Porous aromatic framework epaf-2 material and cl-20@epaf-2 composite energetic material and preparation method

An EPAF-2, porous aromatic skeleton technology, applied in nitroalkane compositions, explosives, etc., can solve the problems that limit the practical application of porous material-based energetic materials, the structural design is not strong, and the skeleton does not contain energy, etc. Achieve the effect of meeting the requirements of industrial production, high energy density and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

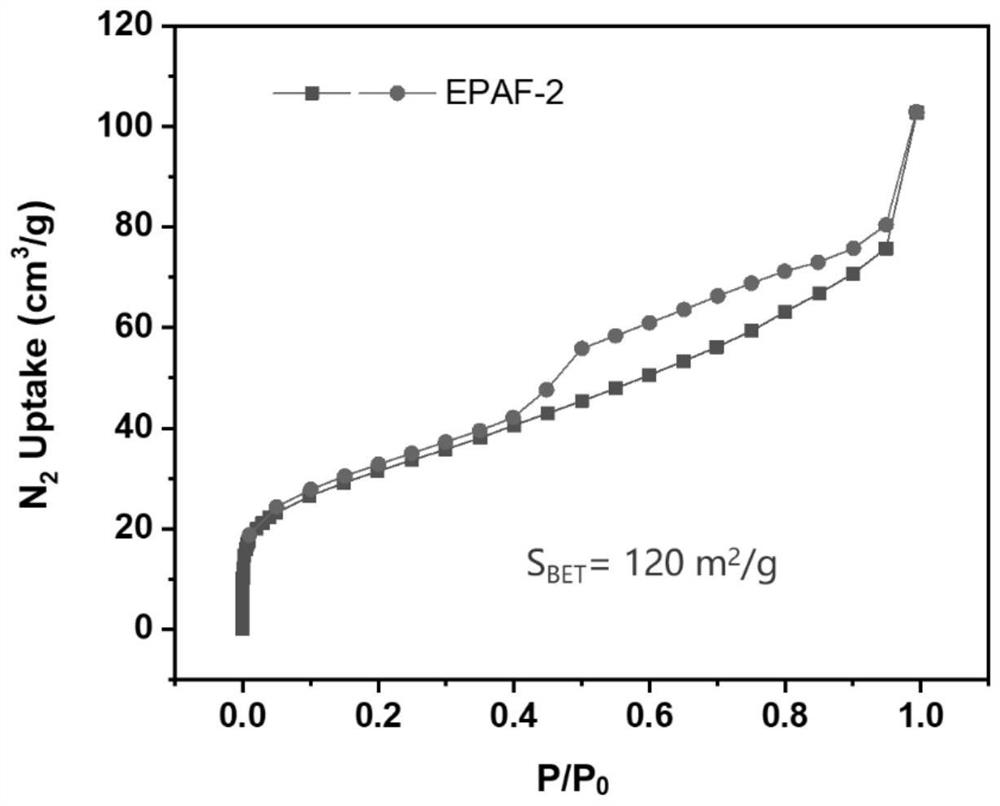

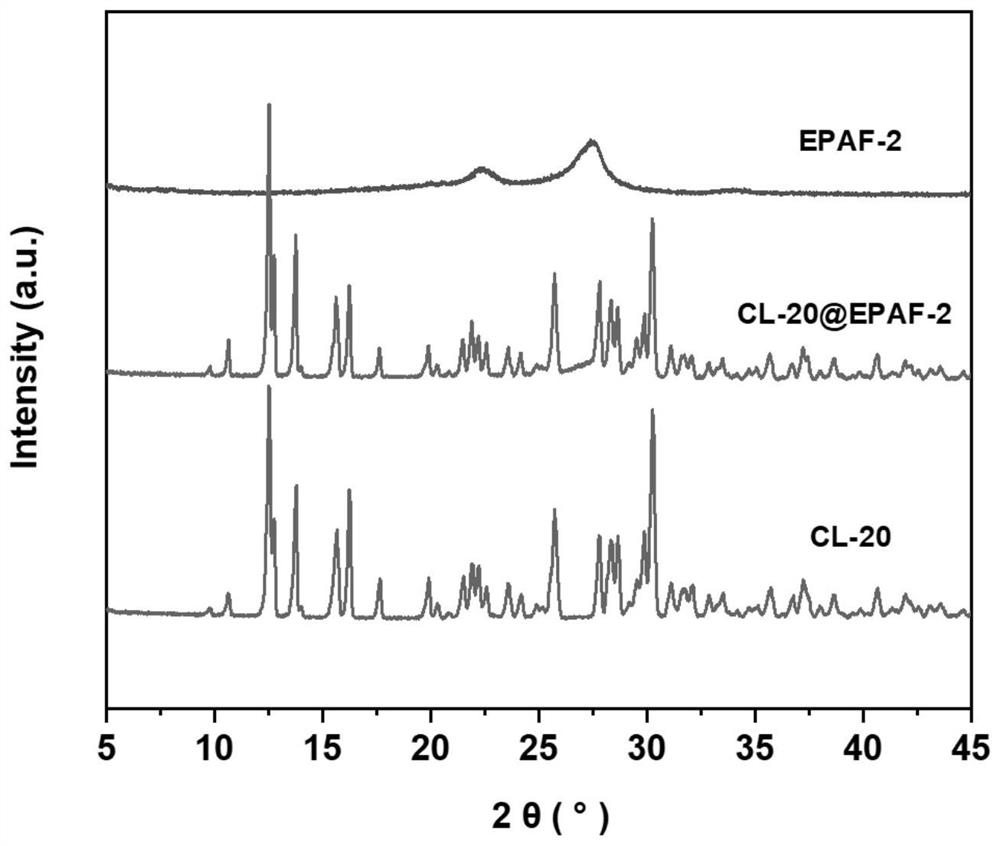

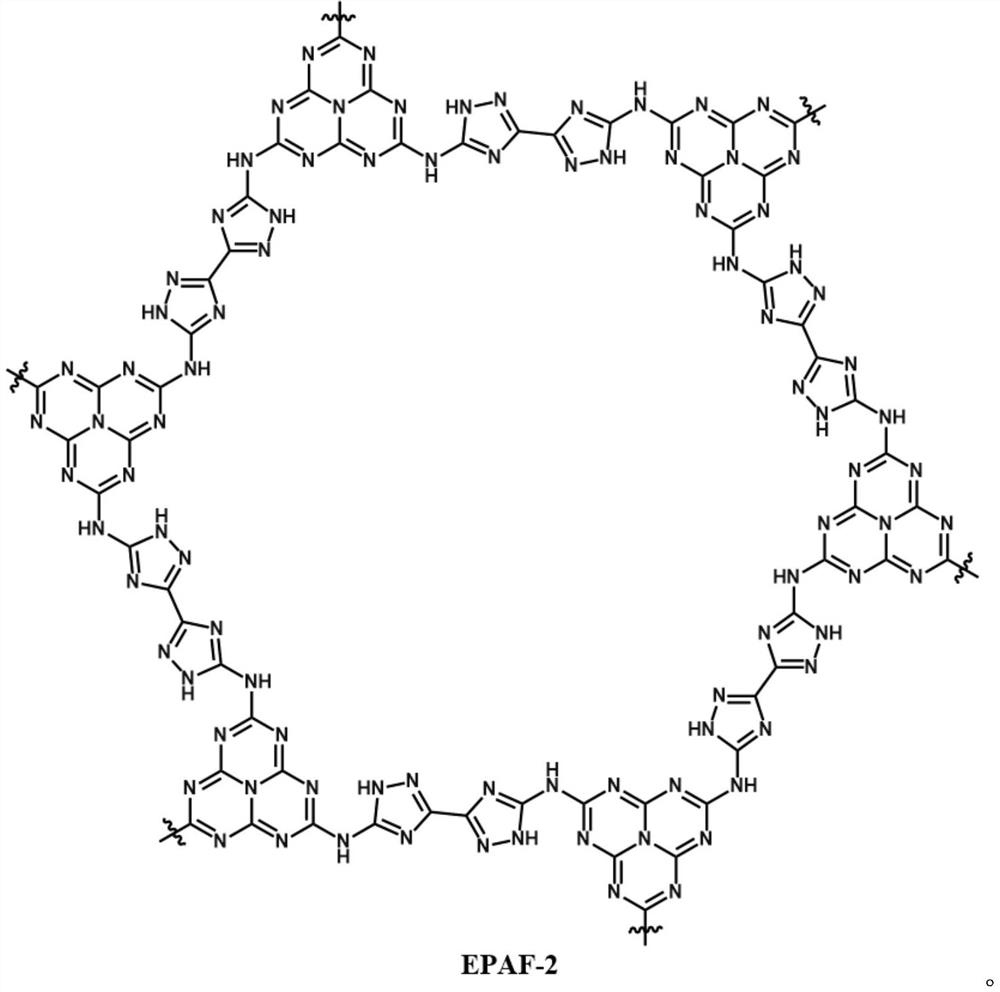

[0024] The present invention uses energetic monomer cyanuric acid chloride and 5,5'-diamino-3,3'-bi-1,2,4-triazole (DABT) as raw materials to polymerize g-C 3 N 4 The synthetic route and structural diagram of the energetic porous aromatic framework EPAF-2 material:

[0025]

[0026] Weigh 138.5mg of cyanowhite uric acid chloride (0.5mmol) and 124.5mg of DABT (0.75mmol) into a 10mL pyrex glass tube, add 2mL of mesitylene and 0.3mL of N,N diisopropylethylamine (DIPEA) , sonicate the mixed solution for 5 min. The freezing and pumping