Continuous glass fiber reinforced polyurethane foam material forming process and system

A continuous glass fiber and foam material technology, applied in the field of polyurethane composite material preparation, can solve the problems affecting the mechanical properties of products, the inability to obtain reinforced polyurethane microcellular foam profiles, and high glass fiber density, and achieve the effect of full infiltration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

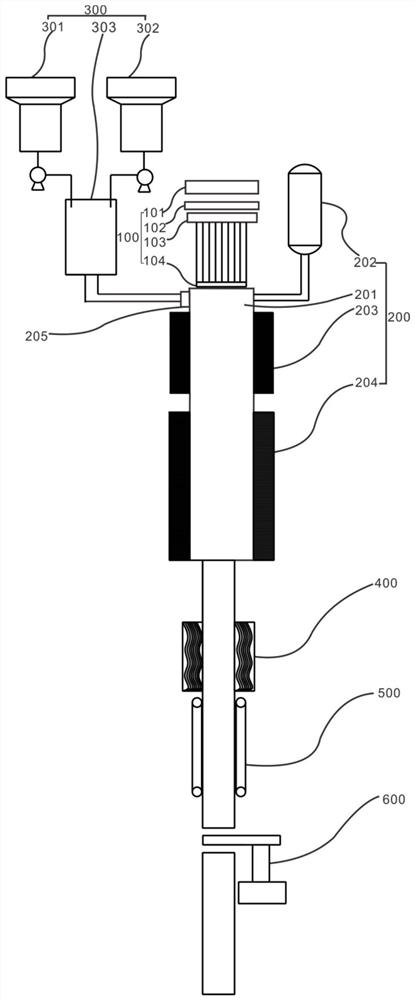

Image

Examples

Embodiment 1

[0050] (1) Preparation of matrix raw materials: The weight parts of each raw material in the foaming system are calculated according to the following ratio to prepare the combined polyether, and after fully mixing, add it to the A storage tank;

[0051]

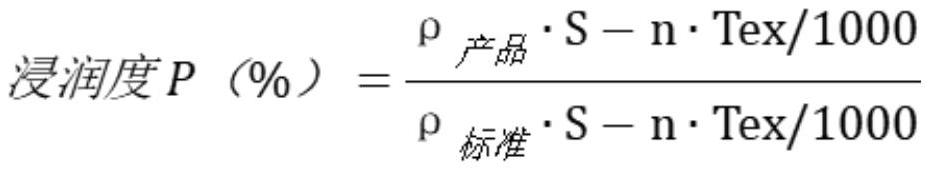

[0052] The formula for calculating the wettability of combined polyether is as follows:

[0053]

[0054] Among them, ρ 产品 is the density of the experimental product, ρ 标准 is the density of the standard product, S is the cross-sectional area of the shaped product, n is the number of strands of glass fiber, and Tex is the mass of 1000m per strand of glass fiber;

[0055] The degree of infiltration of the combined polyether is calculated to be 99%;

[0056] The viscosity of the combined polyether is 300mPa.s at 40°C, and the average functionality is 3.2;

[0057] At the same time, isocyanate is added in storage tank B, wherein isocyanate is 105 parts of diphenylmethane diisocyanate (MDI)

[0058] (2) Reinforcement m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com