Chromium-based MOF adsorbent for H2S gas removal and preparation method of chromium-based MOF adsorbent

An adsorbent and gas technology, applied in the field of chromium-based MOF adsorbent and its preparation, can solve problems such as discount of adsorption efficiency, and achieve the effects of improved adsorption capacity, low device requirements and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] This embodiment provides a kind of preparation method of chromium-based MOF adsorbent, comprising the following steps:

[0027] a) Add Cr(NO 3 ) 3 9H 2 O (2 g, 0.005 mmol) and 2-aminophthalic acid (0.9 g, 0.005 mmol) were sonicated for 10 min so that the solution was well mixed.

[0028] b) The solution was transferred to a Teflon-lined autoclave and heated to 200°C for 24h.

[0029] c) After heating, the solution was naturally cooled to room temperature, and a light green solid was obtained by suction filtration.

[0030] d) Put the solid into 300mL N,N-dimethylformamide (DMF), heat to 100°C, stir for 24h, and remove the residual reactants.

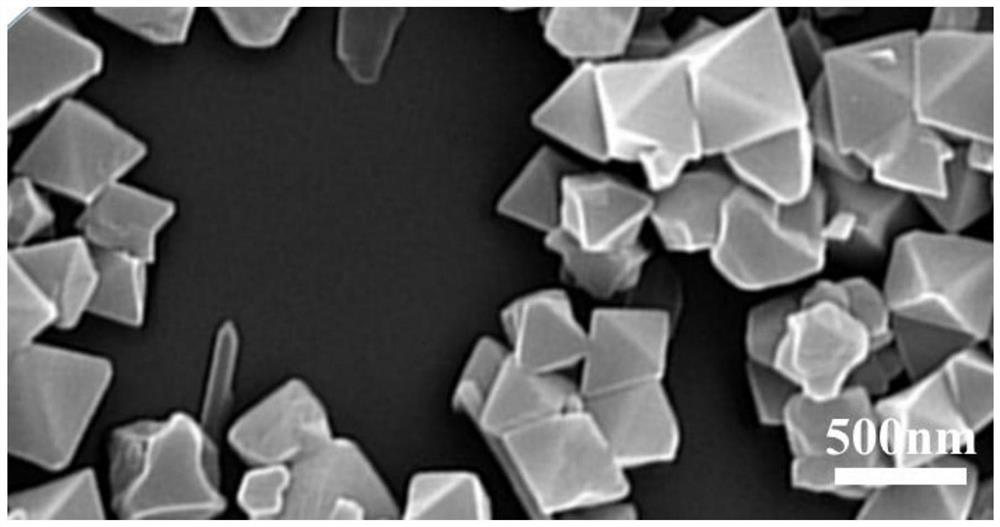

[0031] e) Then put the above suspension into 400mL ethanol and stir at room temperature for 18h to remove the DMF in the pores. The final green product was vacuum filtered and dried at 200°C for 12 hours to obtain a chromium-based MOF adsorbent named MIL-101, whose structure and morphology are as follows: figure 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com