operation was carried out under the protection of nitrogen and liquid nitrogen, and three cycles of freezing-vacuumizing-thawing were performed, and then the tube was sealed under a butane / oxygen flame under vacuum conditions. When the glass tube containing the mixed solution rose to room temperature, it was placed in an oven at 180° C. for 3 days to react. The glass tube was removed from the oven to cool to room temperature, and the product wa...

Embodiment 2

[0033]Weigh 138.5mg cyanowhite uric acid chloride (0.5mmol) and 124.5mg DABT (0.75mmol) in a 10mL pyrex glass tube, add 2mL o-dichlorobenzene and 0.3mL N,N diisopropylethylamine (DIPEA ), the mixed solution was ultrasonicated for 5 min. The freezing and pumping operation was carried out under the protection of nitrogen and liquid nitrogen, and three cycles of freezing-vacuumizing-thawing were performed, and then the tube was sealed under a butane / oxygen flame under vacuum conditions. When the glass tube containing the mixed solution rose to room temperature, it was placed in an oven at 180° C. for 3 days to react. The glass tube was removed from the oven to cool to room temperature, and the product was filtered. Then wash with ethanol, boiling water, and ethanol respectively, and dry in vacuum at 80° C. overnight to obtain the porous aromatic skeleton EPAF-2 material. Weigh 600mg of CL-20 into a glass bottle, add 5mL of acetone and 5mL of n-hexane mixed solvent to fully diss...

Embodiment 3

[0035] Weigh 1.39g cyanowhite uric acid chloride (5mmol) and 1.25g DABT (7.5mmol) in a 100mL two-necked bottle, add 20mL mesitylene and 3mL N,N diisopropylethylamine (DIPEA), and ultrasonicate the mixed solution a period of time. Under the protection of nitrogen, the reaction was stirred in an oil bath at 180°C for 3 days, and the product was filtered. Wash with ethanol and boiling water respectively, and dry under vacuum at 80°C overnight to obtain the porous aromatic framework EPAF-2 material. Weigh 600mg of CL-20 into a glass bottle, add 5mL of acetone and 5mL of n-hexane mixed solvent to fully dissolve it, and then add 200mg of EPAF-2 material. Put the glass bottle in an oil bath at 50°C, and keep stirring with the open door open (stirring rate is 200r / min) until a dry solid powder is obtained, and the CL-20@EPAF-2 composite with 75wt% CL-20 doping amount can be obtained Energetic materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com