Vinyl functionalized phosphine ligand synthesis method, phosphine ligand and application

A vinyl functional, phosphine ligand technology, which is applied in the preparation of carbon-based compounds, chemical instruments and methods, carbon monoxide reaction preparation, etc., can solve the problem of unsatisfactory activity and stability of immobilized catalysts, low P ligand concentration, and catalyst issues such as decreased selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

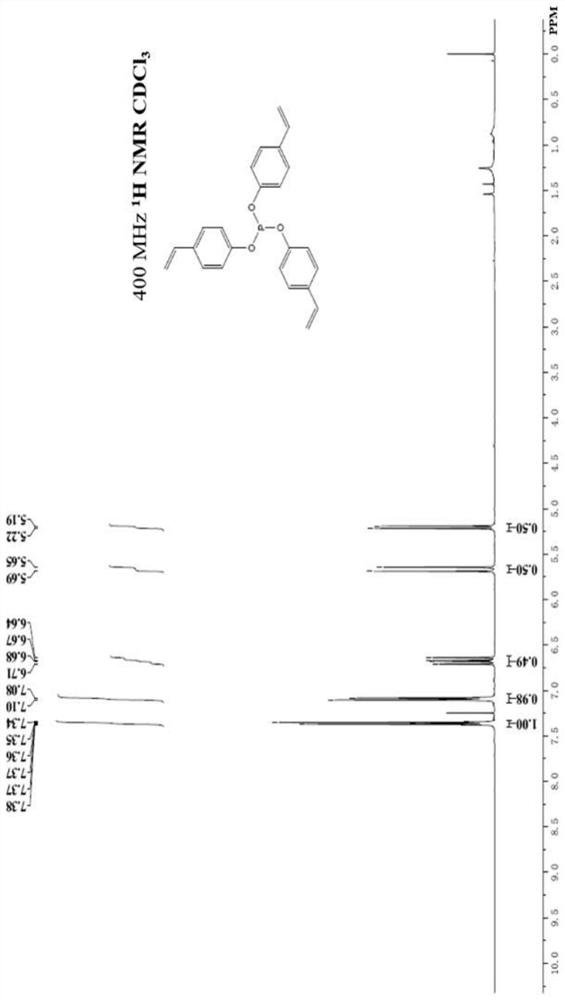

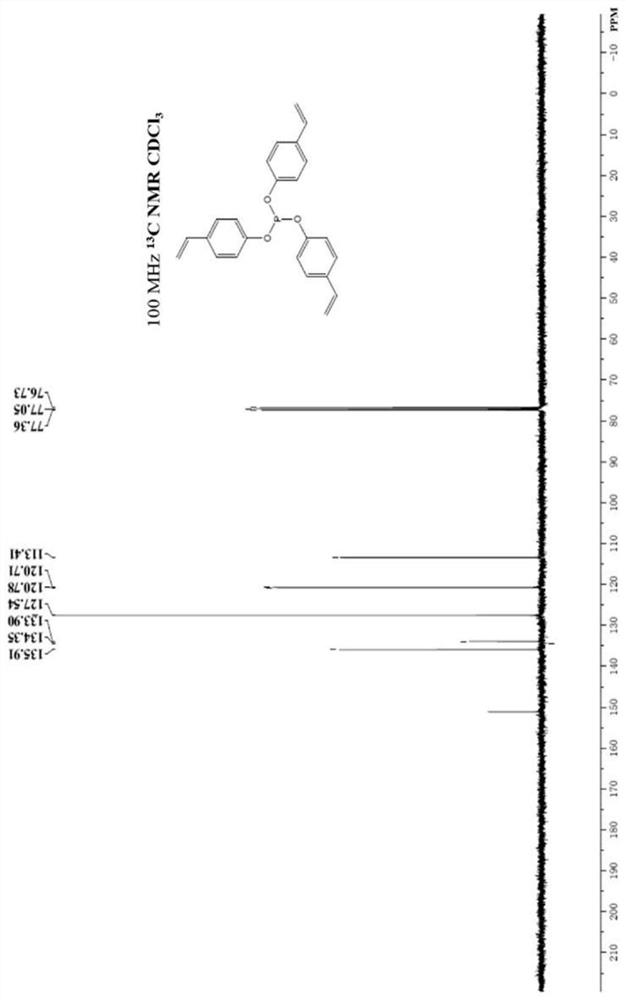

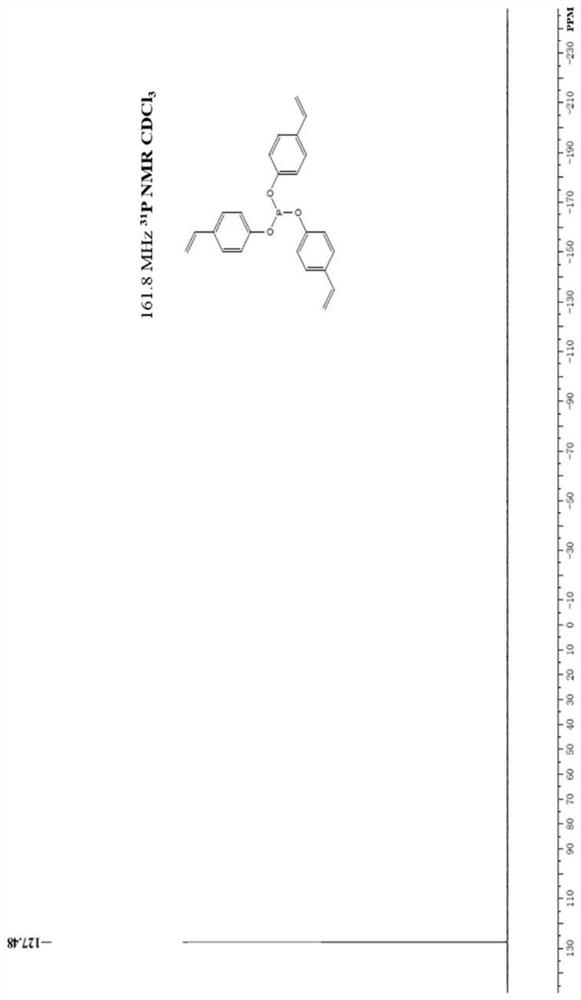

Image

Examples

Embodiment 1

[0026] Under the protection of 298K inert gas, 180kg of p-hydroxystyrene (1.5kmol), 182kg of pyridine and 3.6kg of bisphenol A (polymerization inhibitor) were dissolved in 900L of toluene, stirred for 1 hour and poured into the upper tank of the enamel reactor (material storage tank) , located on the upper part of one side of the reactor), add 70kg phosphorus trichloride and 70L toluene to the enamel reactor, adjust the temperature of the reactor to T1 degrees Celsius, and drop the mixed solution of the head tank into the reactor at T1°C, drop After the addition was complete, the reaction was continued for 1 hour.

[0027] Under the protection of 298K inert gas, the pH of the reaction solution was adjusted to 6 with 2% (mass concentration) hydrochloric acid solution, and the reaction was fully annihilated after stirring for 1 hour. After standing for 2 hours, the mixed solution was divided into two layers, and the upper oil layer was taken out. Filter through 10cm thick silica...

Embodiment 2

