Oxidized hyperbranched polyethyleneimine nanofiltration membrane, preparation method and application

A polyethyleneimine sodium and polyethyleneimine technology, which is applied in the field of preparation and oxidation of hyperbranched polyethyleneimine nanofiltration membranes, can solve the problems of difficult industrial production and cannot meet the requirements of green chemistry, etc., and achieves huge application potential and conditions. Mild effect with simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

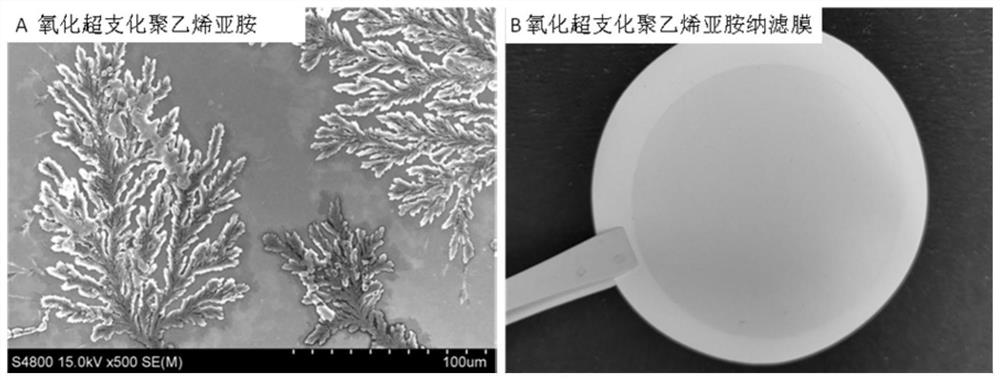

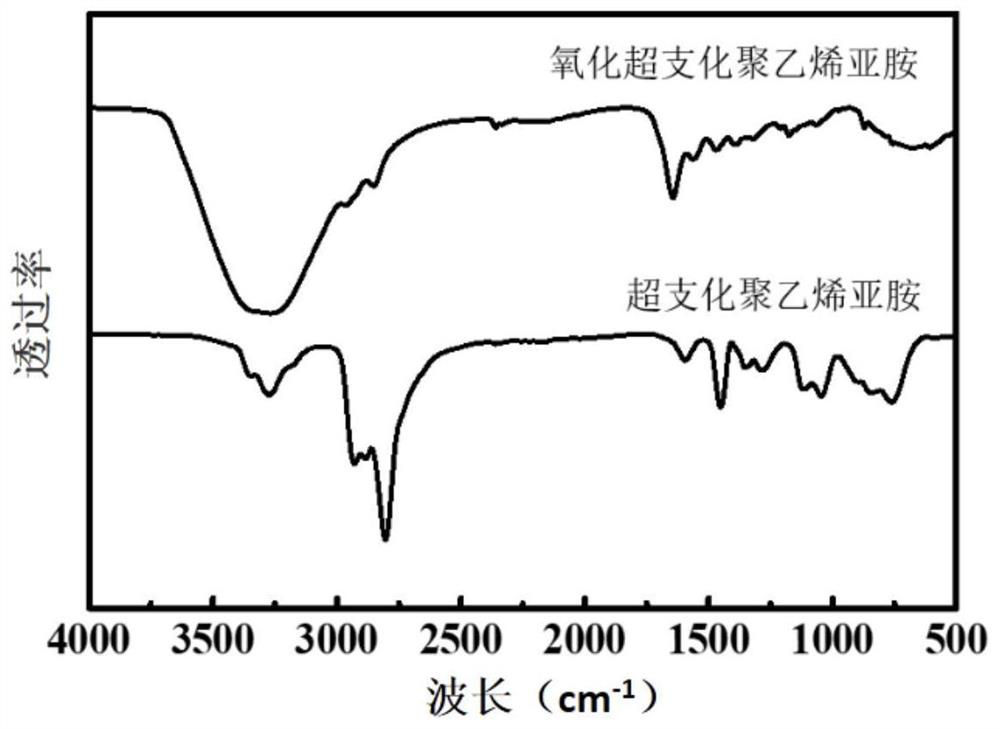

[0037] Take 25 mg of hyperbranched polyethyleneimine with a molecular weight of 1800 Da, dissolve it in 5 mL of deionized water, and stir evenly to obtain an aqueous solution of hyperbranched polyethyleneimine, then add 0.5 mL of 30 wt % hydrogen peroxide to it, and react at 25 ° C for 3 h. After precipitation was precipitated in the above reaction system, 30 mL of deionized water was added to dilute to obtain a suspension of oxidized hyperbranched polyethyleneimine. Among them, the oxidized hyperbranched polyethyleneimine precipitated in the reaction system was light yellow, and the microscopic appearance was as follows: figure 1 As shown in A.

