Ultraviolet curing color glue and preparation method thereof

A technology of ultraviolet light and color glue, applied in the direction of adhesives, non-polymer adhesive additives, adhesive types, etc., can solve the problems of weak hardness and acid resistance, and can not make thickness, etc., to achieve easy processing and increase the cost The effect of improving production efficiency and improving space utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

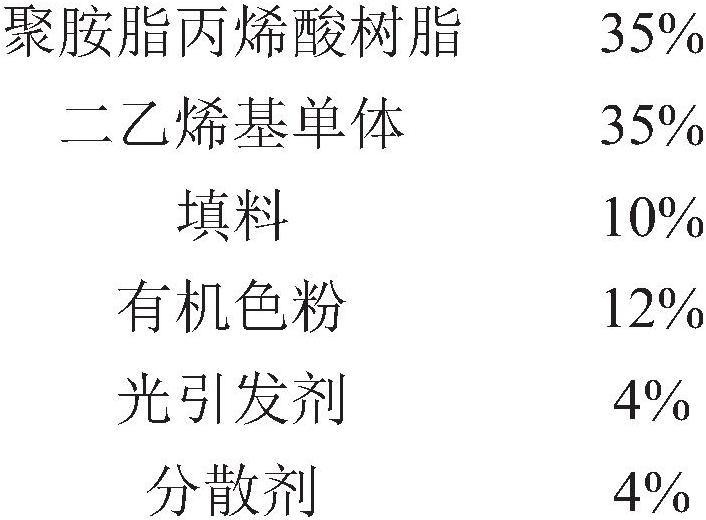

[0032] Deploying UV-curable color glue, including the following components in mass percentage:

[0033]

[0034] Wherein, the filler is: aluminosilicate (aluminum oxide: silicon oxide = 1: 1); the photoinitiator is: triarylsulfonium hexafluorophosphate; the dispersant is acrylate and polyurethane (the mass accounts for 50% each); The organic toners are light fast red (red) and permanent yellow (yellow), which are respectively used as the positive and negative colors of the battery.

[0035] Take the overall 100g as the unit, add the amount of each component according to the above ratio, and prepare the special light-curing integrated color glue:

[0036] (1) Gradually add a dispersant to the divinyl monomer, and the stirring speed is controlled at 400 rpm;

[0037] (2) Add the divinyl monomer that has added the dispersant obtained in step (1) in the polyurethane acrylic resin, and the stirring speed is controlled at 200 revolutions / min; the viscosity of the main body mater...

Embodiment 2

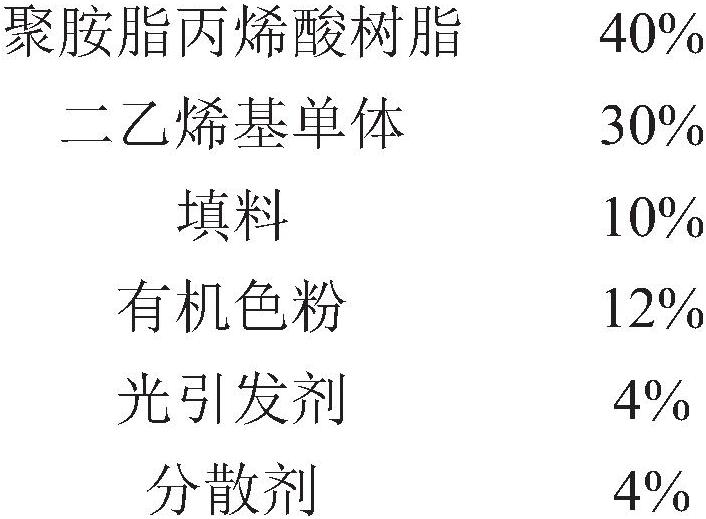

[0042] Deploying UV-curable color glue, including the following components in mass percentage:

[0043]

[0044] Wherein, the filler is: aluminosilicate (aluminum oxide: silicon oxide = 1: 1); the photoinitiator is: triaryl sulfonium hexafluorophosphate; the dispersant is acrylate and polyurethane (each accounting for 50% by mass); The organic toners are light fast red (red) and permanent yellow (yellow), which are respectively used as the positive and negative colors of the battery.

[0045] Take the overall 100g as the unit, add the amount of each component according to the above ratio, and prepare the special light-curing integrated color glue:

[0046] (1) Gradually add a dispersant to the divinyl monomer, and the stirring speed is controlled at 400 rpm;

[0047] (2) Add the divinyl monomer that has added the dispersant obtained in step (1) in the polyurethane acrylic resin, and the stirring speed is controlled at 200 revolutions / min; the viscosity of the main body mat...

Embodiment 3

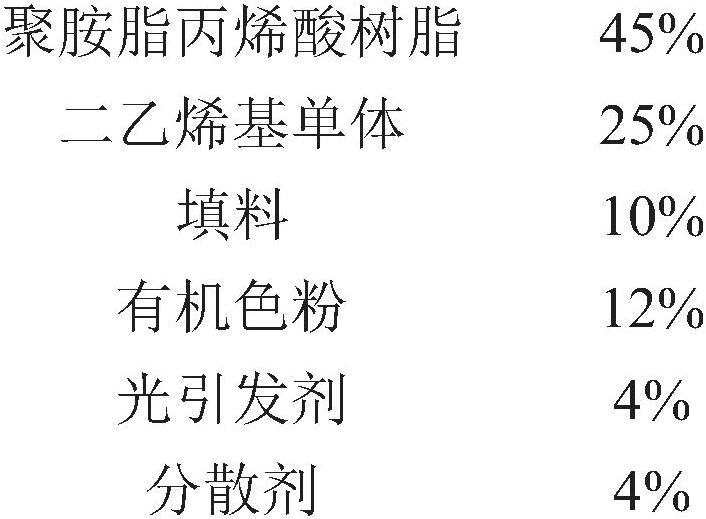

[0052] Deploying UV-curable color glue, including the following components in mass percentage:

[0053]

[0054] Wherein, the filler is: aluminosilicate (aluminum oxide: silicon oxide = 1: 1); the photoinitiator is: triaryl sulfonium hexafluorophosphate; the dispersant is acrylate and polyurethane (each accounting for 50% by mass); The organic toners are light fast red (red) and permanent yellow (yellow), which are respectively used as the positive and negative colors of the battery.

[0055] Take the overall 100g as the unit, add the amount of each component according to the above ratio, and prepare the special light-curing integrated color glue:

[0056] (1) Gradually add a dispersant to the divinyl monomer, and the stirring speed is controlled at 400 rpm;

[0057](2) Add the divinyl monomer that has added the dispersant obtained in step (1) in the polyurethane acrylic resin, and the stirring speed is controlled at 200 revolutions / min; the viscosity of the main body mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com