Dry-mixed self-leveling mortar

A self-leveling mortar and dry-mixing technology, applied in the field of building materials, can solve problems such as complex operation, sanding, and loss of surface flatness of self-leveling mortar

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

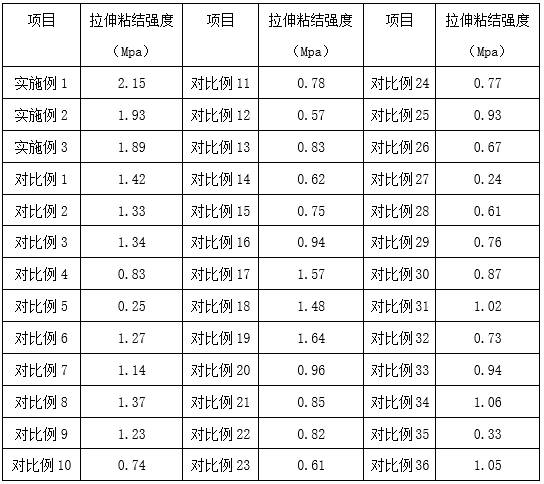

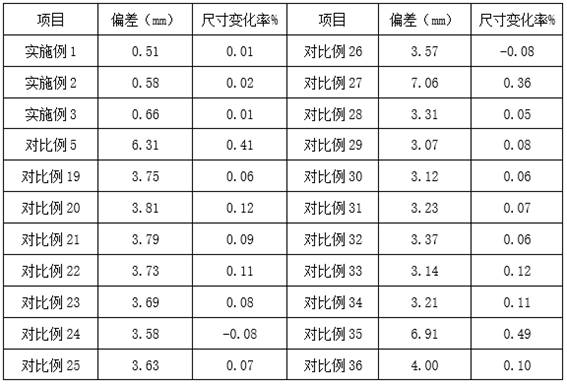

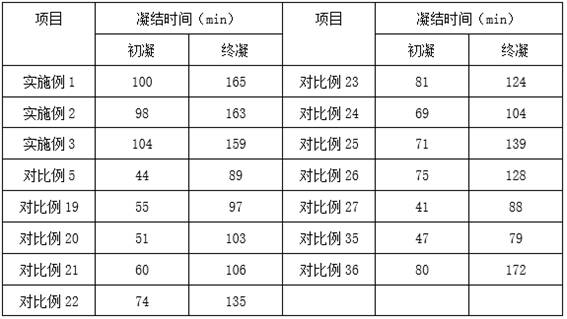

Examples

Embodiment 1

[0041] A dry-mixed self-leveling mortar, raw materials include P.O42.5 cement: 310 parts, high alumina cement: 160 parts, 100 mesh machine-made sand: 425 parts, heavy calcium: 155 parts, gray calcium: 18 parts, cellulose ether 100,000: 2 parts, rubber powder 4109: 13 parts, defoamer 361: 2 parts, water-repellent agent 780: 3 parts, polycarboxylate superplasticizer 315: 2 parts, calcium formate: 7 parts, lithium carbonate 1.5 parts 2 parts, 2 parts of tartaric acid, 2 parts of modified retarder, 2.5 parts of modified leveling agent.

[0042] Wherein, the machine-made sand is mixed sand with a mass ratio of 100 mesh basalt sand: 100 mesh quartz sand: 100 mesh modified glass sand in a mass ratio of 4:5:3.

[0043] The preparation method of described modified glass sand is:

[0044] 1) Cleaning: Clean waste glass products to remove soil impurities and metal residues on the surface, then soak them in a hydrochloric acid solution with a pH of 4.8 for 10 hours, and then clean them f...

Embodiment 2

[0067] A dry-mixed self-leveling mortar, raw materials include P.O42.5 cement: 300 parts, high alumina cement: 170 parts, 80 mesh machine-made sand: 450 parts, heavy calcium: 160 parts, ash calcium: 15 parts, cellulose ether 100,000: 3 parts, rubber powder 4109: 12 parts, defoamer 361: 3 parts, water-repellent agent 780: 4 parts, polycarboxylate superplasticizer 315: 1 part, calcium formate: 5 parts, lithium carbonate 1 3 parts, tartaric acid 3 parts, modified retarder 3 parts, modified leveling agent 2 parts.

[0068] Wherein, the machine-made sand is mixed sand with a mass ratio of 80 mesh basalt sand: 120 mesh quartz sand: 80 mesh modified glass sand in a mass ratio of 4:5:3.

[0069] The preparation method of described modified glass sand is:

[0070] 1) Cleaning: Clean waste glass products to remove soil impurities and metal residues on the surface, then soak them in a hydrochloric acid solution with a pH of 4.5 for 10 hours, and then clean them for later use;

[0071] ...

Embodiment 3

[0093] A dry-mixed self-leveling mortar, raw materials include P.O42.5 cement: 320 parts, high alumina cement: 150 parts, 120 mesh machine-made sand: 400 parts, heavy calcium: 150 parts, ash calcium: 20 parts, cellulose ether 100,000: 1 part, rubber powder 4109: 15 parts, defoamer 361: 1 part, water repellent 780: 2 parts, polycarboxylate superplasticizer 315: 3 parts, calcium formate: 8 parts, lithium carbonate 2 1 part, 1 part of tartaric acid, 1 part of modified retarder, 3 parts of modified leveling agent.

[0094] Wherein, the machine-made sand is mixed sand with a mass ratio of 120 mesh basalt sand: 80 mesh quartz sand: 120 mesh modified glass sand in a mass ratio of 4:5:3.

[0095] The preparation method of described modified glass sand is:

[0096] 1) Cleaning: Clean waste glass products to remove soil impurities and metal residues on the surface, then soak them in a hydrochloric acid solution with a pH of 5.0 for 10 hours, and then clean them for later use;

[0097]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com