalytic layer 2 on the surface of the base layer 1 ;

[0044] Step 4: irradiating and etching the surface of the hydrogen evolution catalytic layer 2 by means of radio frequency backsputtering.

[0045] In this embodiment, in step 1, the base layer is ultrasonically cleaned for 5-15 minutes with acetone and absolute ethanol in sequence, repeated 2-3 times, and then rinsed with deionized water for 1-2 minutes, and th...

Embodiment 3

[0052] Referring to the preparation method of radio frequency backsputtering modification in Example 2, the sputtering power in Step 4 is 100V, the irradiation time is 2min, and the other steps and parameters are the same as in Example 2.

[0053] The obtained SEM image is as Figure 4 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com