Electroplating wastewater treatment system and process

A technology of electroplating wastewater and treatment system, which is applied in metallurgical wastewater treatment, water/sewage treatment, biological water/sewage treatment, etc. It can solve the problems of secondary pollution, adsorbent regeneration, high energy consumption, etc., to avoid pipeline blockage, Reduce the load of water inflow and the effect of no secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

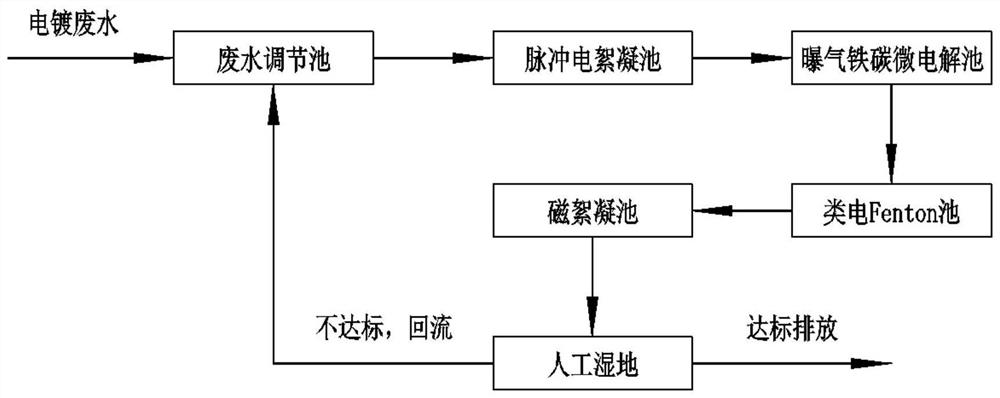

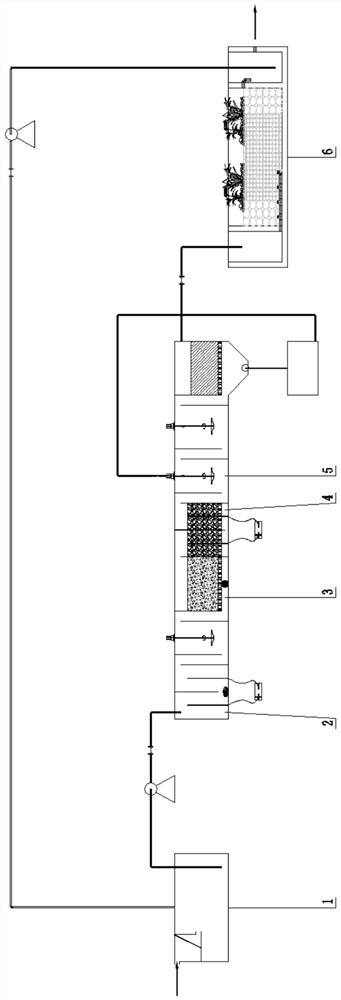

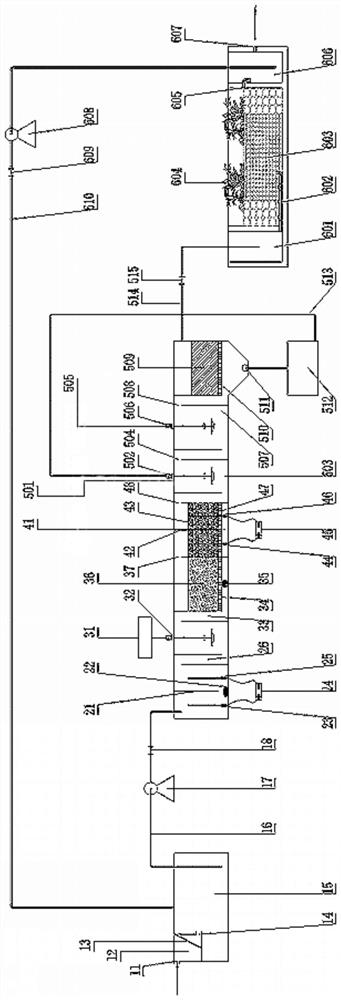

[0102] A system for treating electroplating wastewater, such as figure 2 and image 3 As shown, it includes a regulating tank 1 with a water inlet 11, a pulse electroflocculation tank 2, an aerated iron-carbon internal electrolytic tank 3, a similar electric Fenton tank 4, a magnetic flocculation tank 5 and a constructed wetland 6 with a discharge port 607 .

[0103] Wherein, the regulating pool 1 provided with the water inlet 11 includes the water inlet 11, the grid pool 12, the fine grid net 13, the first water outlet 14, the liquid collection pool 15, the riser 16, the first lift pump 17, the first valve 18;

[0104] The pulse electrocoagulation cell 2 includes a first separator 21, a pulse device 22, a first anode 23, a first stabilized DC power supply 24, a first cathode 25, and a second water outlet 26;

[0105] The aerated iron-carbon internal electrolytic cell 3 includes an acid dosing tank 31, a first agitator 32, a third water outlet 33, a first water guide orifi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com