Method and device for recycling tetramethylammonium hydroxide in developing waste liquid

A technology of tetramethylammonium hydroxide and tetramethylammonium salt, applied in chemical instruments and methods, purification/separation of amino compounds, organic chemistry, etc., can solve the problem of increasing electricity and steam energy consumption costs, difficult treatment, and recovery rate No high-level problems, easy to promote and use, energy saving and environmental protection in the process, continuous production effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

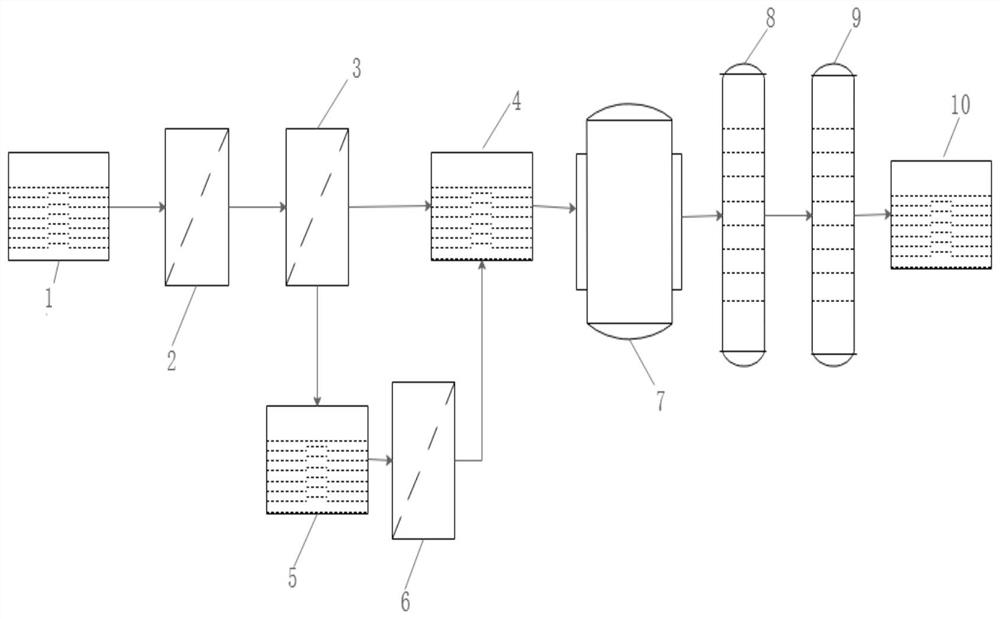

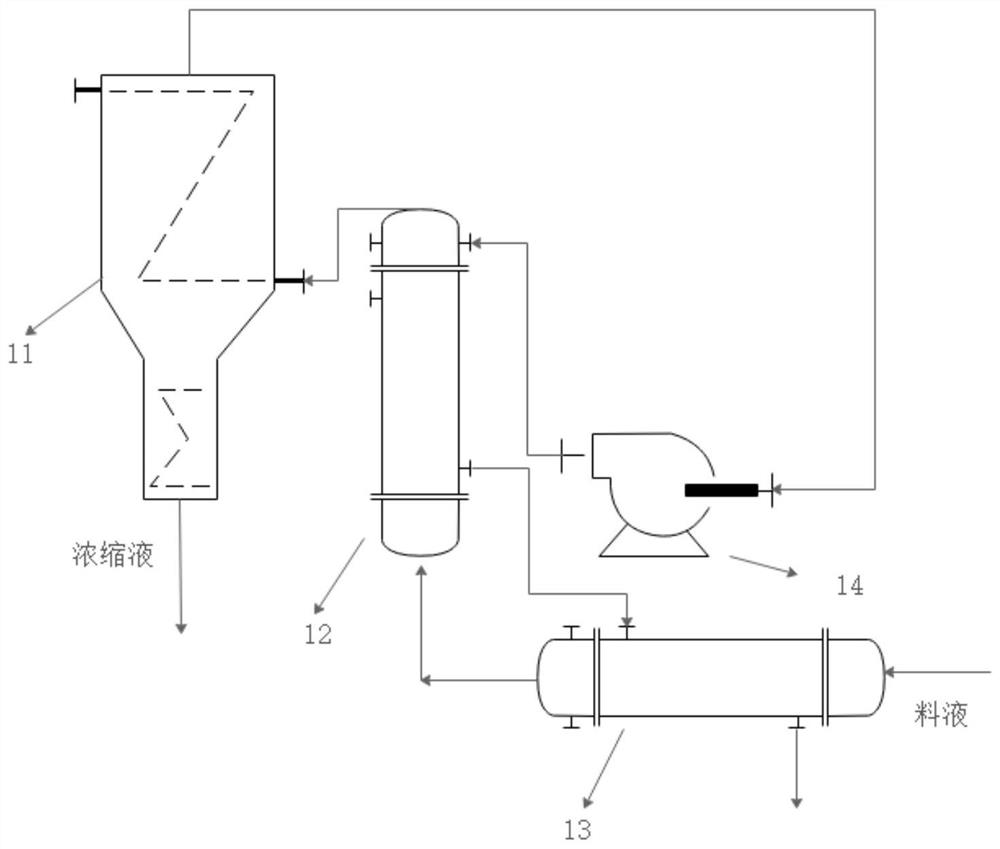

Method used

Image

Examples

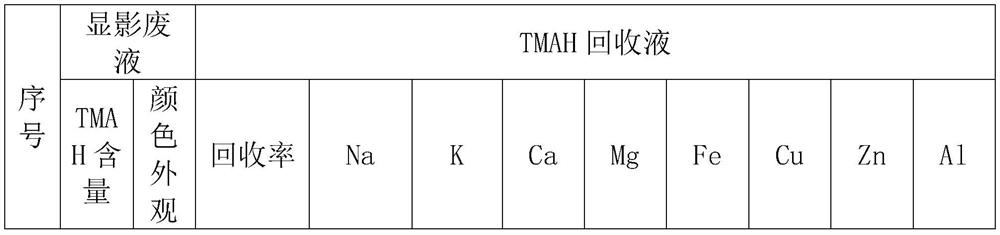

Embodiment 1

[0034] Take 6L of developing waste liquid, in which the TMAH content is 0.762%, and the color appearance is dark brown. Both adjustment tanks are adjusted to pH 5 with hydrochloric acid. Both the first and second filter devices use 10 μm filter elements, and the cation exchange resin column uses macropores. Type strong acid resin and chelating resin mixed resin, anion exchange resin column selection of hydroxide type anion exchange resin column, the resulting final TMAH solution recovery and metal ion indicators are as follows.

Embodiment 2

[0036] Take 6L of developing waste liquid, in which the TMAH content is 0.593%, and the color appearance is dark brown. Both adjustment tanks are adjusted to pH 3 with sulfuric acid. Type weakly basic resin, macroporous strong acid resin and three mixed resins of chelating resin, anion exchange resin column selection of hydroxide type anion exchange resin column, the resulting final TMAH solution recovery and metal ion indicators are as follows.

[0037]

[0038]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com