Application of sodium glucoheptonate in tin-iron flotation separation

A technology of sodium glucoheptonate and tin iron, which is applied in flotation, solid separation, etc., can solve the problems of rare technologies, achieve high adaptability and expand the effect of flotation property difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1、2、3

[0029] Embodiments 1, 2, and 3 merge the tables as follows according to the experimental situation:

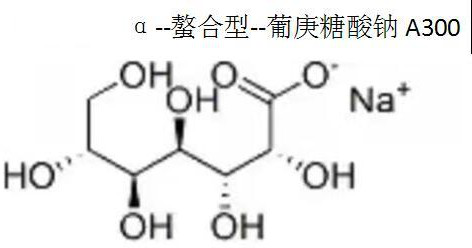

[0030] The applicant unit combined production and scientific experiments, through years of continuous search and screening, finally found an organic acid salt substance with a carboxylic acid group that can inhibit iron oxide, which is the α-isomer of sodium glucoheptonate. The experiment uses tin-iron symbiotic oxide ore in the Gejiu tin mine area of Yunnan. The target mineral is cassiterite, the main gangue mineral is hematite, and calcium oxide ore. First, grind and dissociate the mineral raw materials to -300 mesh, use a 1L flotation machine to go through a rough sweep and two sweeps, and use this inhibitor. The rest of the experimental conditions are as follows: the regulator is sulfuric acid, the foaming agent is 730A, the rough selection is 8 minutes, the first sweep is 6 minutes, the second sweep is 5 minutes, the stirring intensity is 1200 rpm, and the order of admi...

Embodiment 4

[0036] Although pyrogallol, as a phenolic inhibitor, can strongly inhibit iron-calcium minerals in the separation of tin and iron, it is expensive and difficult to implement in production. The inventors found out that alpha-type sodium glucoheptonate A300 is used in production as a cheaper medicament than pyrogallol, and the cost is feasible, so for the same batch of materials containing 1.02% and 1.08% tin slime (the same Batch slime) test, and the test comparison of tailings containing 0.57% tin to verify its ability to inhibit iron minerals. The inhibitor is high-viscosity carboxymethyl cellulose and sodium humate, the regulator is sulfuric acid, the foaming agent is 730A, the roughing is 8 minutes, the first sweep is 6 minutes, the second sweep is 5 minutes, and the stirring intensity is 1200 rpm Every minute, the order of dosing is ~ first add sulfuric acid to adjust the pH value to ensure 6-6.5 (between 50 ~ 54mv potential), add ∝ ~ sodium glucoheptonate A300, then add c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com