[0032] Under the protection of 298K inert gas, 180kg of m-hydroxystyrene (1.5kmol), 182kg of pyridine and 3.6kg of bisphenol A (polymerization inhibitor) were dissolved in 900L of toluene (reaction solvent). Add 70kg of phosphorus trichloride and 70L of toluene (reaction solvent) into the enamel reaction kettle, adjust the temperature of the reaction kettle to T1 degrees Celsius, drop the mixed solution of the high level tank into the reaction kettle at T1℃, and continue the reaction after the addition is completed 1 Hour.

[0033] Under the protection of 298K inert gas, the pH of the reaction solution was adjusted to 6 with 2% (mass concentration) hydrochloric acid solution, and the reaction was fully annihilated after stirring for 1 hour. After standing for 2 hours, the mixed solution was divided into two layers, and the upper oil layer was taken out. Filter through diatomaceous earth with a thickness of 10cm, and distill off the solvent at 100°C to obtain a light yellow oil...

Embodiment 3

[0037] Under the protection of 298K inert gas, 180kg of o-hydroxystyrene (1.5kmol), 182kg of pyridine and 3.6kg of bisphenol A were dissolved in 900L of toluene. Phosphorus and 70L toluene, adjust the temperature of the reactor to T1°C, add the mixed solution of the high level tank to the reactor at T1°C, and continue to react for 1 hour after the dropwise addition is completed.

[0038] Under the protection of 298K inert gas, adjust the pH of the reaction solution to 6 with (mass concentration) 2% hydrochloric acid solution, stir for 1 hour to fully annihilate the reaction, and after standing for 2 hours, the mixed solution is divided into two layers, the upper oil layer is taken out, and the oil layer is passed through Filter through 10cm thick diatomaceous earth, distill off the solvent at 100°C to obtain a light yellow oily liquid, add 80kg of ethanol to heat the mixed solvent to 100°C to fully dissolve, then cool down to 5°C to recrystallize and dry to obtain vinyl Functi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com