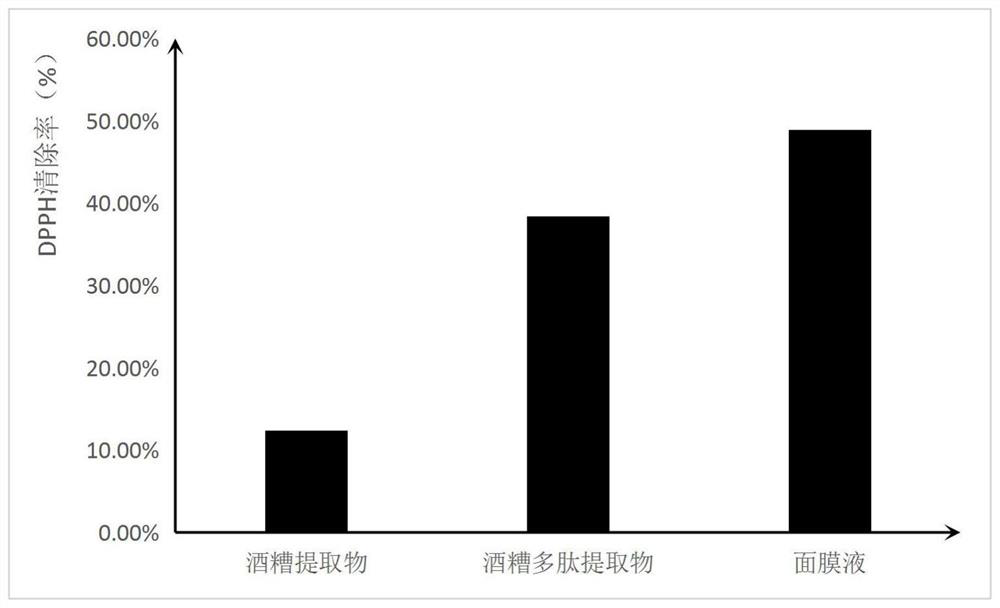

Rice vinasse polypeptide mask as well as preparation method and application thereof

A technology of rice distiller's grains and peptide mask, which is applied in the preparation of alcoholic beverages, pharmaceutical formulas, and cosmetic preparations, etc. It can solve the problems of difficult preservation, environmental pollution, and low efficiency of comprehensive utilization of distiller's grains, and achieve resource saving and simple and easy process The effect of the operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

