Method for synthesizing dimethyl carbonate and co-producing ethylene glycol by coupling CO2

A technology of dimethyl carbonate and ethylene glycol, which is applied in the field of coupling CO2 to synthesize dimethyl carbonate and co-produce ethylene glycol, which can solve the problems of high water consumption, low carbon utilization efficiency, and large carbon dioxide emissions, so as to avoid environmental pollution. Pollution, carbon emission reduction, and productivity improvement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

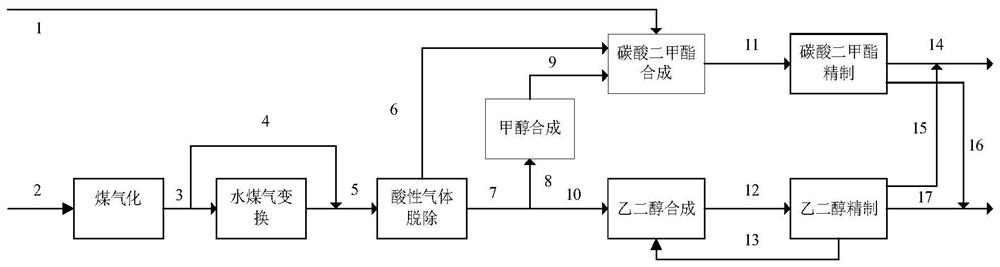

[0038] Such as figure 1 As shown, this embodiment couples the CO 2 The method for synthesizing dimethyl carbonate co-production ethylene glycol may further comprise the steps:

[0039] S1: Raw coal gasification to produce crude synthesis gas

[0040] After the dried raw coal is pulverized and sieved, the gasification reaction is carried out (high temperature 1300-1500°C, pressure 2.7-6.5MPa, oxygen as gasification agent), and H 2 , CO and CO 2 The main crude synthesis gas (the H in the crude synthesis gas 2 The molar ratio to CO is between 0.3 and 0.8).

[0041] S2: Water-gas shift of crude synthesis gas

[0042] A part of the crude synthesis gas prepared in step S1 is subjected to water-gas shift to make CO and H 2 O reacts to form H 2 and CO 2; The crude synthesis gas after the water-gas shift is merged with the remaining crude synthesis gas that has not been subjected to the water-gas shift to obtain the crude synthesis gas after the hydrogen-carbon ratio is regulat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com