Fluorine-lined anti-corrosion self-standing regulating valve

A self-supporting, regulating valve technology, applied in the direction of lift valve, valve details, valve device, etc., can solve the problems affecting the service life of the valve, the wear of the valve core and the valve body, and the decline of the valve sealing, so as to enhance the mechanical performance, avoid the Corrosion and excellent wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

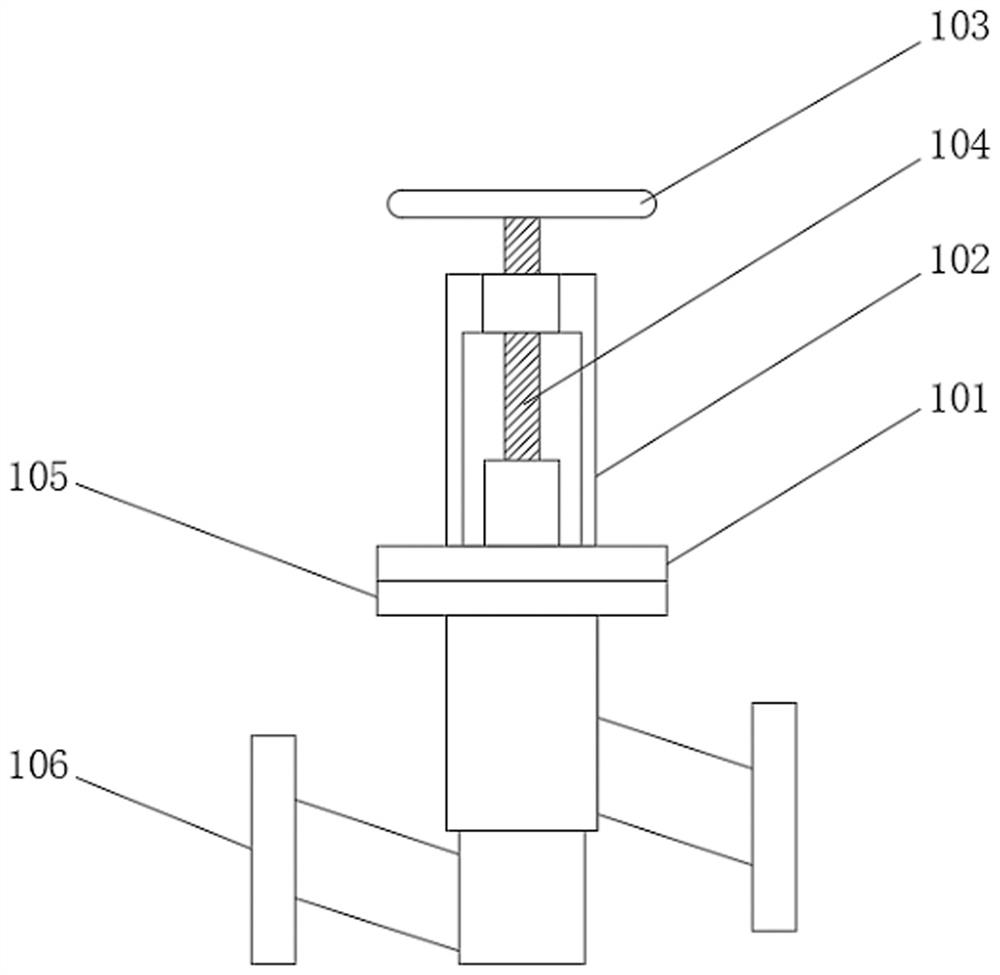

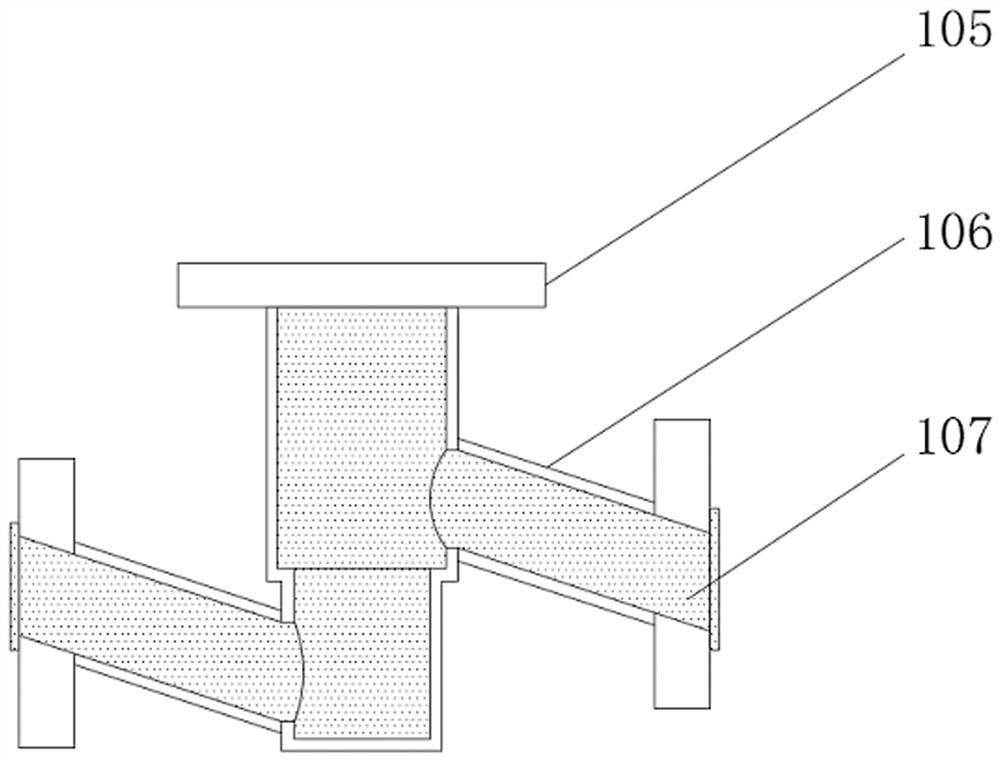

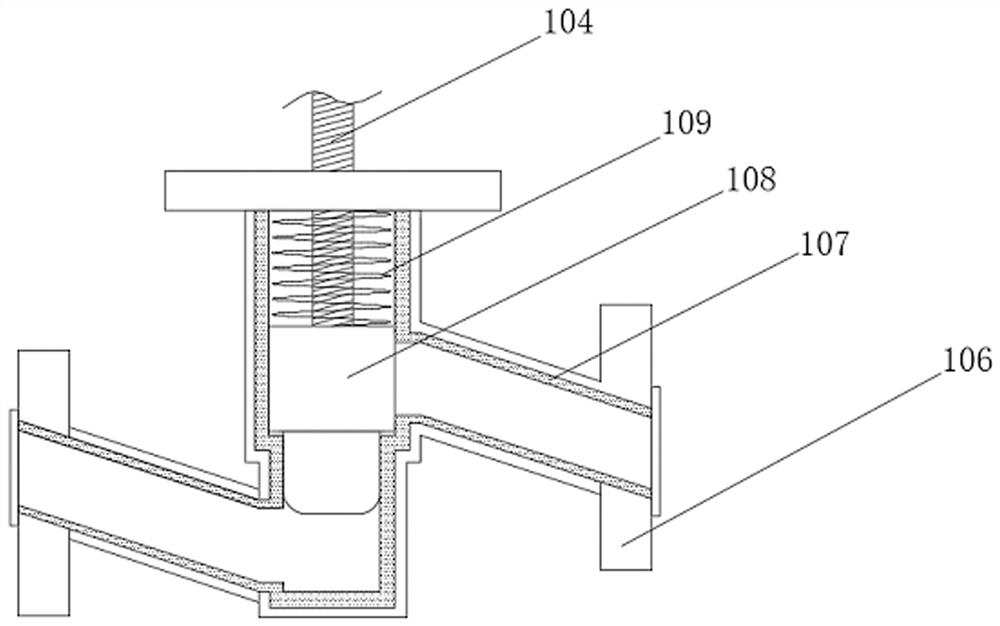

[0037] see Figure 1-3 As shown, this embodiment is a fluorine-lined anti-corrosion self-supporting regulating valve, including a support chassis 101, a mounting frame 102, a turntable 103, a threaded rod 104, a mounting chassis 105, a valve body shell 106, a fluorine-lined inner pipe 107, a lining Fluorine spool 108, back-moving spring 109, the top of described valve body housing 106 is installed with installation chassis 105, and the top of described installation chassis 105 is installed with support chassis 101, and the top of described support chassis 101 is equipped with installation frame 102, so A threaded rod 104 is installed through the mounting frame 102, and the threaded rod 104 is threadedly connected with the mounting frame 102, and a turntable 103 is installed on the top of the threaded rod 104;

[0038] A fluorine-lined inner tube 107 is installed inside the valve housing 106, a fluorine-lined valve core 108 is slidably connected to the inner cavity of the fluor...

Embodiment 2

[0042] Present embodiment is a kind of preparation process of modified polytetrafluoroethylene, comprises the following steps:

