Device and method for treating organic waste gas by coupling ultraviolet light catalysis with microorganisms

A technology for microbial treatment and organic waste gas, applied in chemical instruments and methods, chemical/physical processes, separation methods, etc., can solve the difficulty of biological treatment of organic pollutants, the loss of advantages of advanced oxidation-biodegradation, and the difficulty in controlling intermediate products. and other problems, to achieve the effect of shortening the processing cycle, compact structure and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

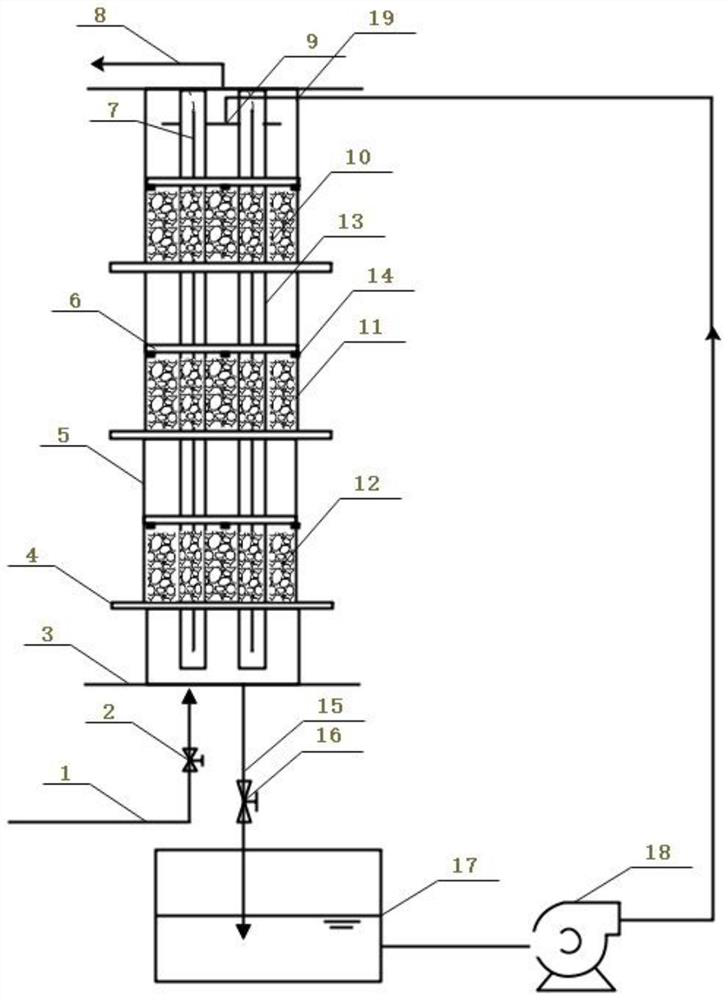

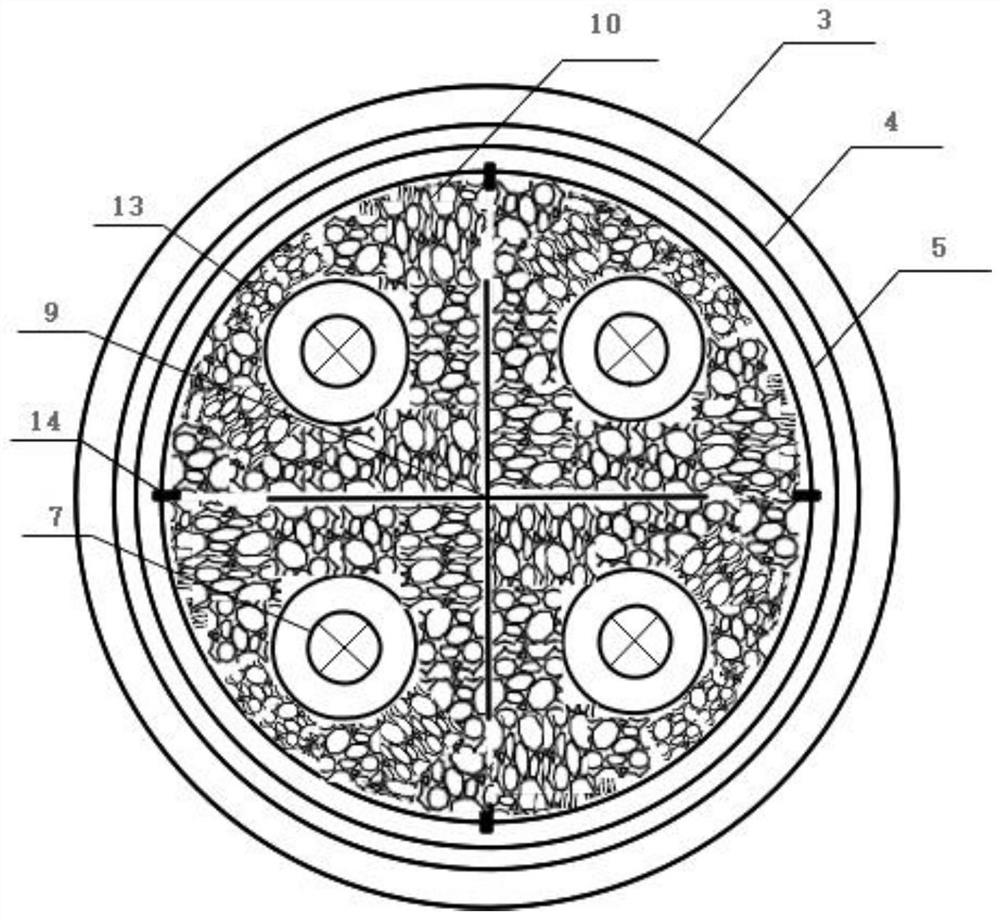

[0033] like figure 1 , figure 2 As shown, a device for treating organic waste gas with ultraviolet photocatalytic coupling microorganisms of the present invention includes an ultraviolet photocatalytic coupling microbial reactor, a circulating liquid storage tank 17 and a circulation pump 18, and the ultraviolet photocatalytic coupling microbial reactor includes a housing 5. The housing 5 is made of plexiglass, the bottom of the housing 5 is provided with an air inlet 1 and a liquid outlet 15, and the top of the housing 5 is provided with an air outlet 8 and a liquid inlet 19. The upper part of the casing 5 is also provided with a spraying device 9, which communicates with the liquid inlet 19. The spraying device 9 in this embodiment is preferably cross-shaped, and the spraying is more uniform.