[0038]A mixed cellulose microfiltration membrane with a pore size of 0.1 μm is used as a support layer, and the suspension of oxidized hyperbranched polyethyleneimine is placed on the support layer and vacuum-filtered to form a membrane at a vacuum degree of 0.05 MPa, and dried at 45°C for 2 hours to obtain Oxidized hyperbranched po...

Embodiment 2

[0046] Take 25 mg of hyperbranched polyethyleneimine with a molecular weight of 10000 Da, dissolve it in 5 mL of deionized water, and stir evenly to obtain an aqueous solution of hyperbranched polyethyleneimine, then add 2 mL of 30 wt % hydrogen peroxide to it, and react at 25 ° C for 3 h, and wait for the above After precipitation in the reaction system, add 30 mL of deionized water to dilute to obtain a suspension of oxidized hyperbranched polyethyleneimine.

[0047] Using a mixed cellulose microfiltration membrane with a pore size of 0.1 μm as a support layer, place the suspension of oxidized hyperbranched polyethyleneimine on the support layer and vacuum filter it to form a membrane. Hyperbranched polyethyleneimine nanofiltration membrane.

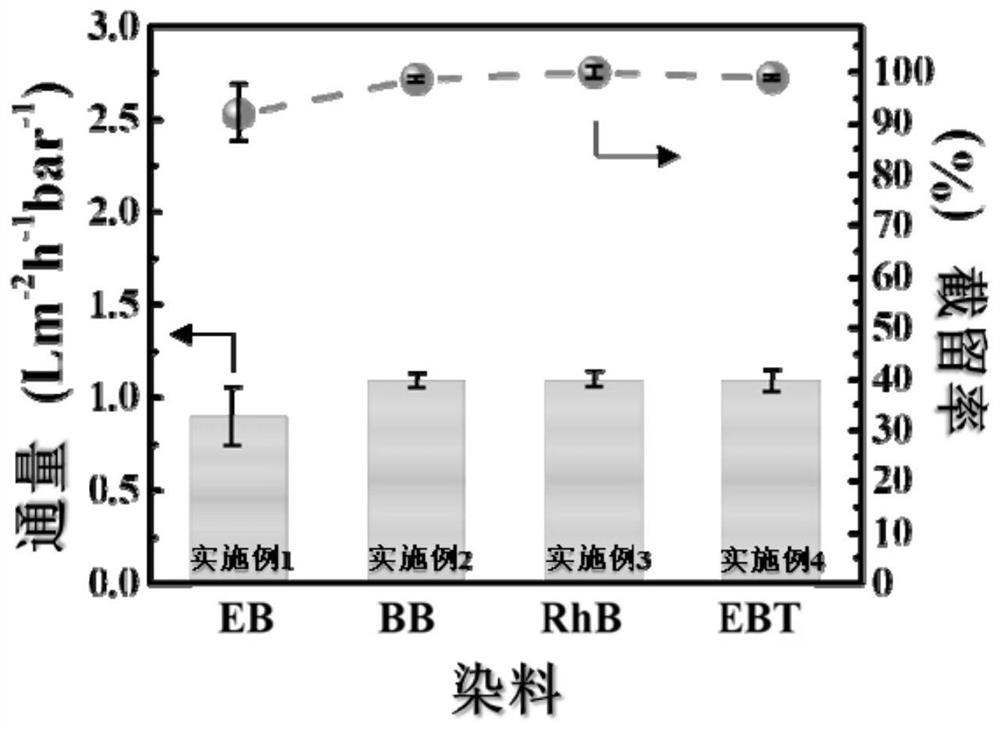

[0048] Under the pressure of 4bar, the brilliant blue (BB) solution of 50mg / L is separated by the oxidized hyperbranched polyethyleneimine film that obtains, and the result is as follows image 3 As shown, the flux is 1.1L m -2 h -1...

Embodiment 3

[0050] Take 25 mg of hyperbranched polyethyleneimine with a molecular weight of 600 Da, dissolve it in 5 mL of deionized water, and stir evenly to obtain an aqueous solution of hyperbranched polyethyleneimine, then add 1 mL of chemically pure sodium hypochlorite to it, and react for 2 minutes at 25 ° C, wait for the above reaction After precipitation in the system, add 30 mL of deionized water to dilute to obtain a suspension of oxidized hyperbranched polyethyleneimine.

[0051] Using a mixed cellulose microfiltration membrane with a pore size of 0.1 μm as a support layer, place the suspension of oxidized hyperbranched polyethyleneimine on the support layer and vacuum filter it to form a membrane. Hyperbranched polyethyleneimine nanofiltration membrane.

[0052] Under the pressure of 4bar, the rhodamine B (RhB) solution of 50mg / L is separated by the oxidized hyperbranched polyethyleneimine membrane that obtains, and the result is as follows image 3 As shown, the flux is 1.2L...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com