[0043] A1: Add carbon tetrachloride, catalyst and deionized water into the reactor, then add hexafluoropropylene oxide into the reactor at a temperature of 15°C, and stir at a constant temperature at a stirring rate of 50r / min Reaction for 30 minutes, after the reaction, the reaction product was left to stand for stratification, the lower layer was rectified, and the fraction at 54°C was collected to obtain an intermediate product; the moles of carbon tetrachloride, catalyst, deionized water, and hexafluoropropylene oxide were controlled The ratio is 5:0.25:0.06:10, and the catalyst is cesium chloride;

[0044] A2: Add anhydrous sodium carbonate and dimethylacetamide to the reaction kettle, stir and mix for 5 minutes at a stirring rate of 50r / min, then add the intermediate product and continue to stir for 30 minutes, and then mix at a temperature of ...

Embodiment 3

[0047] Present embodiment is a kind of preparation process of modified polytetrafluoroethylene, comprises the following steps:

[0048] A1: Add carbon tetrachloride, catalyst and deionized water into the reactor, then add hexafluoropropylene oxide into the reactor at a temperature of 20°C, and stir at a constant temperature at a stirring rate of 150r / min React for 60 minutes. After the reaction, the reaction product is left to stand for stratification, the lower layer is rectified, and the fraction at 56 ° C is collected to obtain an intermediate product; the moles of carbon tetrachloride, catalyst, deionized water, and hexafluoropropylene oxide are controlled The ratio is 5:0.25:0.06:10, and the catalyst is tetramethylethylenediamine;

[0049] A2: Add anhydrous sodium carbonate and dimethylacetamide into the reaction kettle, stir and mix for 10min at a stirring rate of 100r / min, then add the intermediate product and continue stirring for 60min, and then mix at a temperature o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com