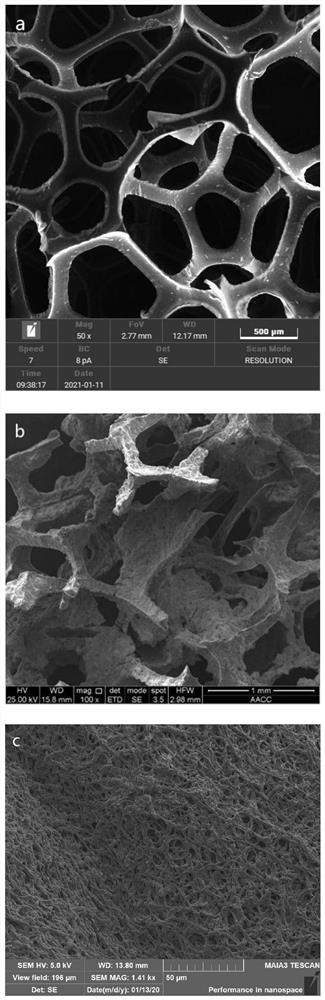

[0034]The inside of the housing 5 is provided with at least two filler layers sequentially from bottom to top, and the filler layers are loaded with highly efficient degrading bacte...

Embodiment 2

[0053] Utilize the treatment device of embodiment 1 to carry out chlorobenzene waste gas treatment, set only ultraviolet light irradiation as control group, experimental group is set to ultraviolet+Ag / WO 3 (UV Photocatalytic Oxidation), UV+Efficient Degrading Bacteria (Biodegradation), UV+Ag / WO 3 +Efficient degrading bacteria (UV photocatalytic oxidation-biological direct coupling).

[0054] The circulating fluid flow rate is 2.95×10 -5 m 3 / s, the column temperature is kept at 25°C, the empty bed residence time (EBRT) is controlled at 120s, and the initial concentration of chlorobenzene is 160mg / m 3 Under the condition of reaction 10h, the concentration of chlorobenzene in the control group basically did not change.

[0055] From 0 to 4 hours, the concentration of chlorobenzene in the experimental group loaded with biofilm almost did not decrease. After 4 hours of adaptation, the degradation effect of biofilm on chlorobenzene increased slowly.

[0056] UV+Ag / WO 3 The deg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com