Power grid construction waste slurry or slag integrated treatment and filler utilization method

A waste mud and power grid technology, applied in sludge treatment, chemical instruments and methods, fixed/solidified sludge treatment, etc., can solve problems such as inability to directly utilize resources, decrease in curing efficiency of chemical solidification, and environmental problems, and achieve Suitable for large-scale promotion and application, fast and efficient curing treatment, and the effect of avoiding waste of land resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

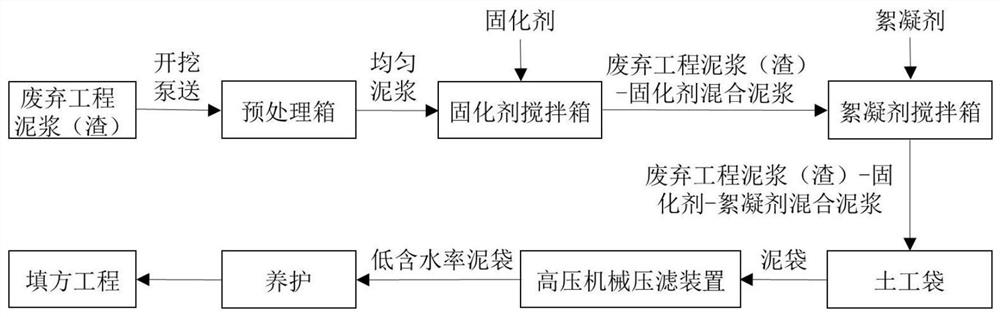

[0039] A method for integrated treatment of power grid construction waste mud or slag and utilization of fillers, such as figure 1As shown, the following steps are followed: pump the waste engineering mud (slag) mined on site to the mud pretreatment tank, and stir the waste engineering mud (slag) evenly at a rate of 60r / min to 120r / min. Pump the uniformly stirred mud into the curing agent mixing box through the pumping device, and add cement (the amount is 10% to 15% of the dry mud mass) through the curing agent delivery box at a rate of 90r / min to 150r / min Stir at a rapid rate for 10 min. Pump the waste engineering mud (slag)-curing agent mixed mud into the flocculant mixing box, and add the AN926SHUC anionic polyacrylamide flocculant solution (flocculant solid The particle dosage is 0.1%-0.2% of the dry mud mass), and the mixed mud is mixed with the flocculant evenly and flocculation deposition reaction occurs at a slow speed of 60r / min-90r / min for 10min. Then, the uniform...

Embodiment 2

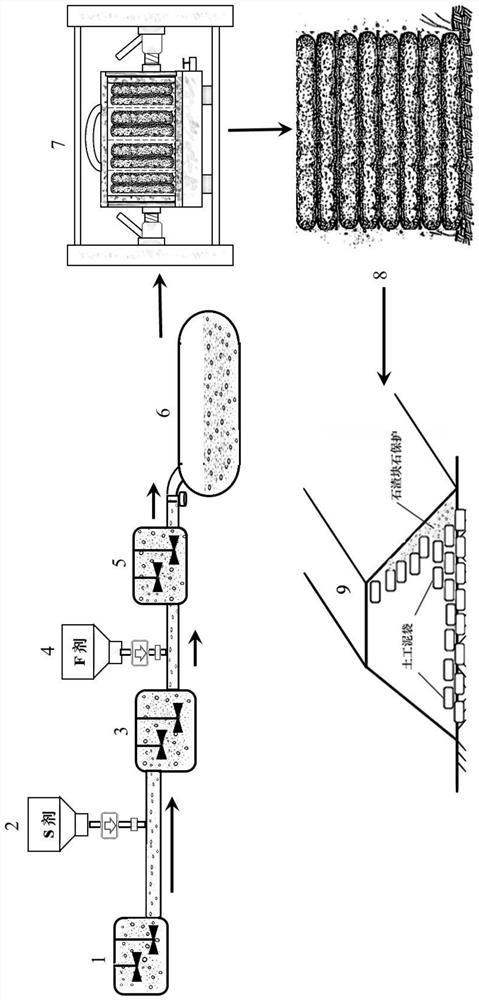

[0041] Such as figure 2 As shown, a "flocculation conditioning-solidification-mechanical filter dehydration-geotechnical mud bagging" integrated device used in the integrated treatment of waste mud or slag in power grid construction and filler utilization method, including: pretreatment box 1, curing agent Delivery box 2, curing agent mixing box 3, flocculant delivery box 4, flocculant mixing box 5, geotechnical bag 6, high pressure mechanical filter device 7, low moisture content mud bag 8, low moisture content mud bag 8 final application For filling works9.

[0042] The wide-graded waste engineering mud (slag) after mining is pumped into the pretreatment tank 1, and the waste engineering mud (slag) is stirred evenly at a rate of 60r / min-120r / min. The uniformly stirred mud is pumped into the curing agent mixing tank 3 by the pumping device of the pretreatment tank 1, and cement is added through the curing agent delivery tank 2 (the amount is 10% to 15% of the dry mud qualit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com