Preparation method of hydrophobic degradable starch nano composite film and obtained product

A starch nano-composite film technology, applied in the field of new functional materials, can solve problems such as poor hydrophobicity and poor mechanical properties, and achieve the effects of improved mechanical properties, high concentration of production capacity, and abundant supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] (1) Dissolve 2 g of cornstarch in 70 ml of ultrapure water, heat and stir in a magnetic stirrer at about 60°C for 30 minutes to obtain a uniform turbid liquid, transfer the turbid liquid to a high-pressure reaction kettle, and heat at 180°C The lower seal was hydrothermally reacted for 8 h to obtain a turbid hydrothermal starch carbon nanosphere solution (hereinafter referred to as the pretreatment solution), which was cooled for later use.

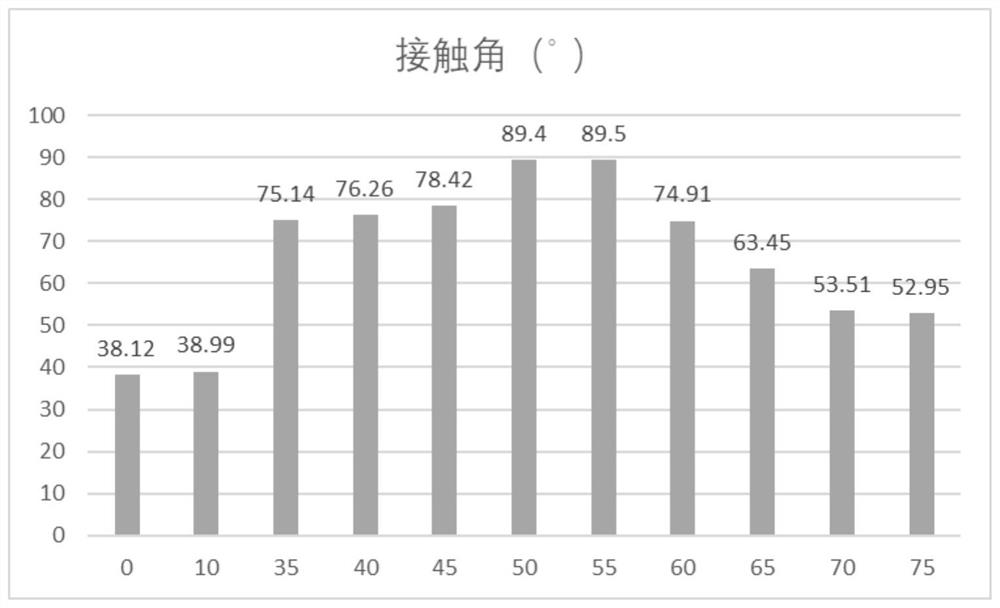

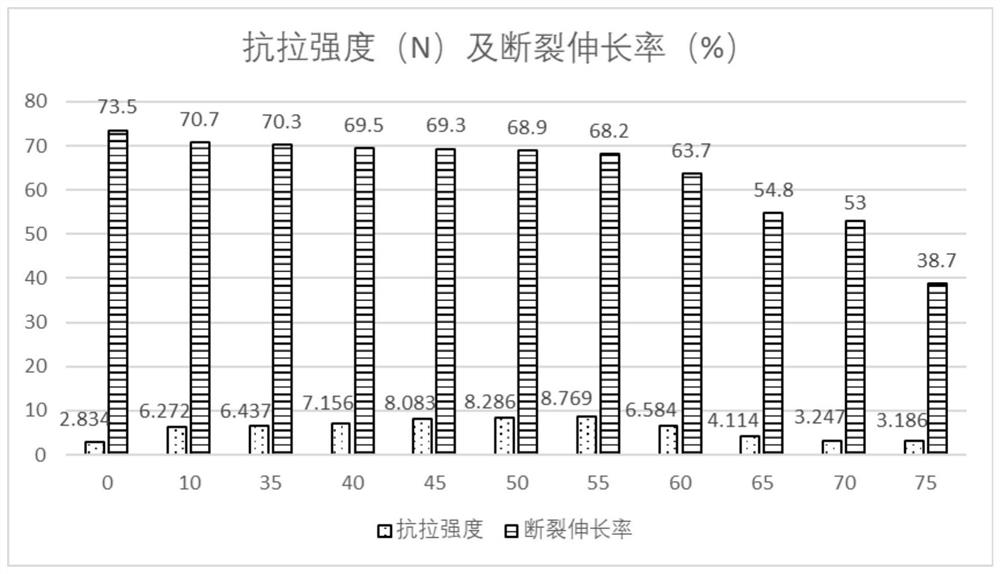

[0044] (2) Dissolve 5g of cornstarch and 2.0g of glycerin in 80g of ultrapure water, pour the resulting mixture into a beaker, seal the mouth of the beaker with a film and insert it (the aperture should not be too large or too small), and heat it at about 97 °C After stirring in a magnetic stirrer for 1 hour, add 0 ml, 10 ml, 35 ml, 40 ml, 45 ml, 50 ml, 55 ml, 60 ml, 65 ml, 70 ml, and 75 ml of cooled pretreatment solution, Stirring was continued for 1 h in a magnetic stirrer at around 97 °C.

