Foundation pit microbial soil gravity type enclosure structure and construction method thereof

A technology of enclosure structure and construction method, applied in the direction of microorganism-based methods, infrastructure engineering, biochemical equipment and methods, etc., can solve the problem of low uniformity of solidified soil, low compressive and shear strength, and poor durability of soil To achieve the effect of slowing down the cementation reaction rate, improving compactness, compression resistance and impermeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

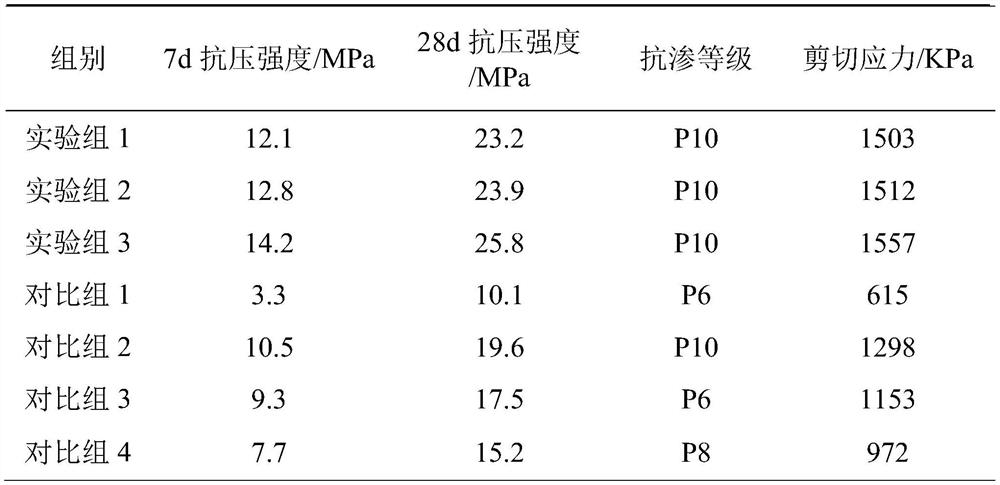

Embodiment 1

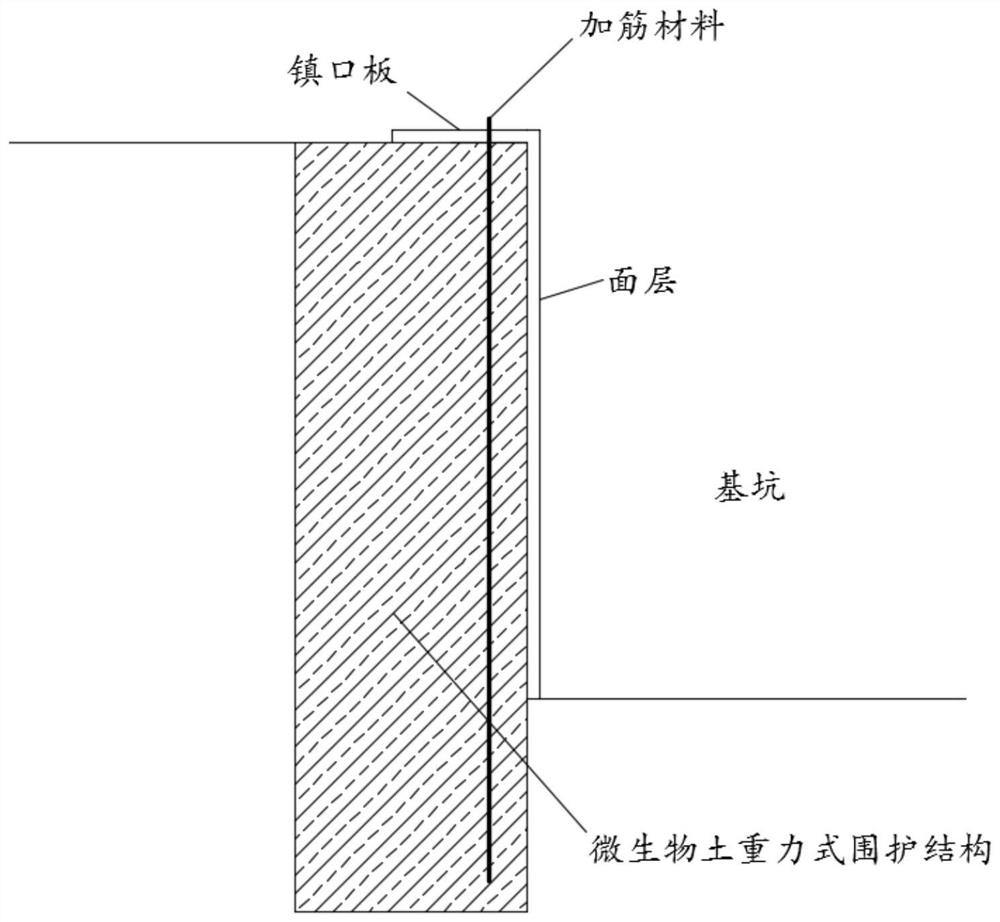

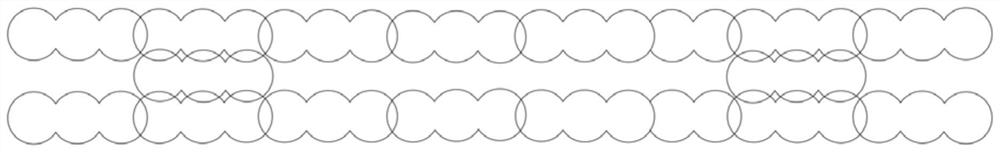

[0031] A microbial soil gravity enclosure structure for a foundation pit, which is mixed with the soil body by a stirring pile machine or a high-pressure jet grouting machine using a composite bacterial solution, a cementing solution, and a solid-carrying material, and then solidified to form a continuous lapped microbial soil column reinforcement Wall; the solid-loaded material is mixed with straw fiber powder and expanded perlite powder with a mass ratio of 7:2;

[0032] The cementing solution includes a concentration of 1.0mol / L calcium chloride solution, 1.0mol / L urea solution and pH=5.5, 0.05mol / L sodium phosphate buffer;

[0033] The composite bacterial solution includes Bacillus pasteurianus with concentration OD600=1.5, Bacillus colii with concentration OD600=0.7 and nutrient salt solution, containing 6.5g soybean peptone, 17g tryptone and 4g soybean meal peptone in every 1L of nutrient salt solution , 5.5g sodium chloride and 20g urea, the pH value of nutrient salt so...

Embodiment 2

[0036]A construction method for a foundation pit microbial soil gravity type enclosure structure, comprising the following steps:

[0037] Step 1: Pile driver positioning, the pile position is determined by the stirring pile driver;

[0038] Step 2: Stir the compound bacterial liquid to sink: the stirring pile driver pours the bacterial liquid and solid-carrying materials, and pre-mixes the compound bacterial liquid and solid-carrying materials during the rotation and sinking process. When the shotcrete port sinks to the design depth, it will Spray the compound bacterial liquid mixture for 60s;

[0039] Wherein, the composite bacterial solution includes Bacillus pasteurianus with concentration OD600=1.3, Bacillus colii with concentration OD600=0.6 and nutrient salt solution, containing 6g soybean peptone, 16g tryptone, 3g soybean meal peptone, 5g sodium chloride and 19g urea, the pH value of nutrient salt solution is 7.2;

[0040] The solid-carrying material is a mixture of ...

Embodiment 3

[0049] A construction method for a foundation pit microbial soil gravity type enclosure structure, comprising the following steps:

[0050] Step 1: Pile driver positioning, the pile position is determined by the high-pressure jet grouting machine;

[0051] Step 2: Stir the composite bacterial solution to sink: the high-pressure jet grouting machine pours the bacterial solution and solid-carrying materials, and pre-mixes the composite bacterial solution and solid-carrying materials during the rotation and sinking process. When the grouting port sinks to the design depth, Spray the compound bacterial liquid mixture on the spot for 70s;

[0052] Wherein, the composite bacteria solution includes Bacillus pasteurianus with concentration OD600=1.5, Bacillus colii with concentration OD600=0.8 and nutrient salt solution, containing 7g soybean peptone, 18g tryptone, 5g soybean meal peptone, 6g sodium chloride and 21g urea, the pH value of nutrient salt solution is 7.3;

[0053] The s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com