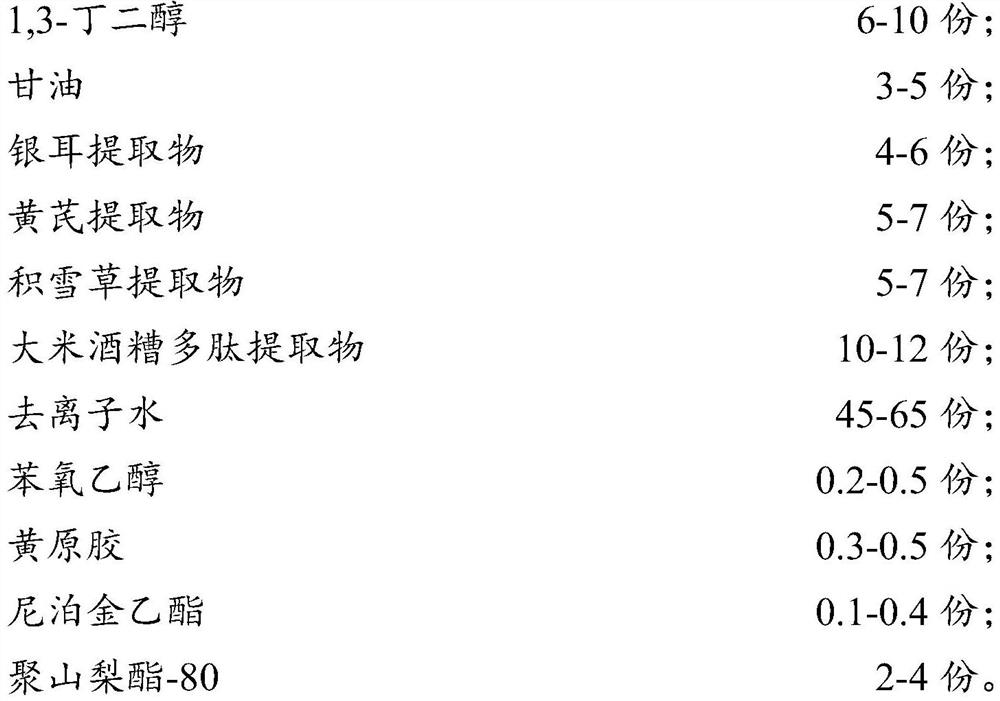

Embodiment 1

[0082] A rice distiller's grains polypeptide mask, comprising the following raw materials: 1,3-butanediol 8g, glycerin 4g, white fungus extract 5g, astragalus extract 6g, centella asiatica extract 6g, rice distiller's grains polypeptide extract 11g, phenoxyethanol 0.3g, xanthan gum 0.4g, ethylparaben 0.2g, polysorbate-803g, deionized water 50g.

[0083] In order to further optimize the above-mentioned technical scheme, the preparation of rice distiller's grains extract specifically includes:

[0084] (11) Rice distiller's grains are dried under reduced pressure, pulverized and sieved to obtain distiller's grains powder;

[0085] Among them, the decompression drying temperature is 40°C, the pressure is 0.04MPa, dried for 3 hours, and sieved through a 60-mesh sieve;

[0086] (12) dissolving distiller's grains powder in deionized water, and adding alkaline protease for enzymolysis to obtain a hydrolyzate;

[0087] Among them, the mass ratio of distiller's grain powder to deioni...

Embodiment 2

[0123] A rice distiller's grains polypeptide mask, comprising the following raw materials: 1,3-butanediol 6g, glycerin 3g, white fungus extract 4g, astragalus extract 5g, centella asiatica extract 5g, rice distiller's grains polypeptide extract 10g, phenoxyethanol 0.2g, xanthan gum 0.5g, ethylparaben 0.1g, polysorbate-802g, deionized water 65g.

[0124] In order to further optimize the above-mentioned technical scheme, the preparation of rice distiller's grains extract specifically includes:

[0125] (11) Rice distiller's grains are dried under reduced pressure, pulverized and sieved to obtain distiller's grains powder;

[0126] Among them, the decompression drying temperature is 50°C, the pressure is 0.05MPa, dried for 3.5h, and sieved through a 60-mesh sieve;

[0127] (12) dissolving distiller's grains powder in deionized water, and adding alkaline protease for enzymolysis to obtain a hydrolyzate;

[0128] Among them, the mass ratio of distiller's grain powder to deionized...

Embodiment 3

[0165] A rice distiller's grains polypeptide mask, comprising the following raw materials: 1,3-butanediol 10g, glycerin 5g, white fungus extract 6g, astragalus extract 7g, centella asiatica extract 7g, rice distiller's grains polypeptide extract 12g, phenoxyethanol 0.5g, xanthan gum 0.3g, ethylparaben 0.4g, polysorbate-804g, deionized water 45g.

[0166] In order to further optimize the above-mentioned technical scheme, the preparation of rice distiller's grains extract specifically includes:

[0167] (11) Rice distiller's grains are dried under reduced pressure, pulverized and sieved to obtain distiller's grains powder;

[0168] Among them, the decompression drying temperature is 60°C, the pressure is 0.06MPa, the drying time is 4h, and sieved through a 60-mesh sieve;

[0169] (12) dissolving distiller's grains powder in deionized water, and adding alkaline protease for enzymolysis to obtain a hydrolyzate;

[0170] Among them, the mass ratio of distiller's grain powder to d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com