Texturing additive suitable for monocrystalline silicon wafer and application

A monocrystalline silicon wafer and additive technology, applied in the direction of single crystal growth, single crystal growth, sustainable manufacturing/processing, etc., can solve the problems of increased production cost, complicated process flow, increased chemical alkali consumption, etc., and achieve reduction Consumption, simplification of process flow, and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

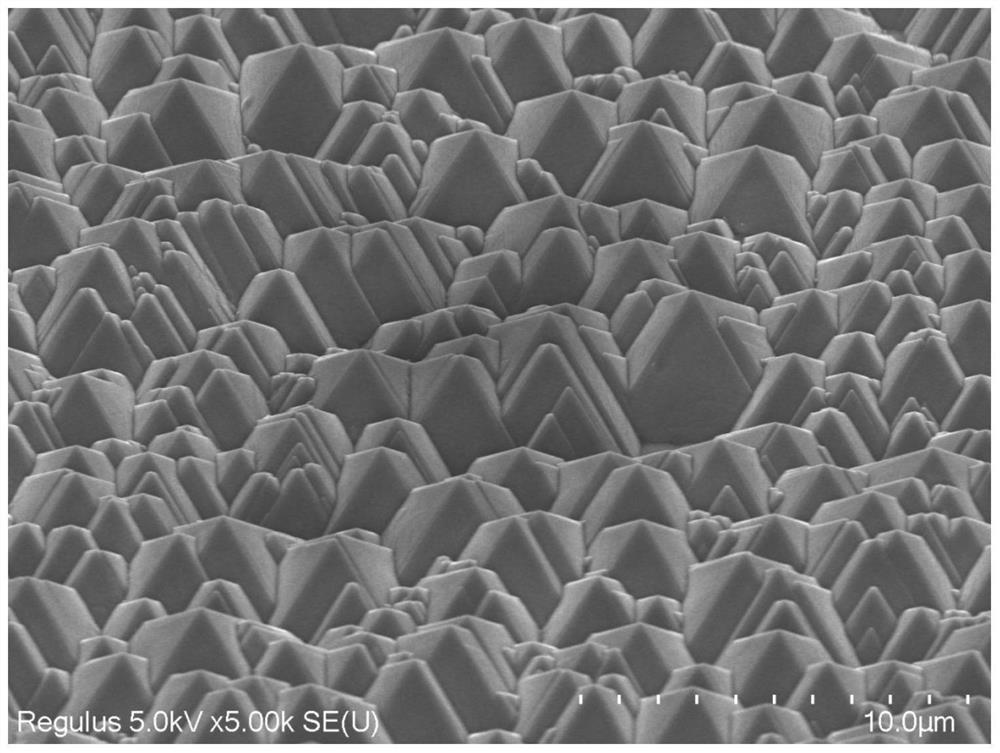

Image

Examples

Embodiment 1

[0031] The texturing method of monocrystalline silicon chip of the present invention, concrete steps comprise:

[0032] (1) Preparation of velvet additives: 0.1% sodium lignosulfonate, 0.01% glycerol polyether, 0.3% hydroxyethyl-β-cyclodextrin, 0.5% 1,4-bis (2-Hydroxyethyl)piperazine is added to the deionized water of the remainder, and mixed evenly to make a texture additive;

[0033] (2) Preparation of texturing liquid: prepare 0.4wt% sodium hydroxide aqueous solution in the texturing tank, add the texturing additive in step (1) into the aqueous sodium hydroxide solution at a mass ratio of 1:100 and mix well , to obtain cashmere liquid;

[0034] (3) Texturing: immerse the monocrystalline silicon wafer in the texturing solution prepared in step (2) for surface texturing, the texturing temperature is 83°C, and the texturing time is 7 minutes;

[0035] (4) Cleaning: After washing the monocrystalline silicon wafer that has been textured in step (3), immerse it in a mixed acid ...

Embodiment 2

[0038] The texturing method of monocrystalline silicon chip of the present invention, concrete steps comprise:

[0039] (1) Preparation of velvet additives: 0.2% sodium lignosulfonate, 0.02% glycerol polyether, 0.6% hydroxyethyl-β-cyclodextrin, 1.5% N-(2- Hydroxyethyl) piperazine is added to the deionized water of surplus, mixes and is made into the texture additive;

[0040] (2) Preparation of texturing liquid: Prepare 0.7wt% sodium hydroxide aqueous solution in the texturing tank, add the texturing additive in step (1) into the aqueous sodium hydroxide solution at a mass ratio of 0.8:100 and mix well , to obtain cashmere liquid;

[0041] (3) Texturing: immerse the monocrystalline silicon wafer in the texturing solution prepared in step (2) for surface texturing, the texturing temperature is 83°C, and the texturing time is 7 minutes;

[0042] (4) Cleaning: After washing the monocrystalline silicon wafer that has been textured in step (3), immerse it in a mixed acid containi...

Embodiment 3

[0044] The texturing method of monocrystalline silicon chip of the present invention, concrete steps comprise:

[0045] (1) Preparation of velvet additives: 0.1% sodium lignosulfonate, 0.01% sorbitan, 0.5% carboxymethyl-β-cyclodextrin, 0.8% 1,4- Bis(2-hydroxyethyl)piperazine is added to the remaining amount of deionized water, and mixed evenly to make a texture additive;

[0046] (2) Preparation of texturing liquid: Prepare 0.3wt% sodium hydroxide aqueous solution in the texturing tank, add the texturing additive in step (1) into the aqueous sodium hydroxide solution at a mass ratio of 0.8:100 and mix evenly , to obtain cashmere liquid;

[0047] (3) Texturing: immerse the monocrystalline silicon wafer in the texturing solution prepared in step (2) for surface texturing, the texturing temperature is 83°C, and the texturing time is 7 minutes;

[0048] (4) Cleaning: After washing the monocrystalline silicon wafer that has been textured in step (3), immerse it in a mixed acid cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com