[0045] (3) Pour the mixed solution in...

Embodiment 2

[0051] (1) According to the method of Example 1, a hydrothermal starch carbon nanosphere solution (hereinafter referred to as the pretreatment solution) was prepared.

[0052] (2) Dissolve 5 g of cornstarch and 2.0 g of glycerin in 80 g of ultrapure water, pour the resulting mixture into a beaker, seal the mouth of the beaker with a film and insert it (the aperture should not be too large or too small), and put it at 97 °C Stir for 1 h on a left and right magnetic stirrer.

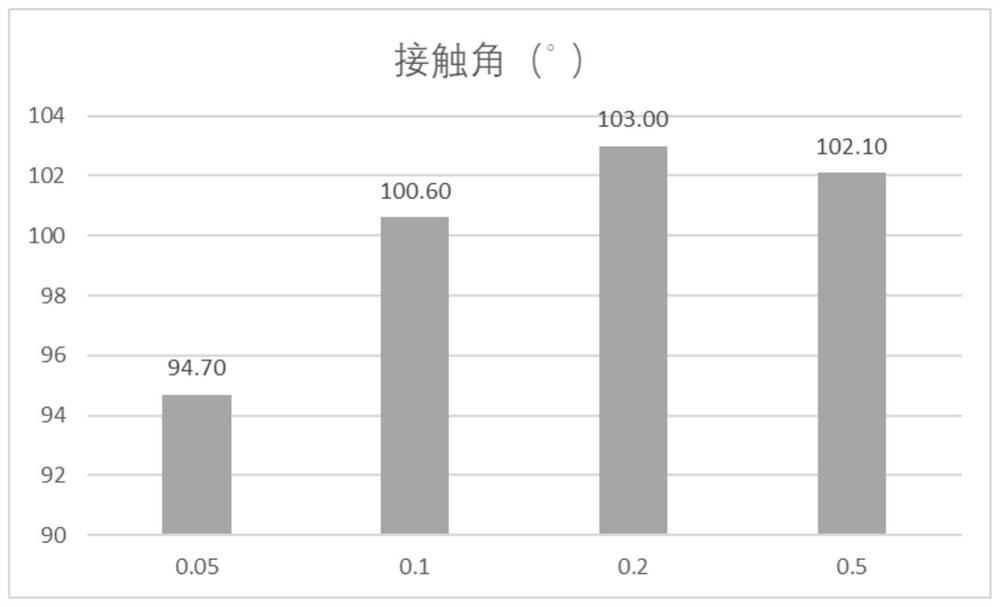

[0053] (3) Mix 55 ml of the pretreatment solution cooled in step (1) with 0.05 g, 0.1 g, 0.2 g, and 0.5 g of nano-calcium carbonate soaked in absolute ethanol respectively, and disperse the nano-calcium carbonate after 30 min of ultrasonic dispersion. Evenly dispersed in the pretreatment solution.

[0054] (4) Pour the mixed liquid that has been sonicated in step (3) into the beaker in step (2), and continue to stir in a magnetic stirrer at about 97 °C for 1 h.

[0055] (5) Pour the mixed solution in (4)...

Embodiment 3

[0061] (1) Prepare a hydrothermal carbon nanosphere solution (hereinafter referred to as pretreatment solution) according to the method in Example 1.

[0062] (2) Dissolve 5g of cornstarch in 80g of ultrapure water, then add 1.5g, 1.8g, 2.0g, and 2.5g of glycerin respectively, pour the resulting mixture into beakers, seal the mouth of the beaker with film too large or too small), after stirring for 1 hour in a magnetic stirrer at a temperature of about 97°C, add 55ml of the solution in step (1) to take out the cooled pretreatment solution in the autoclave. Stirring was continued for 1 h in a magnetic stirrer at around °C.

[0063] (3) Pour the mixed solution in (2) over the gauze and pour it on the template, and dry it in a blast drying oven at 35°C for 8 hours to prepare a starch nanocomposite film starch film with a thickness of 0.13-0.18 mm.

[0064] The contact angle, tensile strength, elongation at break and water permeability coefficient of the composite films obtained ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com