Preparation method of low-cost battery-grade manganous-manganic oxide

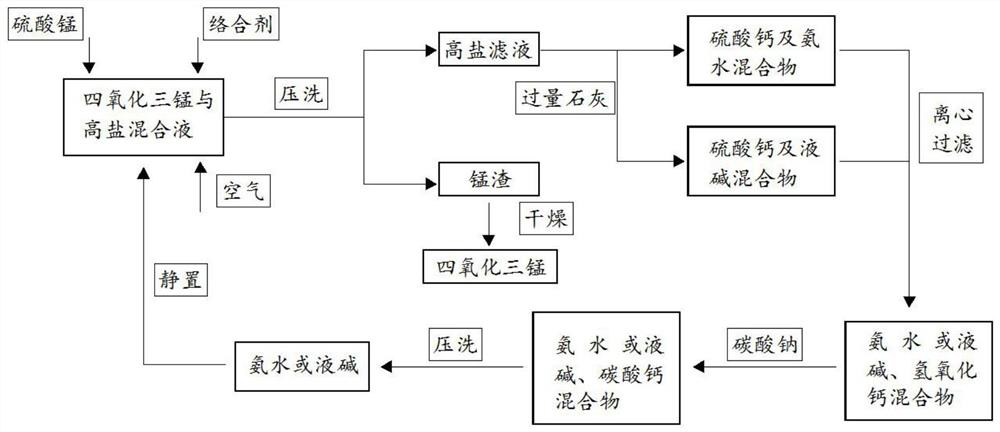

A technology of manganese tetroxide and battery grade, applied in the direction of manganese oxide/manganese hydroxide, etc., can solve the problems of high raw material cost of manganese tetroxide and large amount of waste water treatment, so as to reduce the solid liquid content and improve alkali recovery. rate, and the effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1: a kind of low-cost battery grade trimanganese tetraoxide preparation method, comprises the following steps:

[0032] 1) Take 14.2L of purified 100g / L manganese sulfate solution, add a certain amount of complexing agent, stir well and set aside, mark it as agent A, take 4L of 32% liquid caustic soda, mark it as agent B, and set aside;

[0033] 2) Add a certain amount of bottom liquid to the 30L synthesis tank, heat it to a certain temperature, and under the action of stirring, pump A and B agents into the synthesis tank at the same time through a peristaltic pump. During the process, a certain amount of air is introduced and controlled. pH value;

[0034] 3) After the synthesis is completed, the reaction mixture is subjected to solid-liquid separation, and the solid slag is washed and dried, marked as sample C, and the relevant indicators are detected;

[0035] 4) Take 10L of the filtrate separated in step 3, add 600g quicklime (excess lime), stir for a ce...

Embodiment 2

[0039] Embodiment 2: A method for preparing low-cost battery-grade trimanganese tetraoxide, comprising the following steps:

[0040] 1) Take 14.2L of purified 100g / L manganese sulfate solution, add a certain amount of complexing agent, stir well and set aside, mark it as agent A, take 8L of 50% ammonia, mark it as agent B, and set aside;

[0041] 2) Add a certain amount of base liquid to a 30L fully-sealed synthesis tank, heat it to a certain temperature, and under the action of stirring, pump A and B agents into the synthesis tank at the same time through a peristaltic pump, and a certain amount of air is introduced during the process. And control the pH value;

[0042] 3) After the synthesis is completed, the reaction mixture is subjected to solid-liquid separation, and the solid slag is washed and dried, marked as sample A, and the relevant indicators are detected;

[0043] 4) Take 10L of the filtrate separated in step 3, add 600g of quicklime (excess lime), and stir in a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com