Multi-layer one-time body composite manufacturing method of acryl plate

A production method and acrylic technology, applied in chemical instruments and methods, coatings, flat products, etc., can solve the problems of inability to produce polymethyl methacrylate sheets and production of acrylic sheets without extra-thick size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

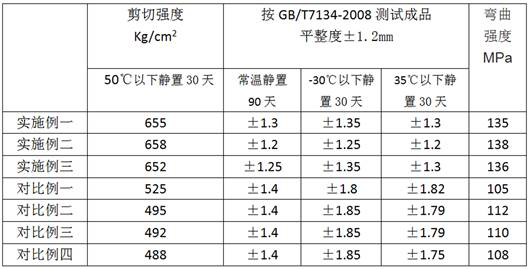

Examples

Embodiment 1

[0021] One kind of a multi-layer acrylic sheet composite body manufacturing method, comprising the steps of:

[0022] . A sheet production: mass include methyl methacrylate 100 parts, 10 acrylate, butyl acrylate 12, core-shell 8 stabilizers, acrylonitrile - styrene resin 9, an azobisisobutyronitrile, benzoyl peroxide carboxylate 2, KI560 blended polymeric coupling agent 1.2 for 40 minutes at 95 ℃, into a fixed mold formed acrylic sheet thickness 40mm;

[0023] . B Composite materials: parts by mass of methyl methacrylate comprising 100, 10 acrylate, butyl acrylate 12, core-shell 8 stabilizers, acrylonitrile - styrene resin 9, four 1.5 zinc oxide whisker, toluene 6-diisocyanate, 1-azobisisobutyronitrile, peroxide benzoate 2, KI560 polymerized at blending the coupling agent 1.2 95 ℃ 40 minutes to prepare a composite material slurry;

[0024] The above steps a, b of the core-shell parts by mass of a stabilizer comprising a styrene-butadiene latex 115nm 50, 10 of styrene, 2 of potassi...

Embodiment 2

[0034] One kind of a multi-layer acrylic sheet composite body manufacturing method, comprising the steps of:

[0035] . A sheet production: mass include methyl methacrylate 110 parts, 10.5 acrylate, butyl acrylate 14, 8.5 core-shell stabilizer, an acrylonitrile - styrene resin 10, 1.3 azobisisobutyronitrile, benzoyl peroxide carboxylate 1.6, KI560 blended polymeric coupling agent 1.25 55 minutes at 96 ℃, into a fixed mold formed acrylic sheet thickness 40mm;

[0036]b. Composite materials: According to the mass parts, methyl methacrylate 105, acrylic 10.5, butyl acrylate 13, nucleation shell stabilizer 9, acrylonitrile - styrene resin 10, four-needle-shaped zinc oxide 3, toluene Diisocyanate 8, azo diisobutyronitrile 1.3, metanoic acid methyl ester 2, Ki560 coupling agent 1.45 is blended at 100 ° C for 60 minutes, resulting in composite slurry;

[0037] The nuclear housing stabilizer of the above steps A, B includes 115 nm butadiene latex 70, styrene 11, potassium sulfate 2.5, dod...

Embodiment 3

[0047] A multi-layer primitive composite production method of acrylic sheet, including the following steps:

[0048] a. Plate production: According to the mass parts, methyl methacrylate 120, acrylic 12, butyl acrylate 15, nucleation shell stabilizer 10, acrylonitrile-styrene resin 11, azo diisobutyronitrile 1.5, sternetic oxide Methyl formate 3, Ki560 coupling agent 1.5 is blended at 95 ° C for 60 minutes, and the molded mold is fed into a stexical sheet having a fixed plate thickness of 40 mm;

[0049] b. Composite materials: According to the mass parts of methacrylate 120, acrylic 12, acrylate 15, nuclear shell stabilizer 10, acrylonitrile-styrene resin 11, four-needle-shaped zinc oxide crystal 2.5, toluene Diisocyanate 10, azo diisobutyronitrile 1.5, meta-oxide chiphenoid 3, Ki560 coupling agent 1.5 is blended at 100 ° C for 60 minutes, resulting in composite slurry;

[0050] The nuclear housing stabilizer of the above steps A, B includes 120 nm butadiene latex 80, styrene 12,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com