A kind of photocatalytic self-cleaning composite coating and preparation method thereof

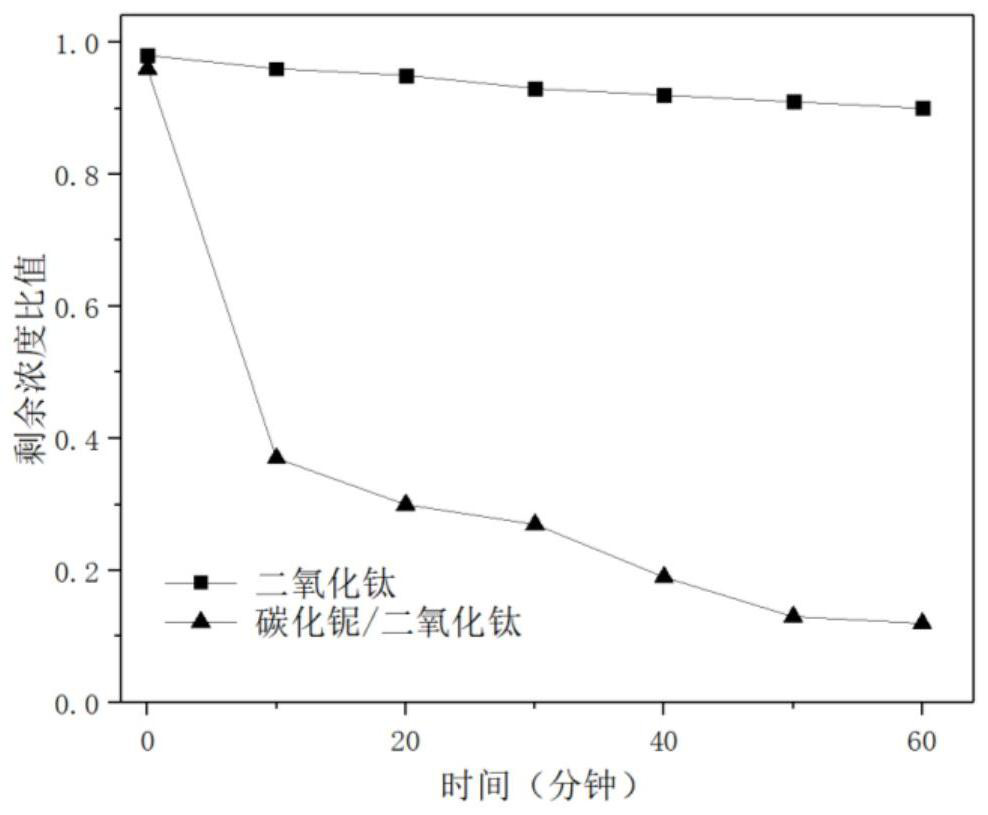

A composite coating and self-cleaning technology, applied in the direction of conductive coatings, coatings, etc., can solve the problems of coatings with no self-cleaning materials, achieve excellent photocatalytic treatment effects, improve photocatalytic ability, and enhance photocatalytic activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Using 1g of niobium aluminum carbide as a precursor, stir vigorously at a temperature of 35°C in 10mL of 40% hydrofluoric acid solution to obtain niobium carbide;

[0031] (2) Transfer the obtained niobium carbide to 10 mL of isopropylamine solution, stir vigorously for 24 hours to intercalate niobium carbide to obtain niobium carbide single-layer nanosheets, and wash off the intercalation agent with deionized water several times after the reaction until The pH of the supernatant is 3-4, add deionized water to a constant volume of 100mL, centrifuge at 3500rpm for 60min to obtain a stable colloidal solution;

[0032] (3) The selected co-solvent isopropanol 5mL, 2mL niobium carbide single-layer nanosheet colloidal solution, 4mL 5wt% titanium dioxide solution, and 20mL tetraethyl orthosilicate are mixed, and the tetraethyl orthosilicate is carried out at a temperature of 25°C and a rotation speed of 300rpm. Hydrolysis reaction;

[0033] (4) Add 12mL of ethanol, 8mL of...

Embodiment 2

[0039] (1) The niobium carbide single-layer nanosheet / titanium dioxide photocatalytic self-cleaning composite coating was prepared in the same manner as in Example 1.

[0040] (2) Use a spray gun to evenly spray the photocatalytic self-cleaning composite coating obtained above on a 30cm*30cm tempered glass under the condition of an air compressor pressure of 0.5-0.6MPa, and let it dry naturally for 24 hours.

