Silicon-based negative electrode material, and preparation method and application thereof

A silicon-based negative electrode material, silicon carbon technology, applied in the direction of negative electrodes, nanotechnology for materials and surface science, chemical instruments and methods, etc., can solve the problems of electrode loss of connectivity, active material fragmentation, cycle capacity attenuation, etc. , to achieve the effect of short synthesis time, simple method and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0058] According to one aspect of the invention, the present invention relates to a method of preparing a silicon-based negative electrode material comprising the steps of:

[0059] Silicon-carbon complex nannosphere powder, graphite and carbonized mixtures of carbonized materials are heated;

[0060] The preparation method of the silicon-carbon complex nannosphere powder includes: the gas-containing gas containing silicon-containing liquid precursor is pyrolysis to obtain a silicon oxide-carbon complex nannosphere powder, and then aluminum heat reduction.

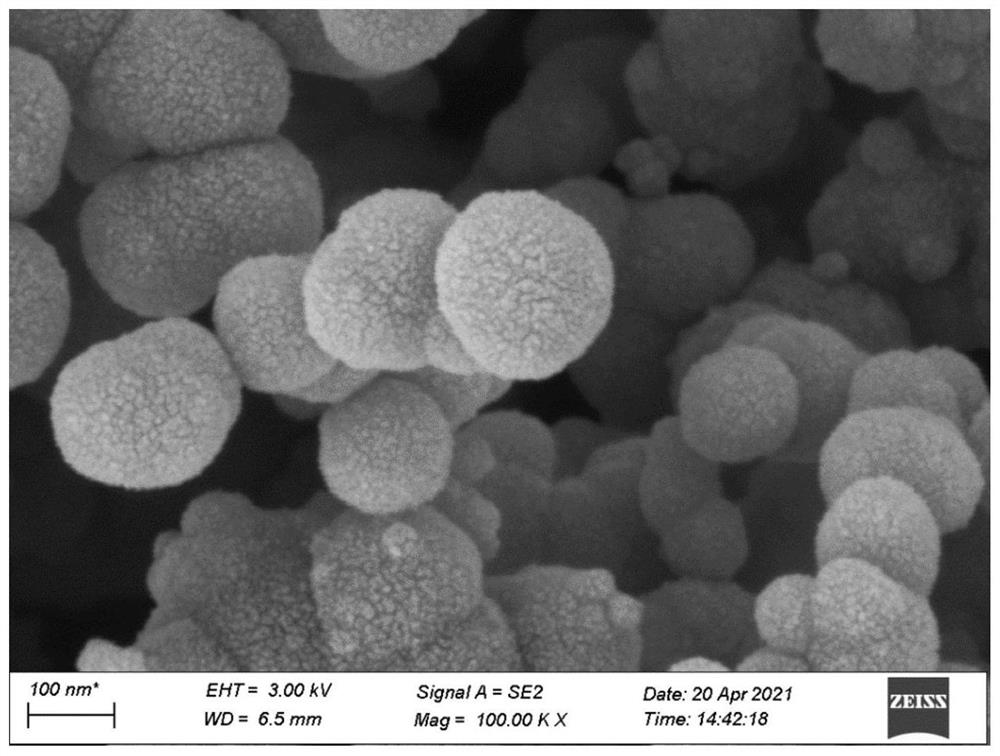

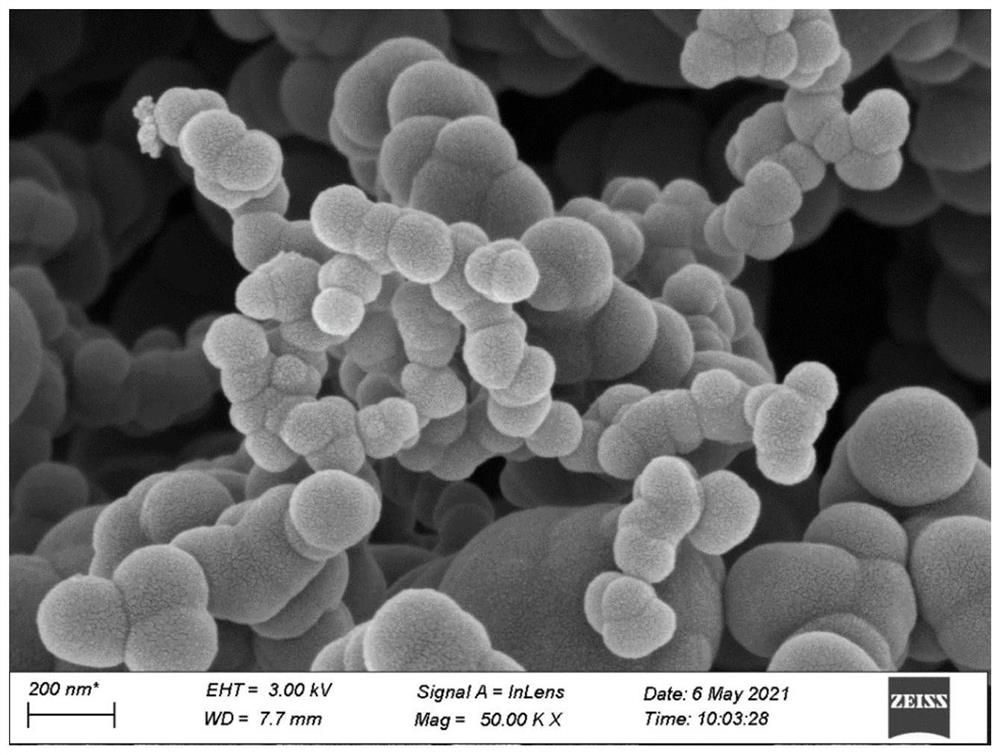

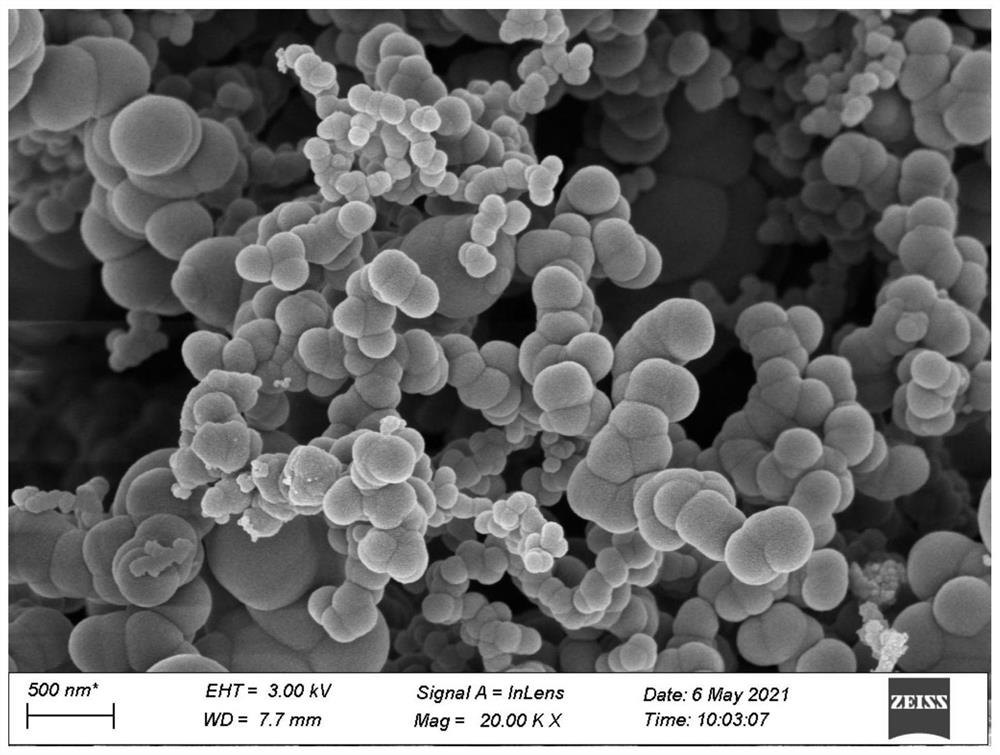

[0061] The present invention is a method for preparing silicon-carbon-carbon complex nanosphere powder using normal pressure chemical gas phase heat to prepare silicon-carbon carbon at home and abroad, and the silicon oxide-carbon complex nanosphere powder is in high pressure reactor. The aluminum heat reduction is carried out to obtain silicon-carbon complex nannosphere powder, and the silicon-carbon-carbon-carbon complex nan...

Embodiment 1

[0092] Silicon oxide-carbon complex nanosphere powder preparation method, including the following steps:

[0093] 3 ml of octamethylene trikoxane was heated to 300 ° C to evaporate, and the vapor flows into a tubular furnace having a temperature of 1020 ° C under the driving of the argon flow, and the thermosilicon-carbon compound is obtained after 4 hours. Nano spherical powder.

Embodiment 2

[0095] Silicon oxide-carbon complex nanosphere powder preparation method, including the following steps:

[0096] 4 ml of hexahydiloxane was heated to 50 ° C to evaporate, and its vapor flows into a tubular furnace at a temperature of 1100 ° C, and has an injection of 2 hours. After natural cooling, a silicon oxide-carbon compound is obtained. Nano spherical powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Compaction density | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com