[0041] (3) Remove the co-solvent isopropanol in the production process of the niobium carbide single-layer nanosheet / titanium dioxide photocatalytic self-cleaning composite coating, and spray it on the tempered glass as a control group and dry it in the same way.

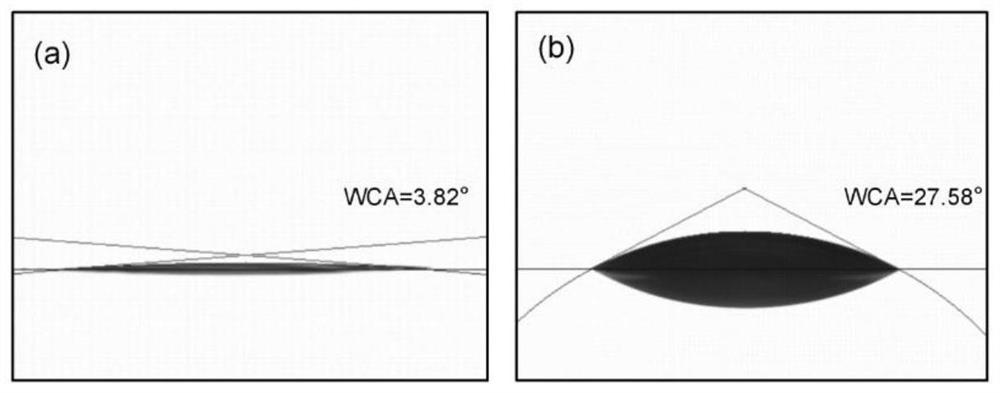

[0042] (4) The water contact angle of the tempered glass surface sprayed with niobium carbide single-layer nanosheet / titanium dioxide photocatalytic self-cleaning composite coating was measured by a contact angle measuring instrument. figure 2 (a), the water contact angle is 3.82°, demonstrating the superhydr...

Embodiment 3

[0044] (1) Niobium carbide monolayer nanosheets were prepared in the same manner as in Example 1.

[0045] (2) Divide the niobium carbide single-layer nanosheets into two parts. After the reaction, one part is centrifuged with deionized water to wash off the intercalation agent until the pH of the supernatant is 3-4, and then add deionized water to constant volume. 50mL was centrifuged at 3500rpm for 60min to obtain a stable colloidal solution; the other was used as a control group, without washing the intercalation agent, directly added to 50mL of deionized water, and centrifuged at 3500rpm for 60min to obtain a stable colloidal solution.

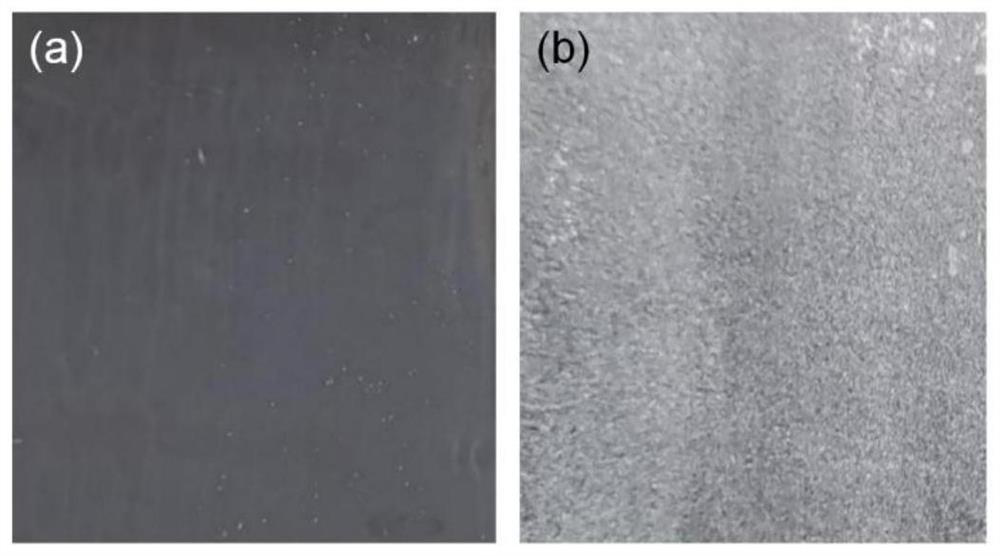

[0046] (3) The selected co-solvent isopropanol 5mL, 2mL niobium carbide single-layer nanosheet colloidal solution, 4mL 5wt% titanium dioxide solution, and 20mL tetraethyl orthosilicate are mixed, and the tetraethyl orthosilicate is carried out at a temperature of 25°C and a rotation speed of 300rpm. Hydrolysis reaction: mix the same 2mL co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com